Liquid metal ion source and secondary ion mass spectrometric method and use thereof

a technology of liquid metal ion and mass spectrometry, which is applied in the field of secondary ion mass spectrometric analysis methods, secondary ion mass spectrometers, and liquid metal ion sources, which can solve the problems of limited acceptance of date only, increasing the difficulty of building a spectrum library, and affecting the experimental complexity of this method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

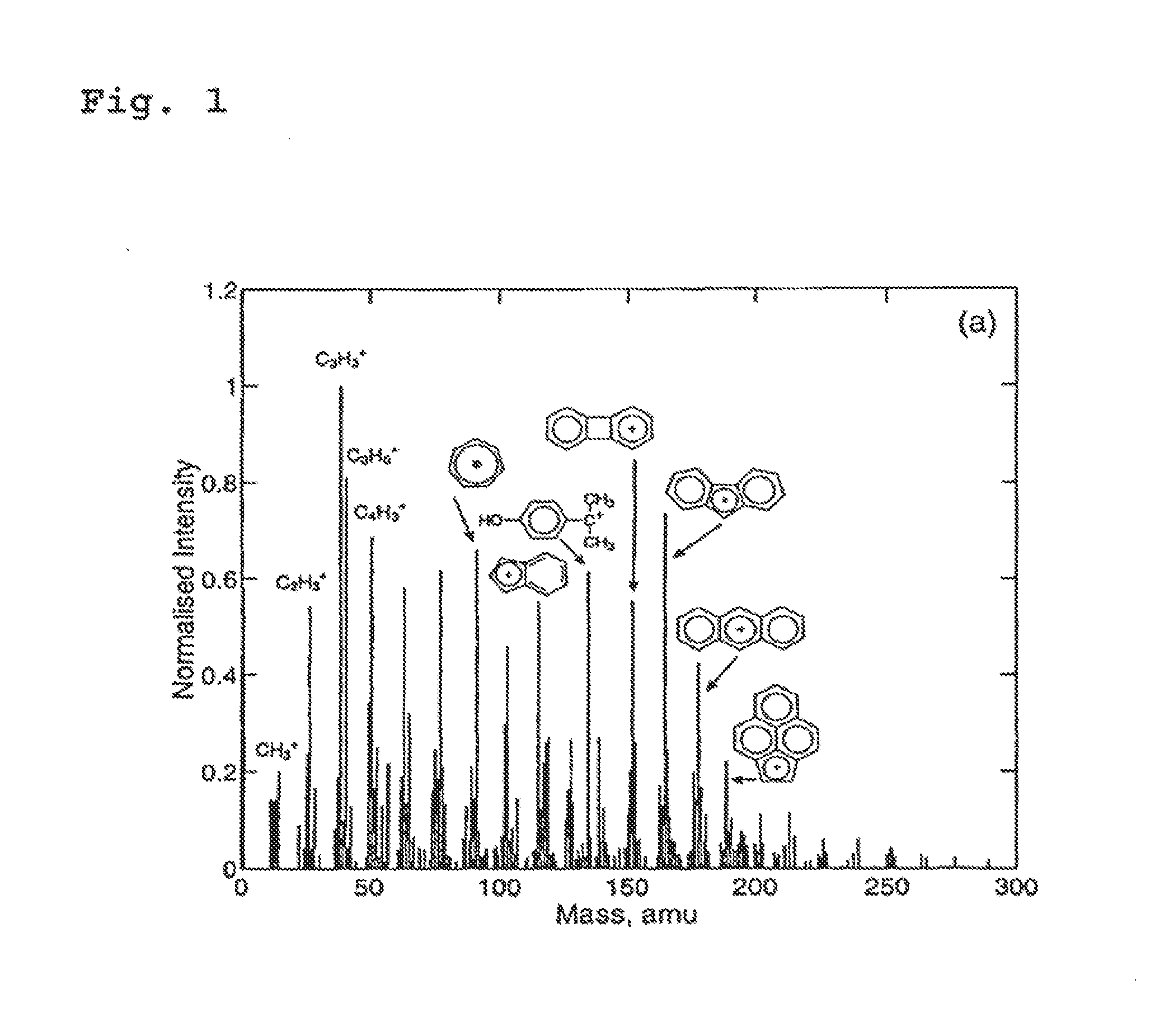

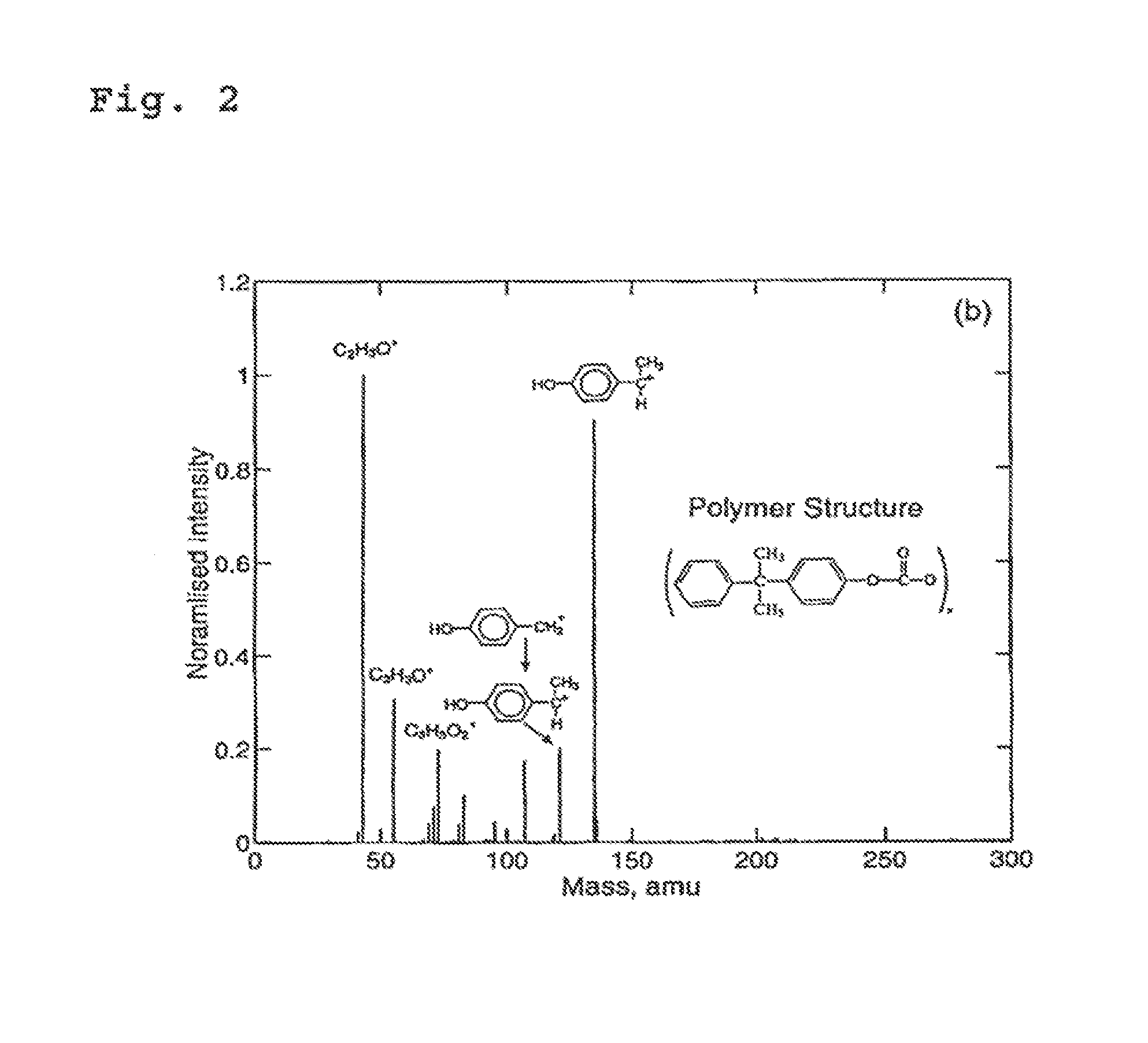

