Washing Machine Drive System

a technology for driving systems and washing machines, applied in other washing machines, domestic applications, textiles and paper, etc., can solve the problems of long service life of the drive motor, large volume, complex structure of the drive mechanism, etc., and achieve the effect of reliable performance and simple structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

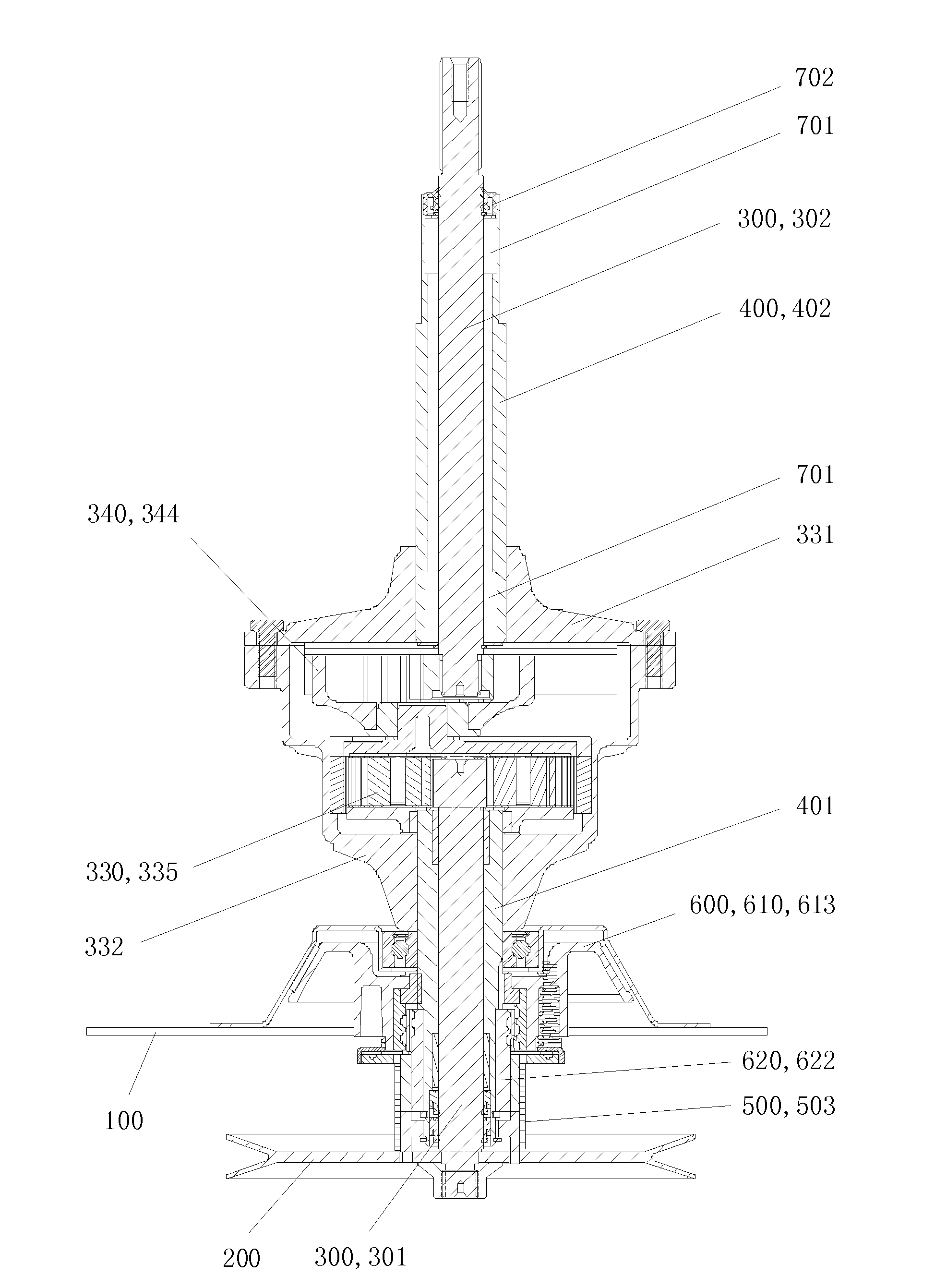

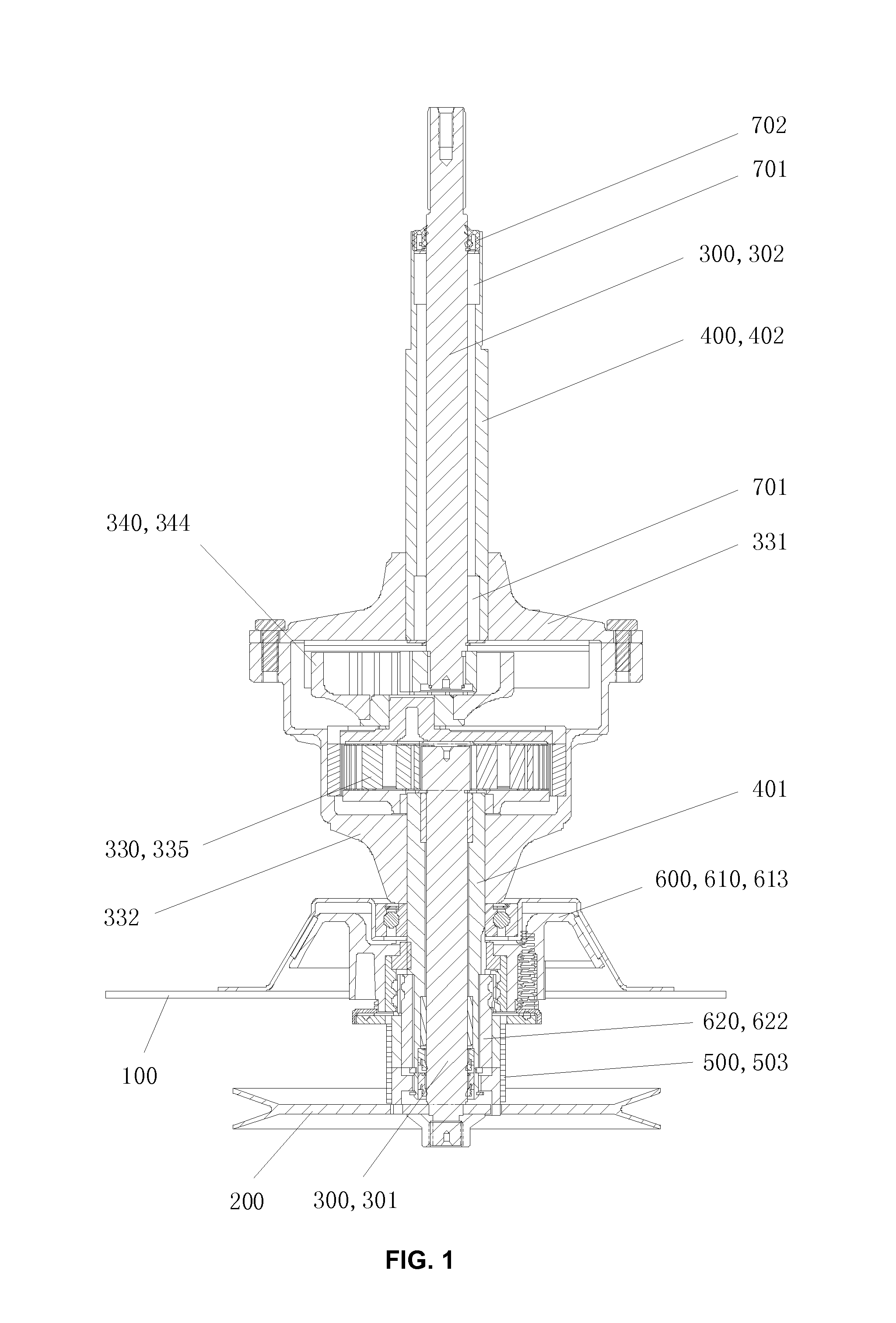

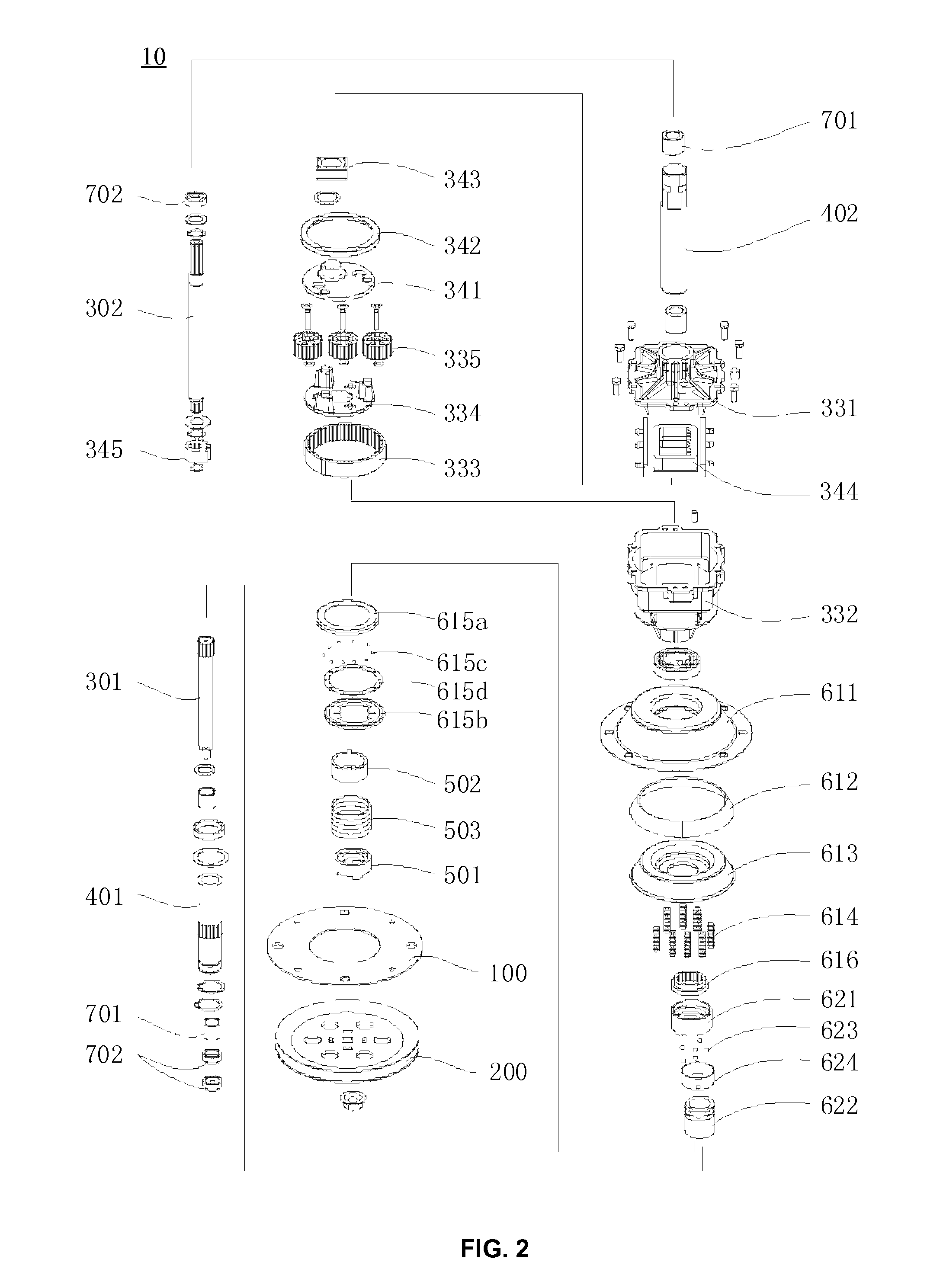

[0037]As shown in FIG. 1-3, the present invention includes a mounting plate 100 connecting to the body of the washer, a driving pulley 200, a main shaft assembly 300, a sleeve shaft assembly 400, a clutch 500, and a brake module 600. The lower part of main shaft assembly 300 is connecting to the driving pulley 200. The sleeve shaft assembly 400 and main shaft assembly 300 are coaxially arranged and can rotate with respect to each other. The lower end of the sleeve shaft assembly 400 is connected with driving pulley 200 through the clutch 500.

[0038]The main shaft assembly 300 includes an input shaft 301 and an output shaft 302. A planetary gear module 330 and an oscillating drive output module 340 are configured between the input shaft 301 and the output shaft 302. The braking module 600 includes a cone-shaped brake unit 610 and a braking control unit 620.

[0039]The brake unit 610 includes a cone flange 611 fastened to the mounting plate 100, a brake pad 612 lining at the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com