Multilayer heat exchanger and heat exchange system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

(Outline of Heat Exchange System)

[0028]With reference to the drawings, a heat exchange system according to a first embodiment of the present invention will be described.

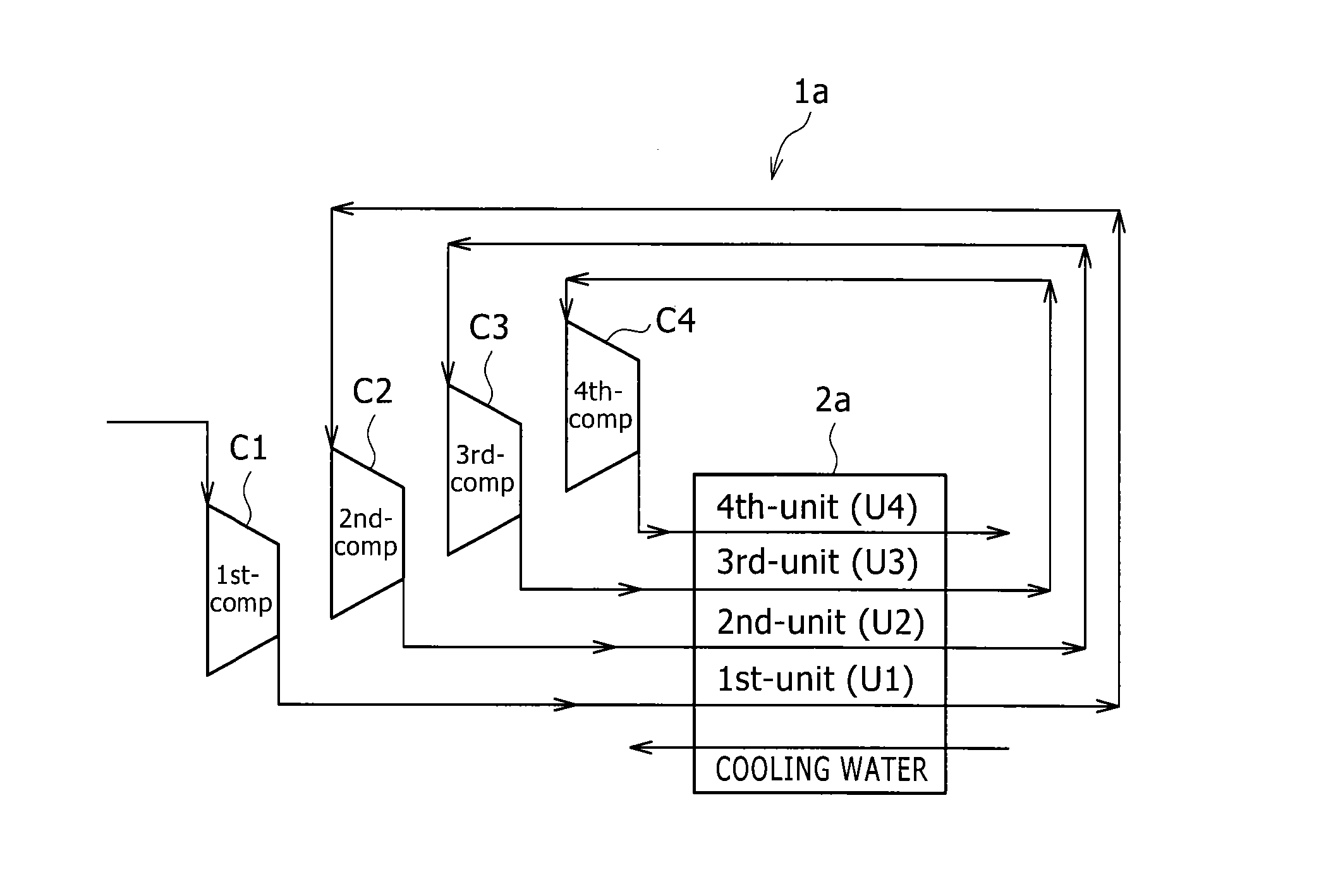

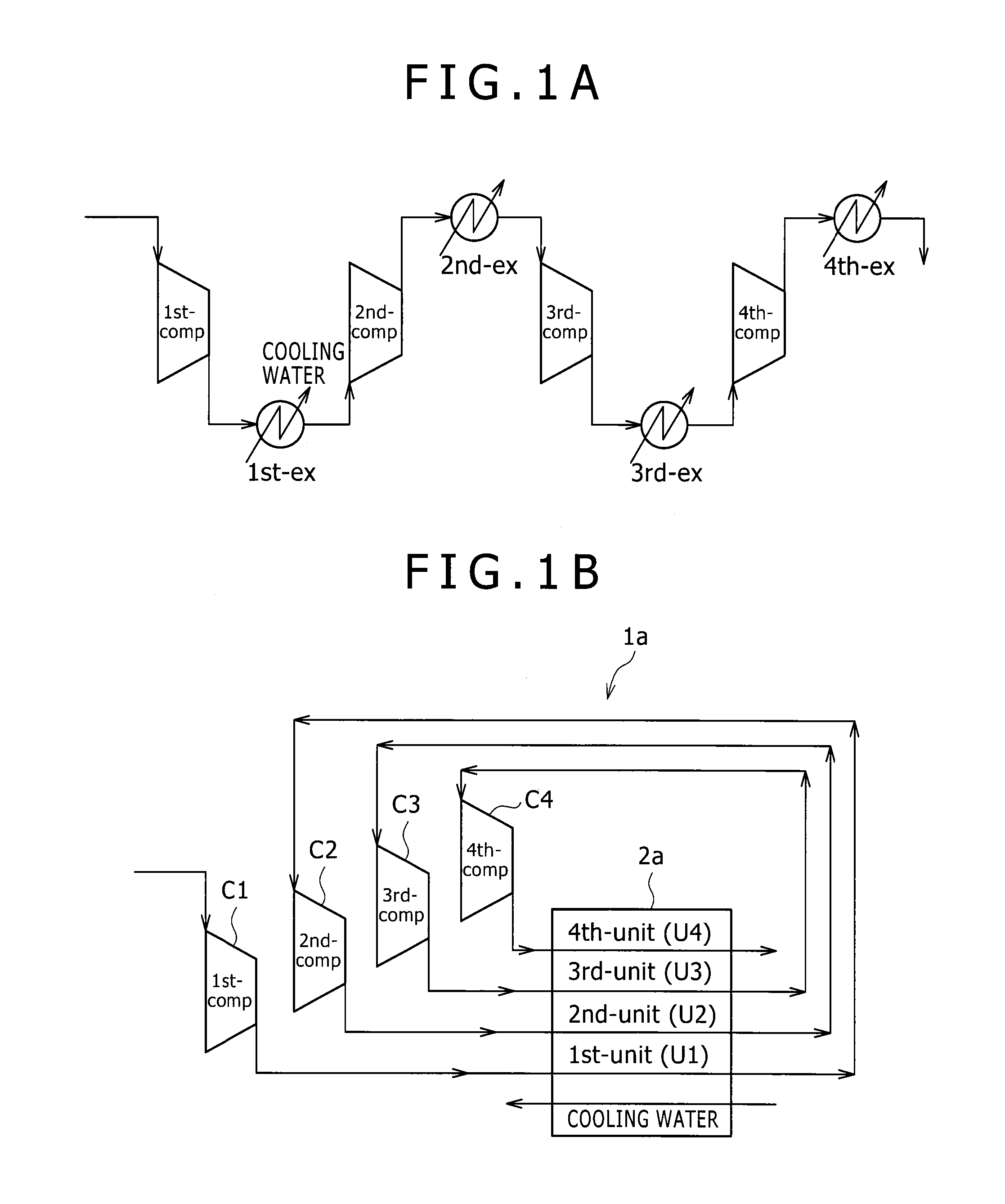

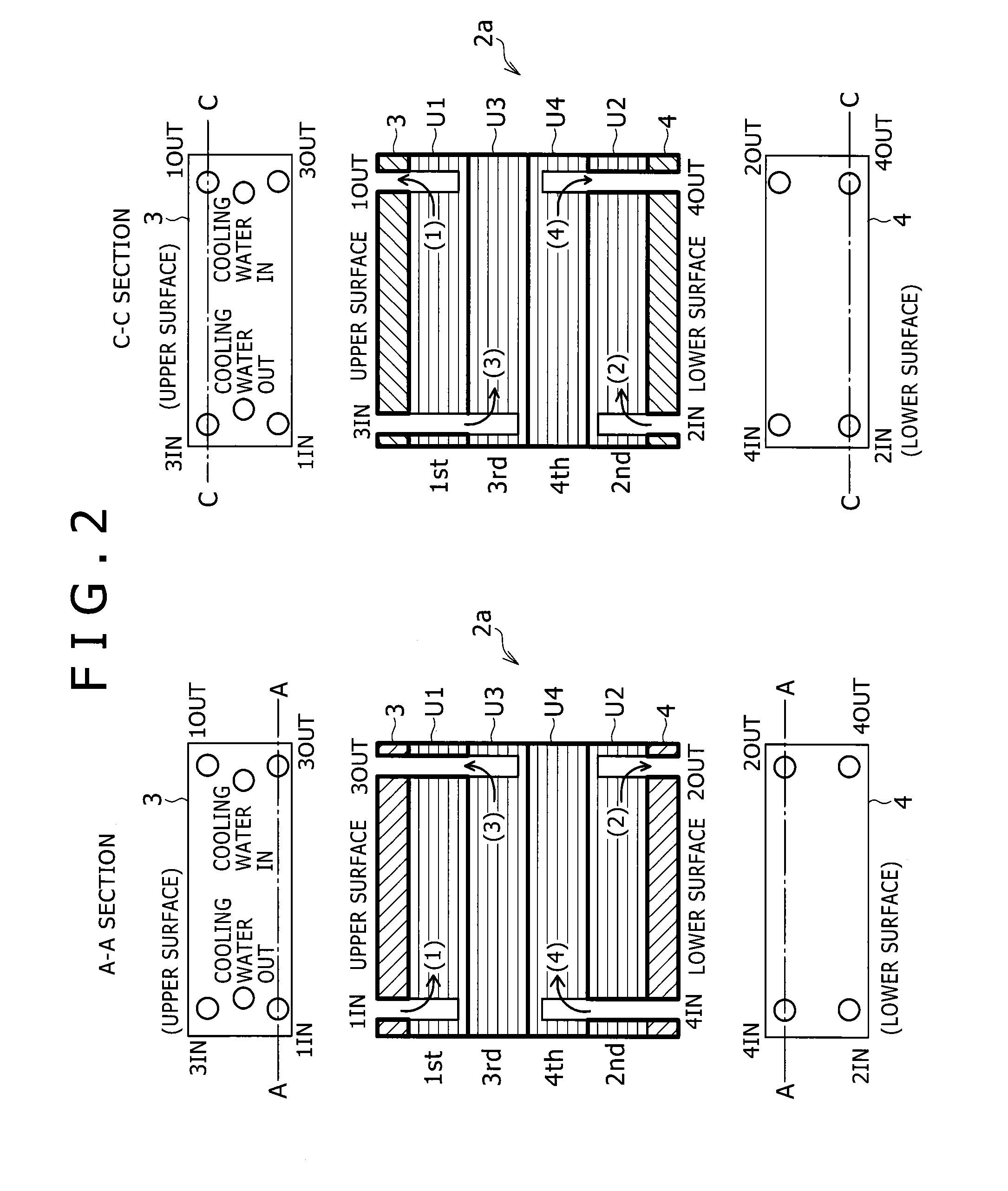

[0029]FIG. 1 is a concept view showing a configuration of a multi-step type heat exchange system in which compressors serving as a plurality of machines and a plurality of heat exchangers are used. FIG. 1A is a concept view showing a configuration of a heat exchange system in which conventional heat exchangers are used, and FIG. 1B is a concept view showing a configuration of a heat exchange system 1a in which a multilayer heat exchanger 2a according to the present embodiment is used.

[0030]In the heat exchange system 1a to be described in the present embodiment, in a multi-step type compression process for successively pressurizing and compressing a gas by a plurality of compressors connected in series so as to change the gas into a high-pressure gas, the heat exchanger is provided in a subsequent step to the compres...

second embodiment

[0105]With reference to FIGS. 7 to 9, a heat exchange system 1b according to a second embodiment of the present invention will be described.

[0106]In the heat exchange system 1b according to the present embodiment, six compressors C1 to C6 and six heat exchange units U1 to U6 are connected in series so as to perform a six-step compression. That is, a configuration of a multilayer heat exchanger 2b formed by stacking the six heat exchange units U1 to U6 is different from the configuration of the multilayer heat exchanger 2a according to the first embodiment. Thus, the configuration will be described in detail below.

[0107]The multilayer heat exchanger 2b according to the present embodiment is different from the multilayer heat exchanger 2a according to the first embodiment in terms that a configuration of a cooling plate CP2 is different from the cooling plate CP1 of the multilayer heat exchanger 2a according to the first embodiment, and the fifth heat exchange unit U5 and the sixth he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com