Self-Aligning and Leak Monitoring Stuffing Box

a self-aligning and leak-monitoring technology, which is applied in the direction of drilling casings, drilling pipes, borehole/well accessories, etc., can solve the problems of wear between the flanges, less robust means of compensating, and no backup system is provided for preventing leakage, so as to achieve reliable and robust stuffing box assemblies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

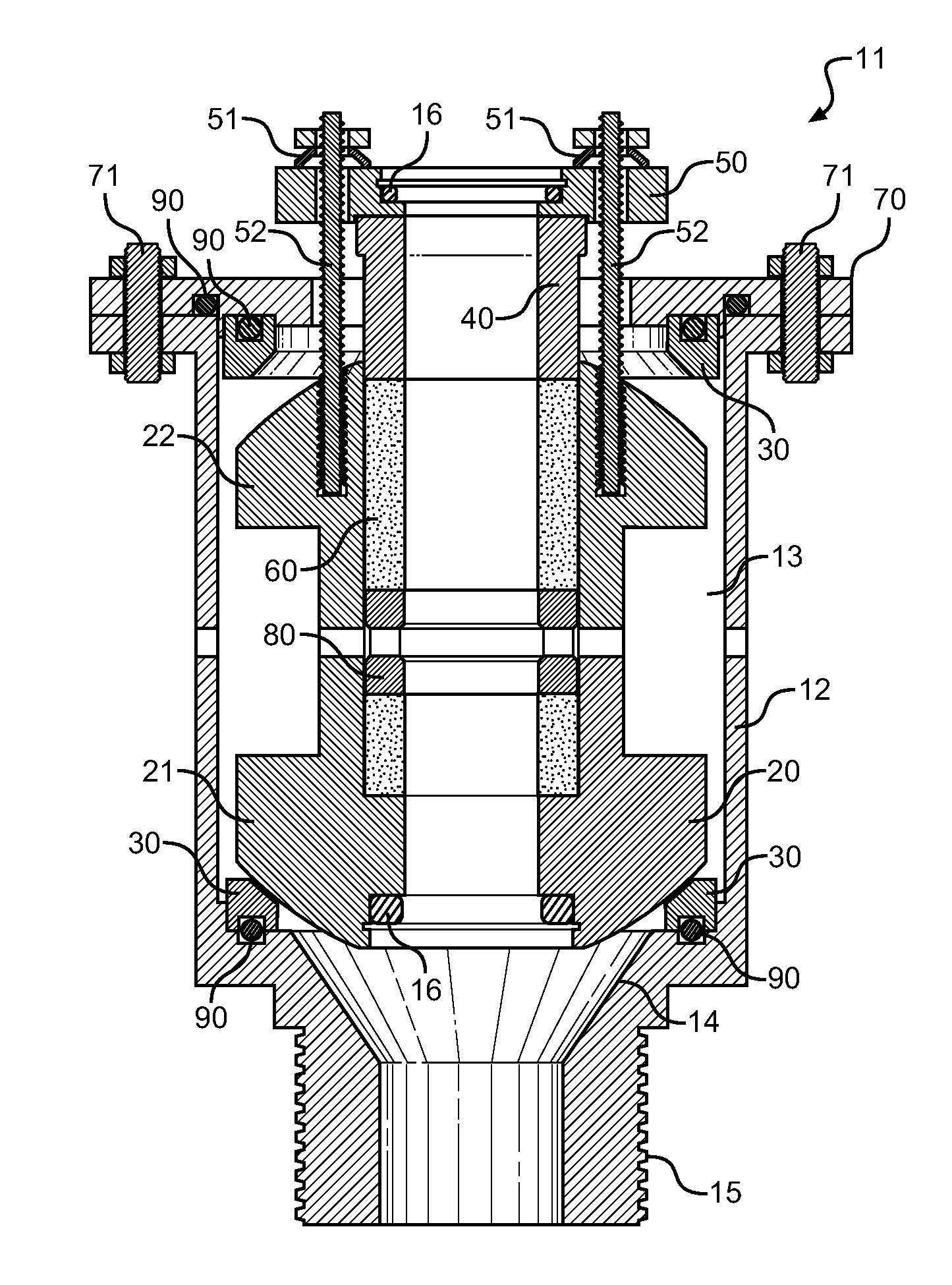

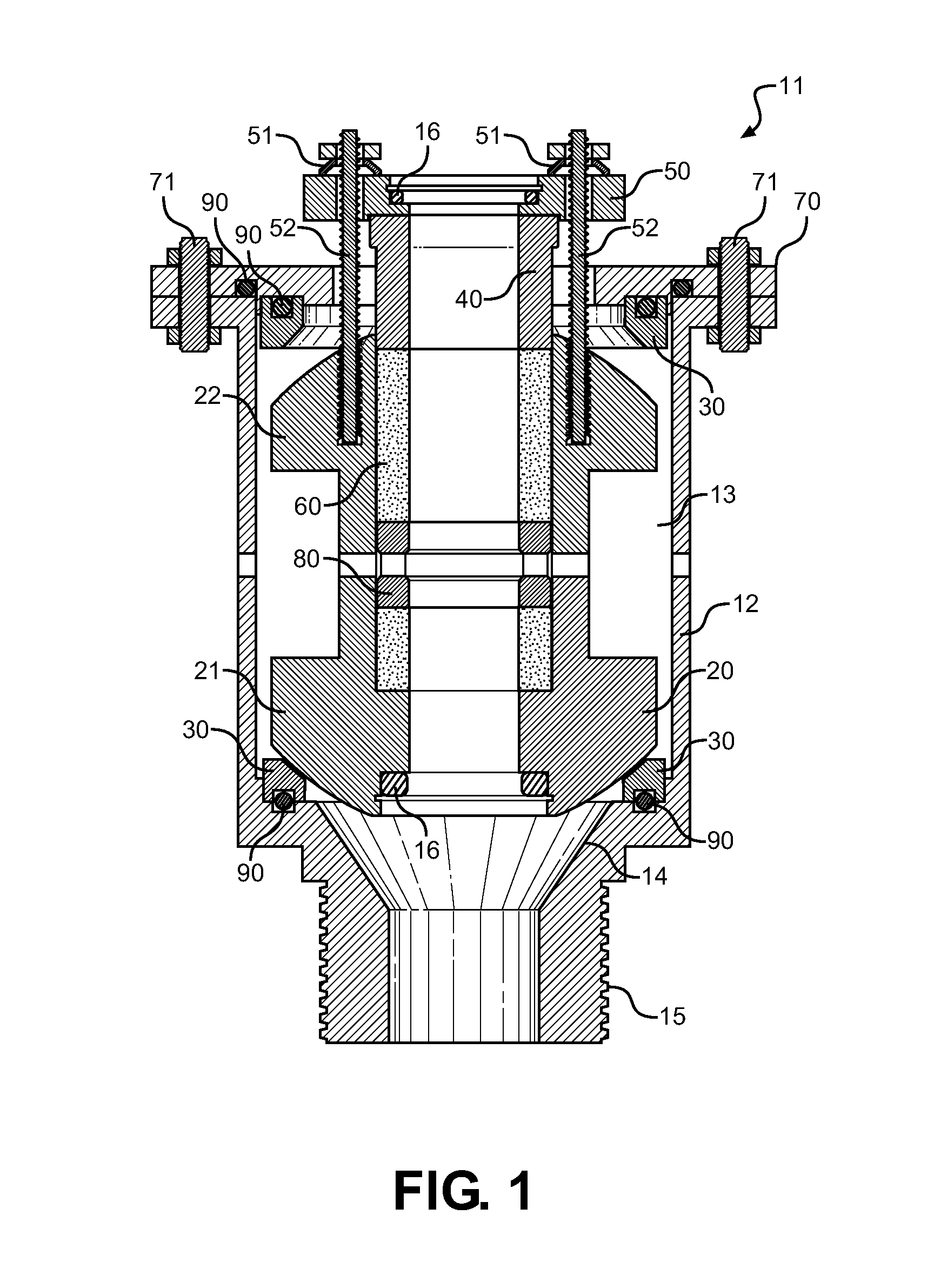

