Low viscosity engine oil with superior engine wear protection

a low viscosity, engine oil technology, applied in the direction of additives, lubricant compositions, liquid carbonaceous fuels, etc., can solve the problems of increased engine wear, inability to provide acceptable passenger vehicle diesel engine durability performance, and diesel engines are more prone to filter plugging, so as to improve fuel economy and improve anti-wear performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

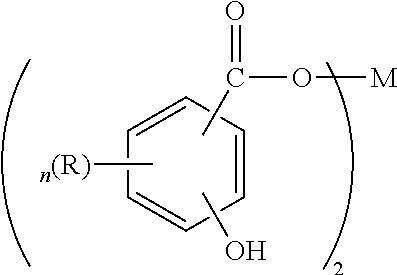

Image

Examples

Embodiment Construction

[0010]It has now been found that an engine oil lubricant composition comprising a major amount of base oil and an effective amount of a zinc dialkyl dithio phosphate, a polymeric viscosity index improver and a mixture of alkaline earth metal detergents provides improved fuel efficiency while providing excellent wear in an engine. The engine oil lubricant composition has a sulfated ash content of less than about 0.8 wt % and an HTHS of less than about 2.9 cP at 150° C.

[0011]A wide range of lubricating base oils is known in the art. Lubricating base oils that are useful in the present invention are both natural oils, and synthetic oils, and unconventional oils (or mixtures thereof) can be used unrefined, refined, or rerefined (the latter is also known as reclaimed or reprocessed oil). Unrefined oils are those obtained directly from a natural or synthetic source and used without added purification. These include shale oil obtained directly from retorting operations, petroleum oil obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com