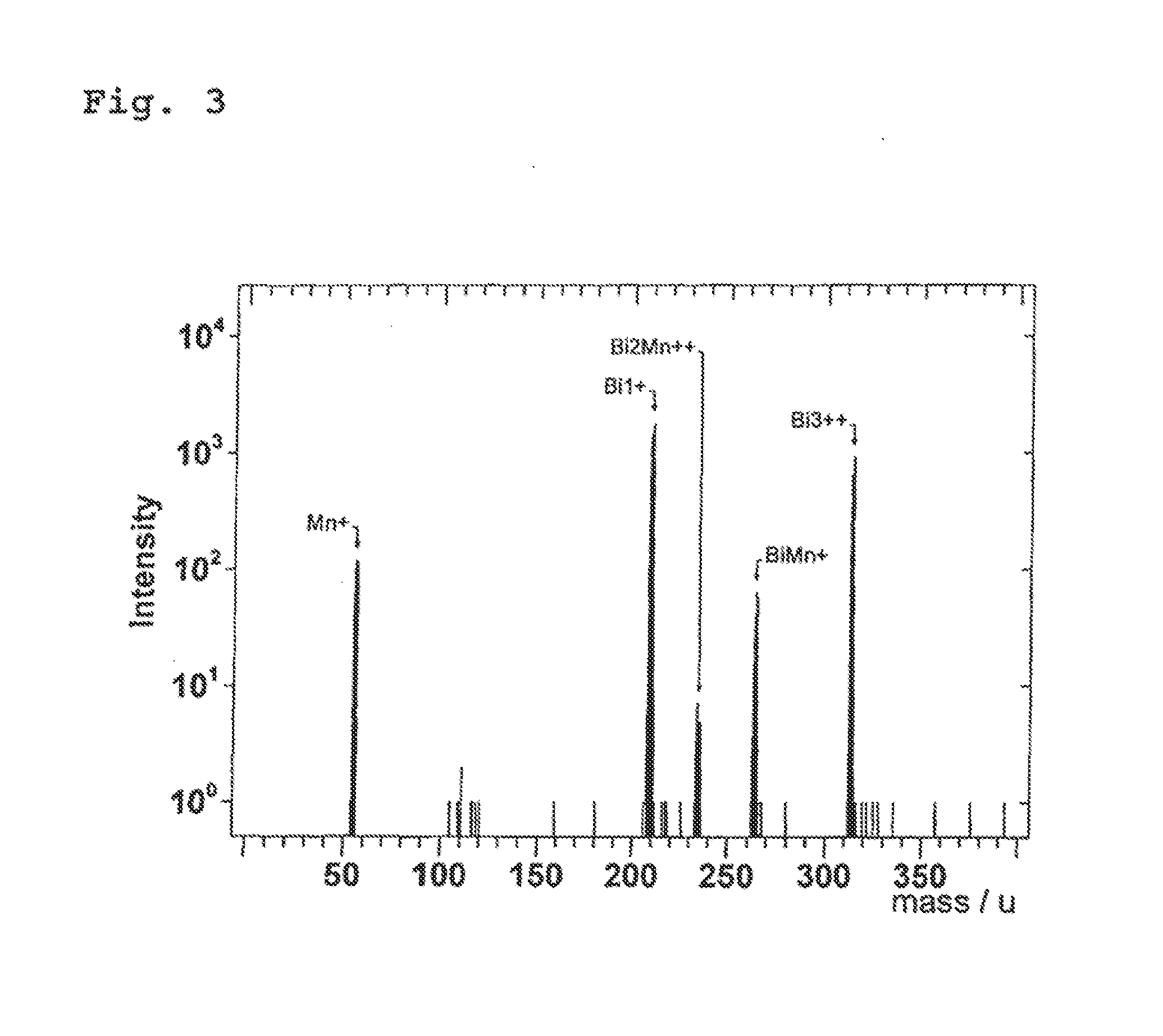

[0039]The preferred embodiments of the present invention will now be described with reference to FIGS. 1-4 of the drawings. Identical elements in the various figures are designated with the same reference numerals.

[0040]For implementation of the examples according to the invention, as are represented in FIGS. 3 and 4, a bismuth liquid metal ion cluster source which contained 95% bismuth and 5% manganese in the alloy was used.

[0041]According to the invention, it emerged that bismuth cluster sources are ideally suited because of the heavy and intensive clusters and the different charge states for varying the fragmentation in the spectrum of an S-SIMS method or a G-SIMS method. The maximum achievable variation in the fragmentation is however still too low when using a pure bismuth cluster source.

[0042]Therefore in the present examples, as light an alloy component as possible was added to the bismuth emitter, which alloy component emits atomic primary ions in the lower mass range of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

| atomic weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com