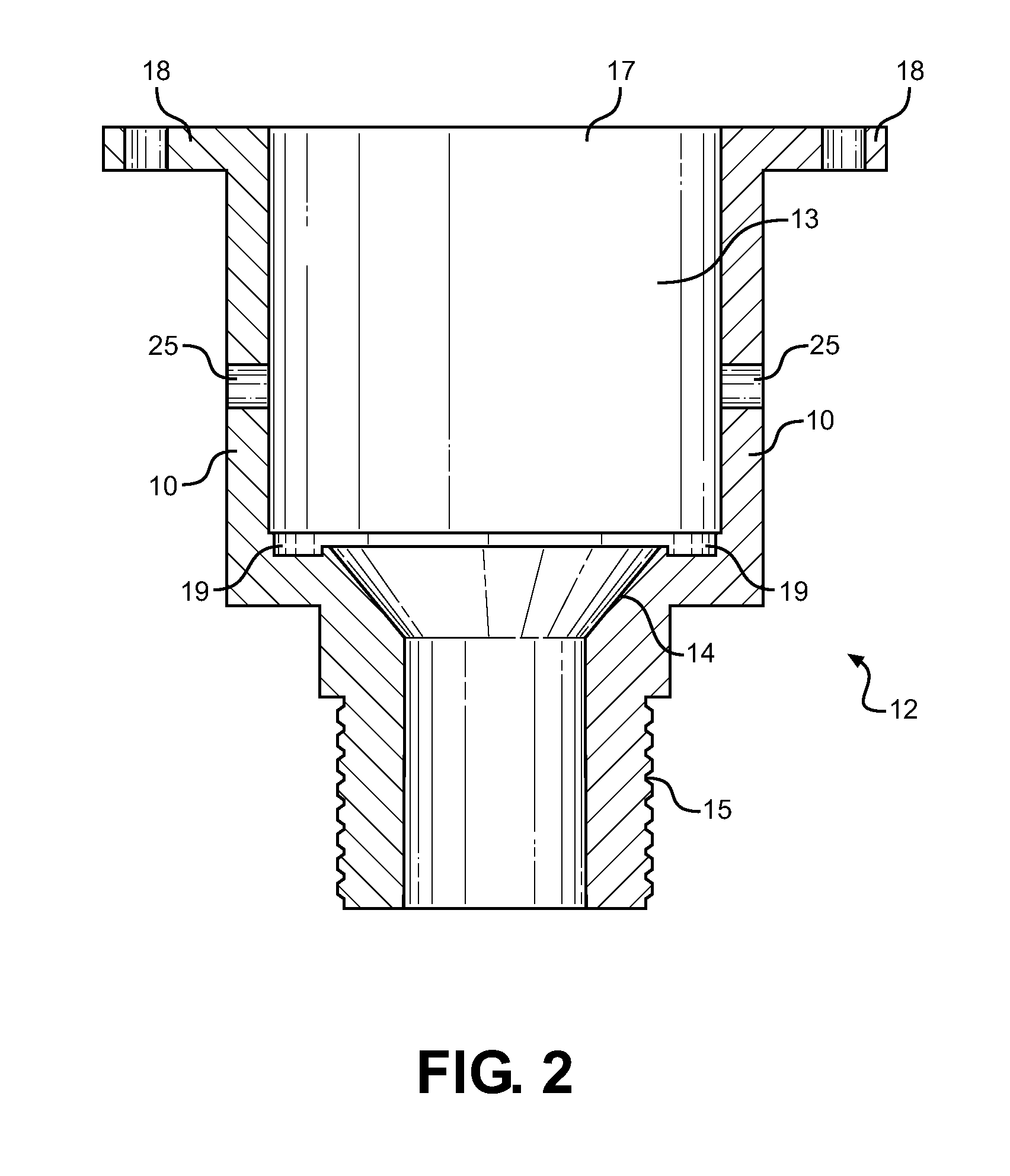

[0038]Reference is made herein to the attached drawings. Like reference numerals are used throughout the drawings to depict like or similar elements of the stuffing box. For the purposes of presenting a brief and clear description of the present invention, the preferred embodiment will be discussed as used for preventing misalignment of a polished rod with respect to the stuffing box, reducing wear, preventing contamination, preventing corrosion and detecting leaks as they occur within the housing. The figures are intended for representative purposes only and should not be considered to be limiting in any respect.

[0039]Referring now to FIG. 1, there is shown a cross section view of the stuffing box assembly 11 of the present invention. The assembly comprises a housing body 12 having an open interior volume 13 adapted to accept a rotating stuffing box device 20 therein. The interior of the housing body 13 comprises a beveled or contoured surface 14 and a contour seat 30 that comprise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com