Work vehicle fluid heating system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

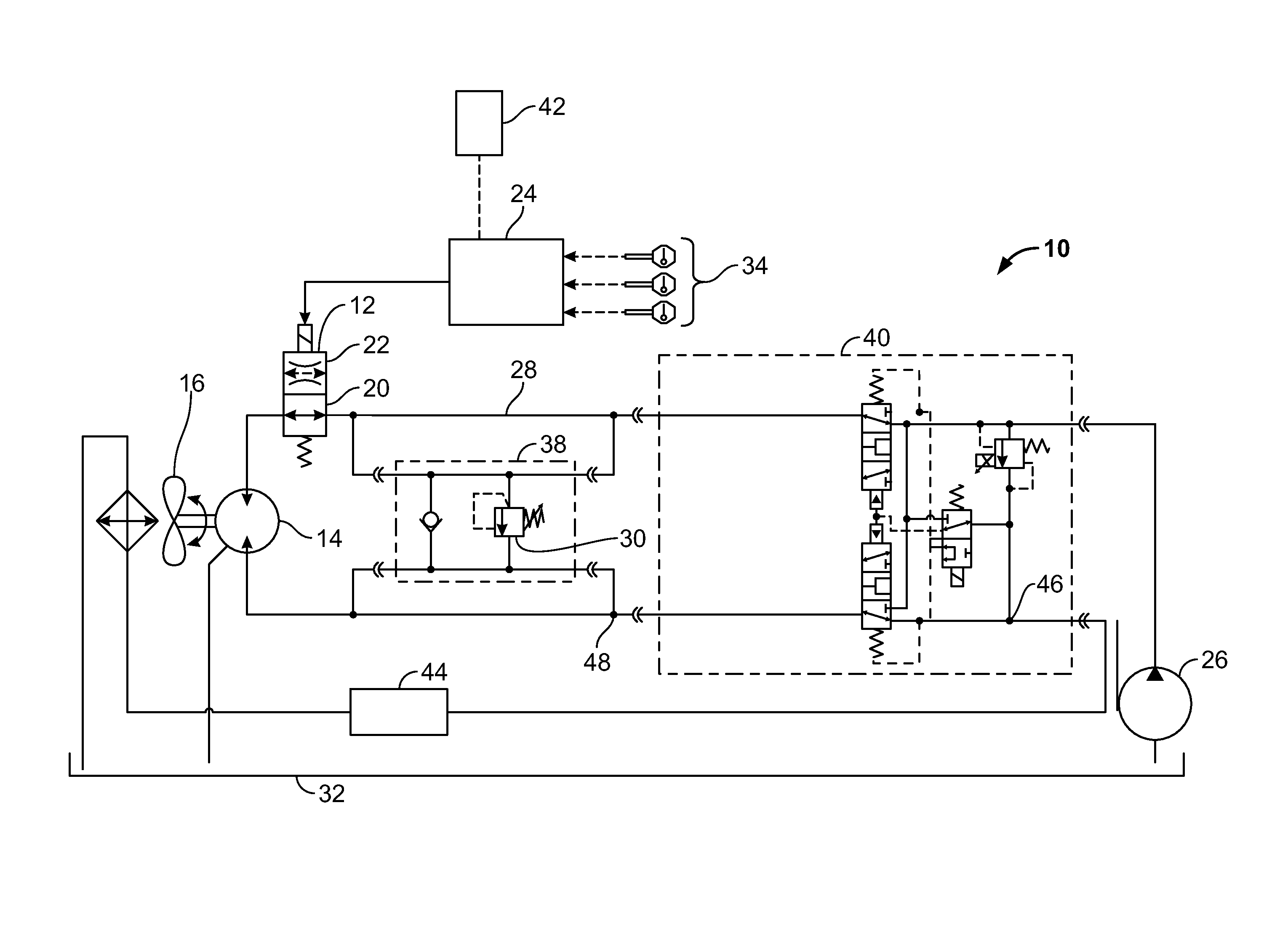

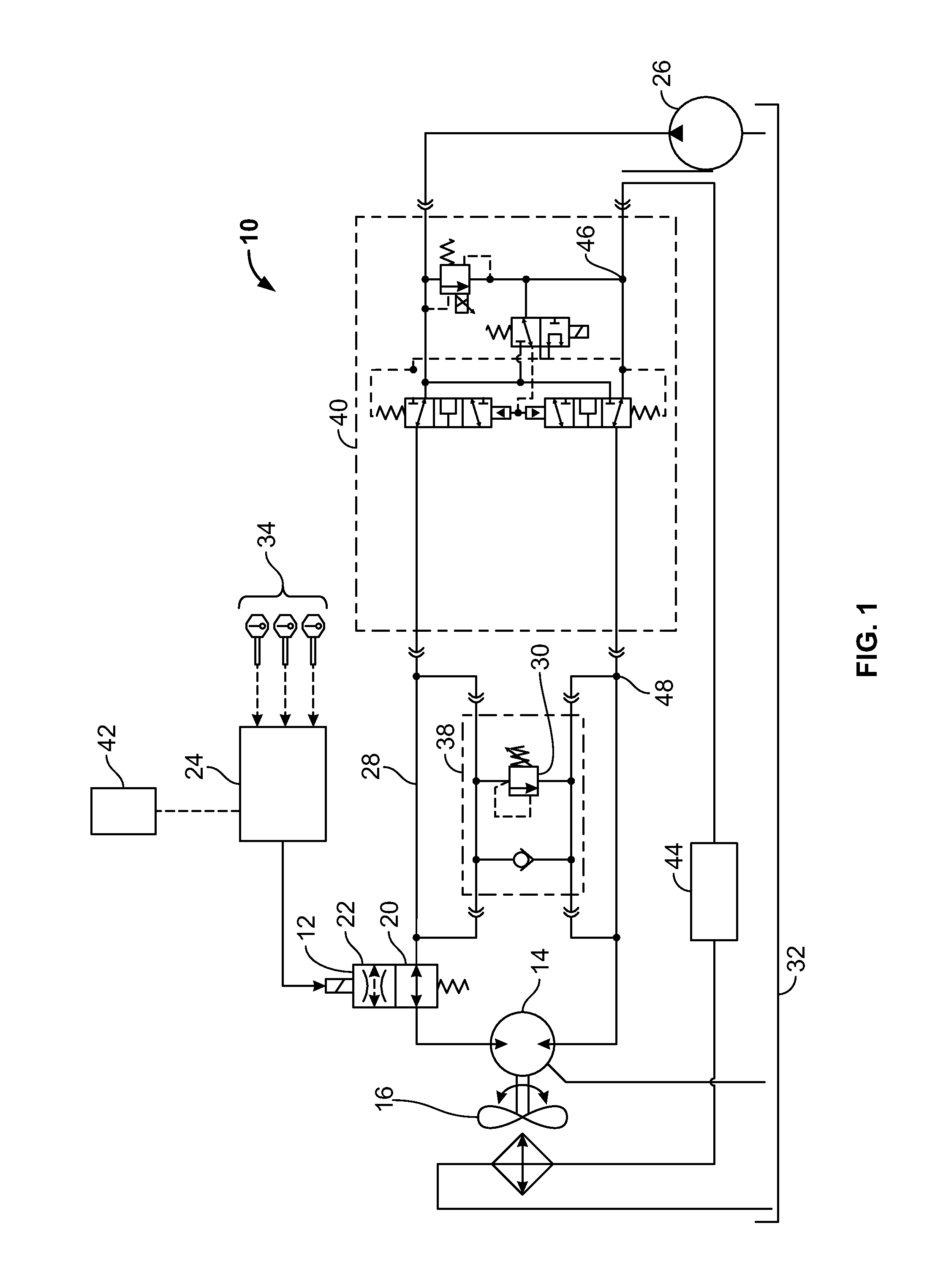

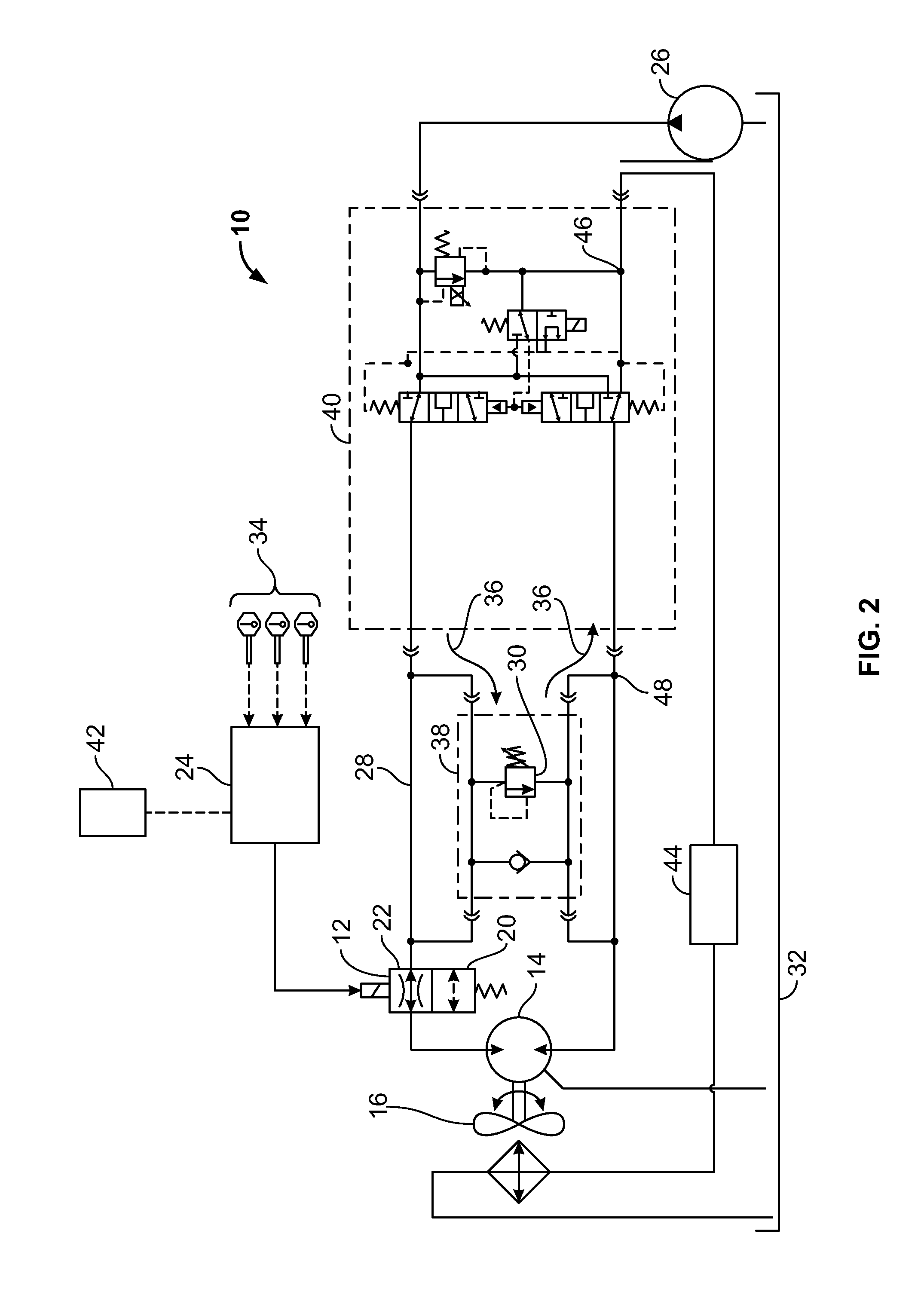

[0014]Referring to the drawings, FIGS. 1-2 show schematic representations of an exemplary embodiment of the present disclosure. FIG. 1 shows a fluid heating system 10 including a control device 12, such as a digitally controlled solenoid valve having a first position 20 and a second position 22. Control device 12 is controlled by a control module 24 that receives input signals from sensors 34 associated with temperatures and / or other component / system / subsystem operating parameters. Under normal operating conditions, such as when the ambient temperature is greater than a predetermined minimum temperature, such as 90° C. in one application, and in combination with other parameters in other applications such as discussed in further detail below, hydraulic pump 26 provides pressurized hydraulic oil to a fluid circuit 28. In response to sensors 34 controlled by control module 24 sensing the temperature of the hydraulic oil in fluid circuit 28, as well as other temperature / parameters as d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap