Energy-efficient and reliable operation of a vacuum waste collection system

a vacuum waste collection and reliable technology, applied in the field of waste management and waste disposal, can solve the problems of shutting down an entire branch line or transport line, affecting the efficiency of the system, so as to achieve energy-efficient and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]Throughout the drawings, the same reference characters will be used for corresponding or similar elements.

[0044]In order to avoid misconceptions, it should be understood that the term ‘waste’ not only includes what traditionally is denoted as ‘household waste’ or ‘household garbage’ but also includes all fractions within the field of waste disposal such as, but not limited to paper, clothes, laundry, packages and organic waste.

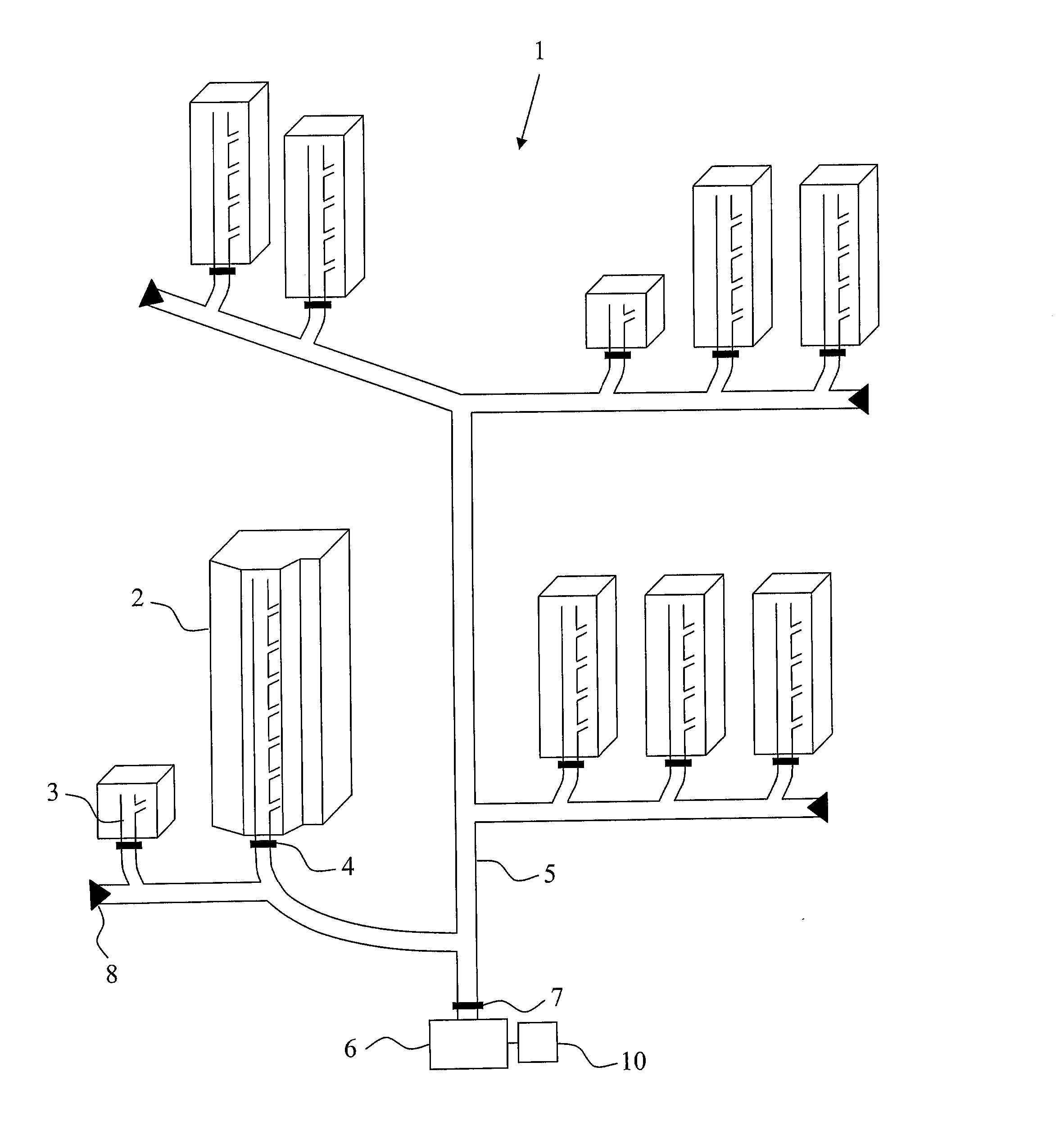

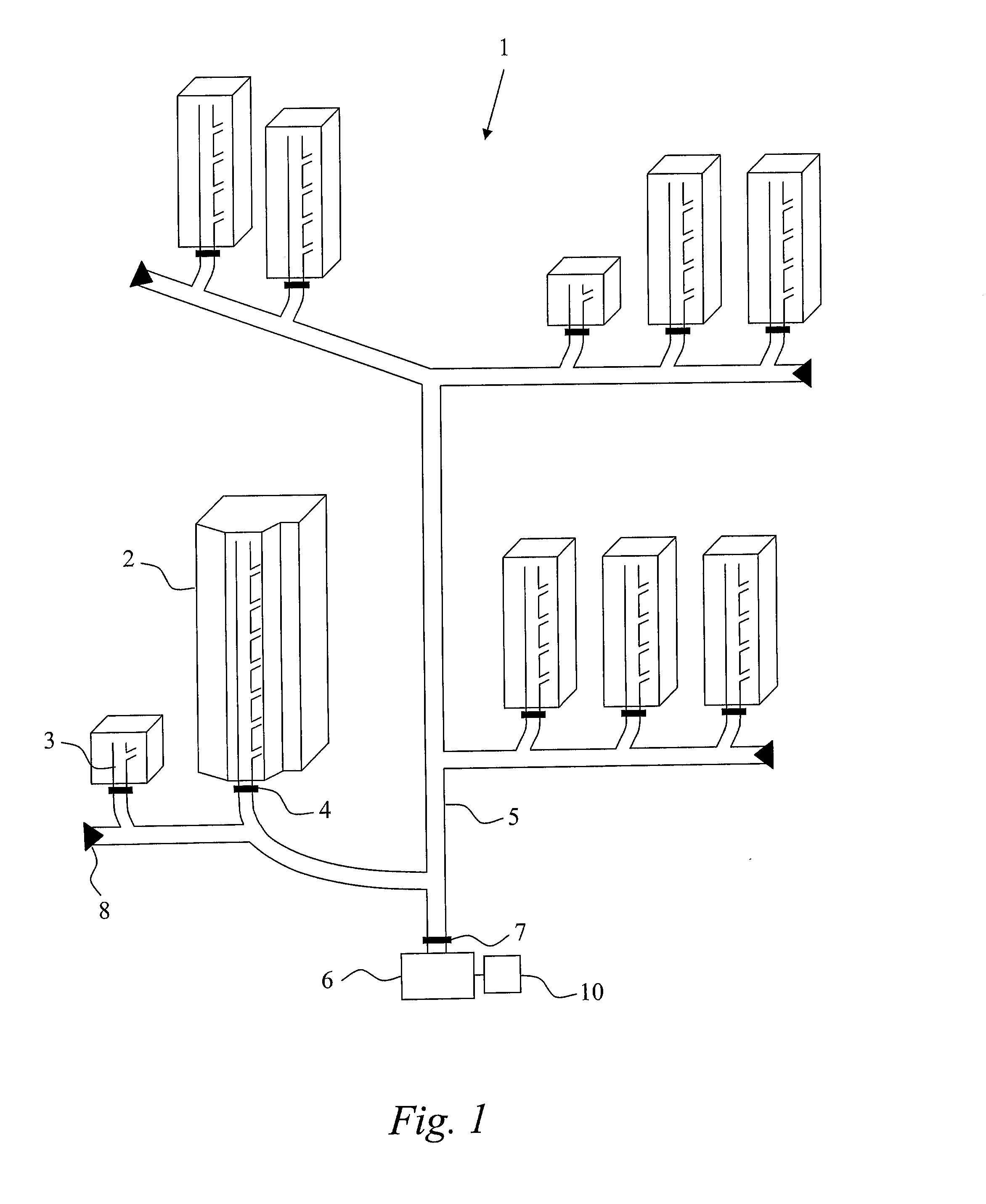

[0045]For a better understanding of the invention, a general overview of an example of a vacuum waste collection system will now be made with reference to FIG. 1.

Example System Overview

[0046]FIG. 1 is a schematic drawing illustrating an example of a vacuum waste collection system. As an example, assume that the vacuum waste collection system 1 is installed in a residential and / or business area having a number of buildings. Each building 2 is installed with a waste chute 3, or equivalent. In this particular example, the waste chutes are vertical chutes ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com