Method of polishing transparent armor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

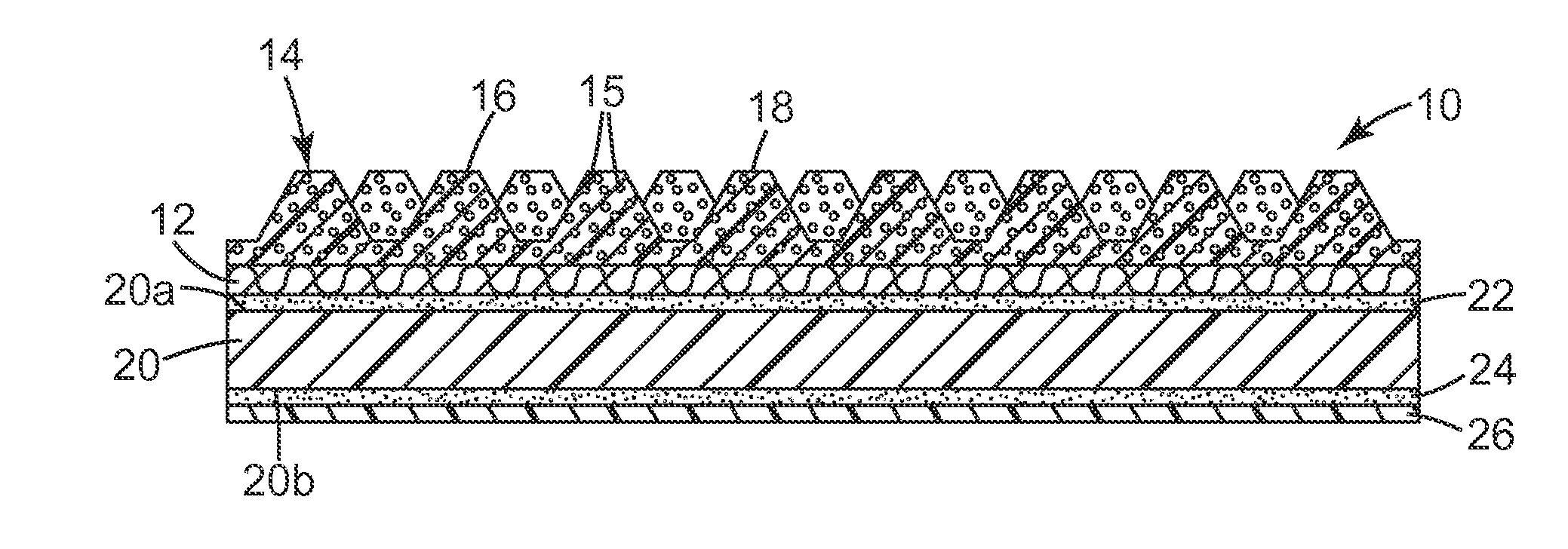

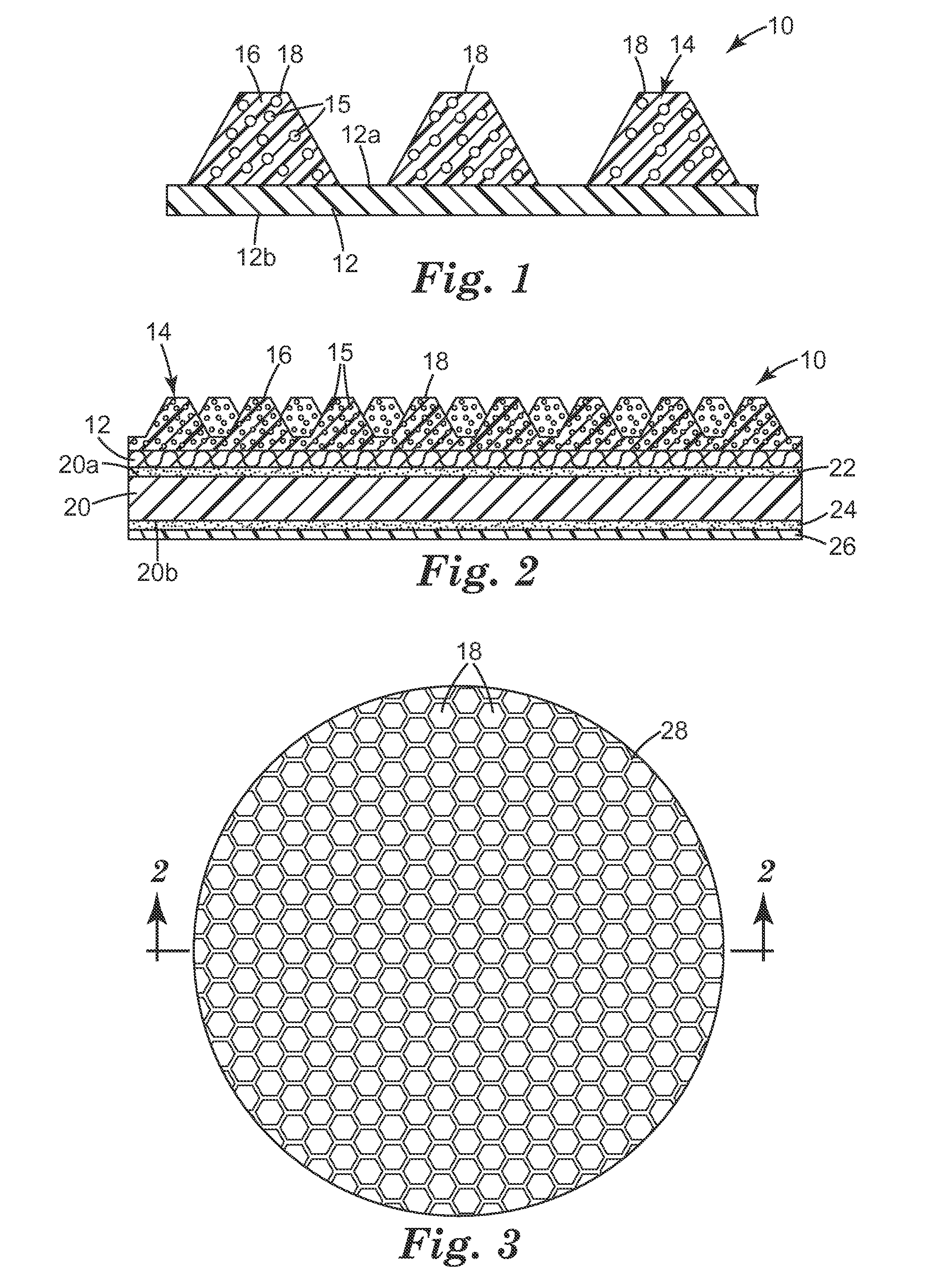

[0116]Abrasive article Example 1 listed in Table 3 was prepared according to Method 2, and included 9 μm vitrified agglomerate abrasive particles prepared according to Method 1. Example 1 was used to grind spinel ceramic test samples according to Method 3 and resulting surface finishes were measured according to Method 4. Test results are summarized in Table 4. Example 1 comprised hexagonal shaped abrasive composites having an abrasive diamond content of 7.00 weight percent, 2.22 shaped abrasive composites per linear cm, 5.37 shaped abrasive composites per cm2 and a bearing area ratio of 58.0 percent.

examples 2-4

[0117]Abrasive article Examples 2-4 listed in Table 3 were prepared according to Method 2. Examples 2-4 were used to grind spinel ceramic test samples according to Method 3 and resulting surface finishes were measured according to Method 4. Test results are summarized in Table 4.

[0118]Example 2 comprised hexagonal shaped abrasive composites having an abrasive diamond content of 27.60 weight percent, 2.33 shaped abrasive composites per linear cm, 6.12 shaped abrasive composites per cm2, and a bearing area ratio of 64.0 percent.

[0119]Example 3 comprised hexagonal shaped abrasive composites having an abrasive diamond content of 26.20 weight percent, 2.33 shaped abrasive composites per linear cm, 6.12 shaped abrasive composites per cm2, and a bearing area ratio of 64.0 percent.

[0120]Example 4 comprised hexagonal shaped abrasive composites having an abrasive diamond content of 25.70 weight percent, 2.33 shaped abrasive composites per linear cm, 6.12 shaped abrasive composites per cm2, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com