Electrostatic dissipative garment with interchangeable elastic bands

a technology of electric shock and elastic bands, applied in the field of electric shock dissipative coatlike outer garments, can solve the problems of whole smock replacement, body to ground system failure, etc., and achieve the effect of extending the durability and usable shelf life of an esd smock and easy attachment and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

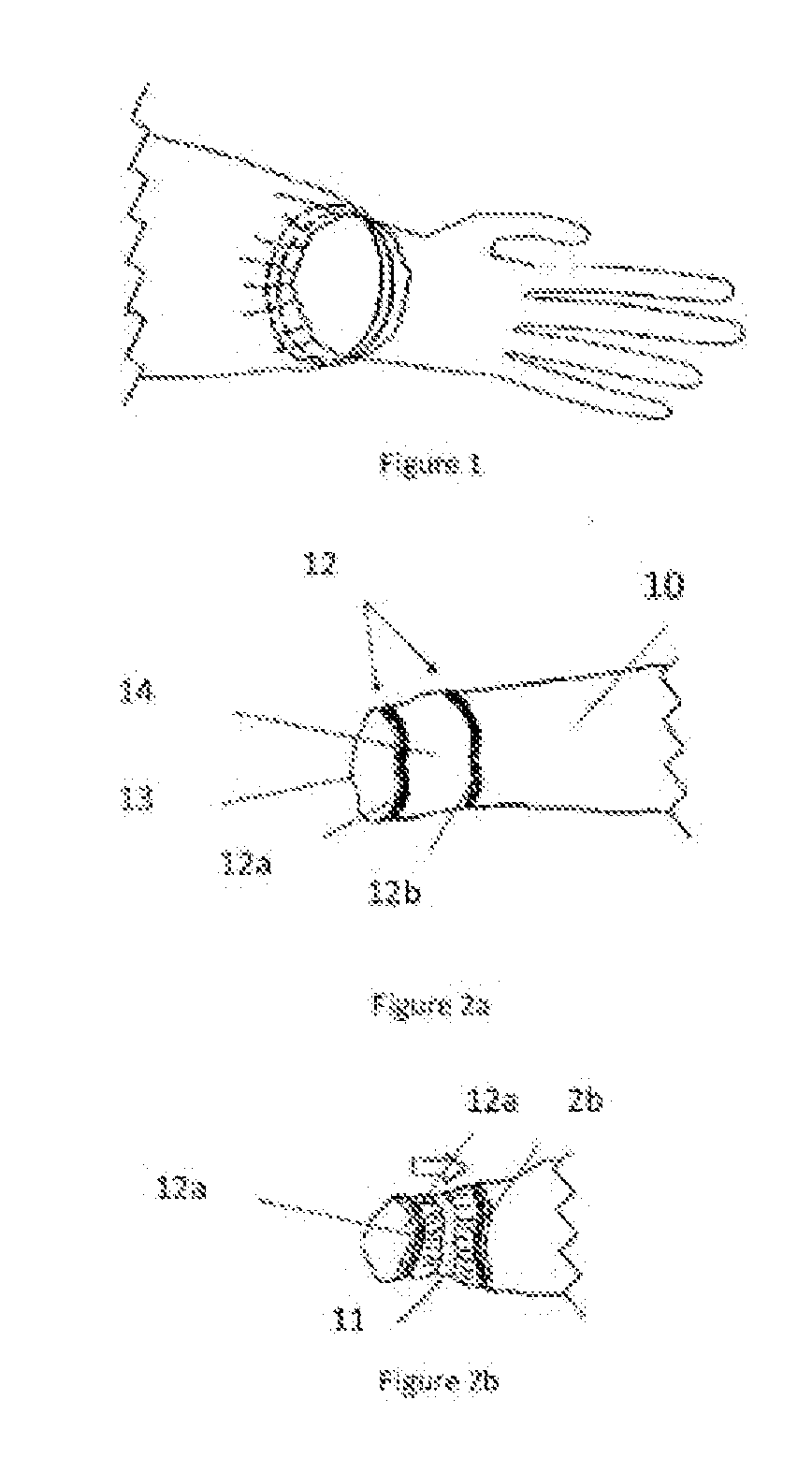

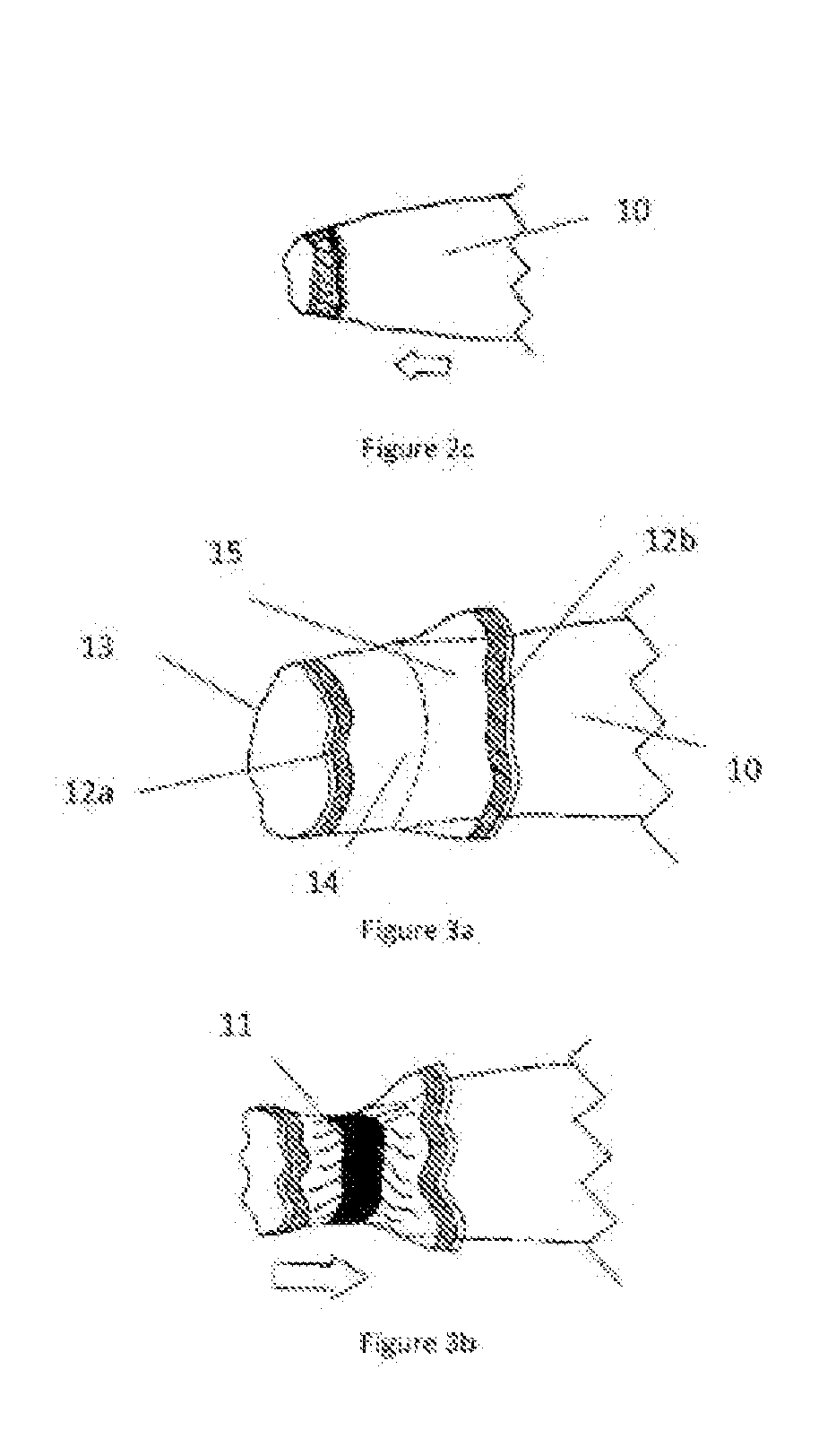

[0027]FIG. 2 shows the end-most portion sleeve (10) of an electrostatic dissipative smock having a replaceable elastic wrist band (11) of the first embodiment of the present invention. A pair of attachment means (12) with its first attachment means (12a) located adjacent to the end-most opening (13) of the sleeve (10) and its second matching attachment means (12b) located at a distance away from the first attachment means (12a) of the sleeve (10), thereby providing a space gap (14) in between the first (12a) and second (12b) attachment means to allow the elastic wrist band (11) to be looped over thereon. The attachment means (12) could be any suitable attachment means that are able to attach together for enclosing the wrist band(11) at the space gap (14) such as Velco tapes, snap-on buttons, standard buttons, zipper type fastener, etc. For the zipper type fastener, it consists of a pair of interlocking components that enabling resealing and unsealing of the fastener. The preferred a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com