Rotary compressor with an installed circulation control unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

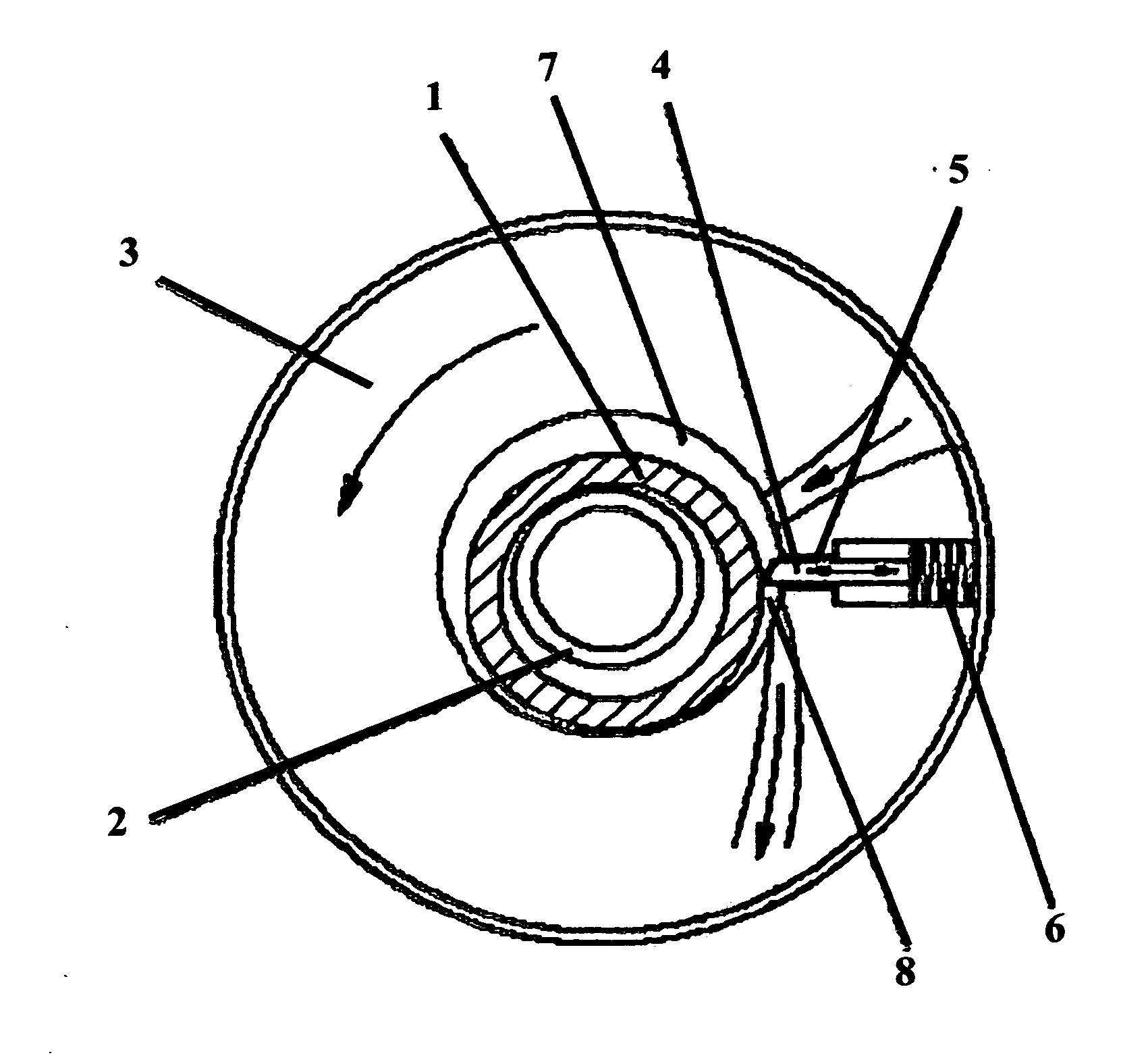

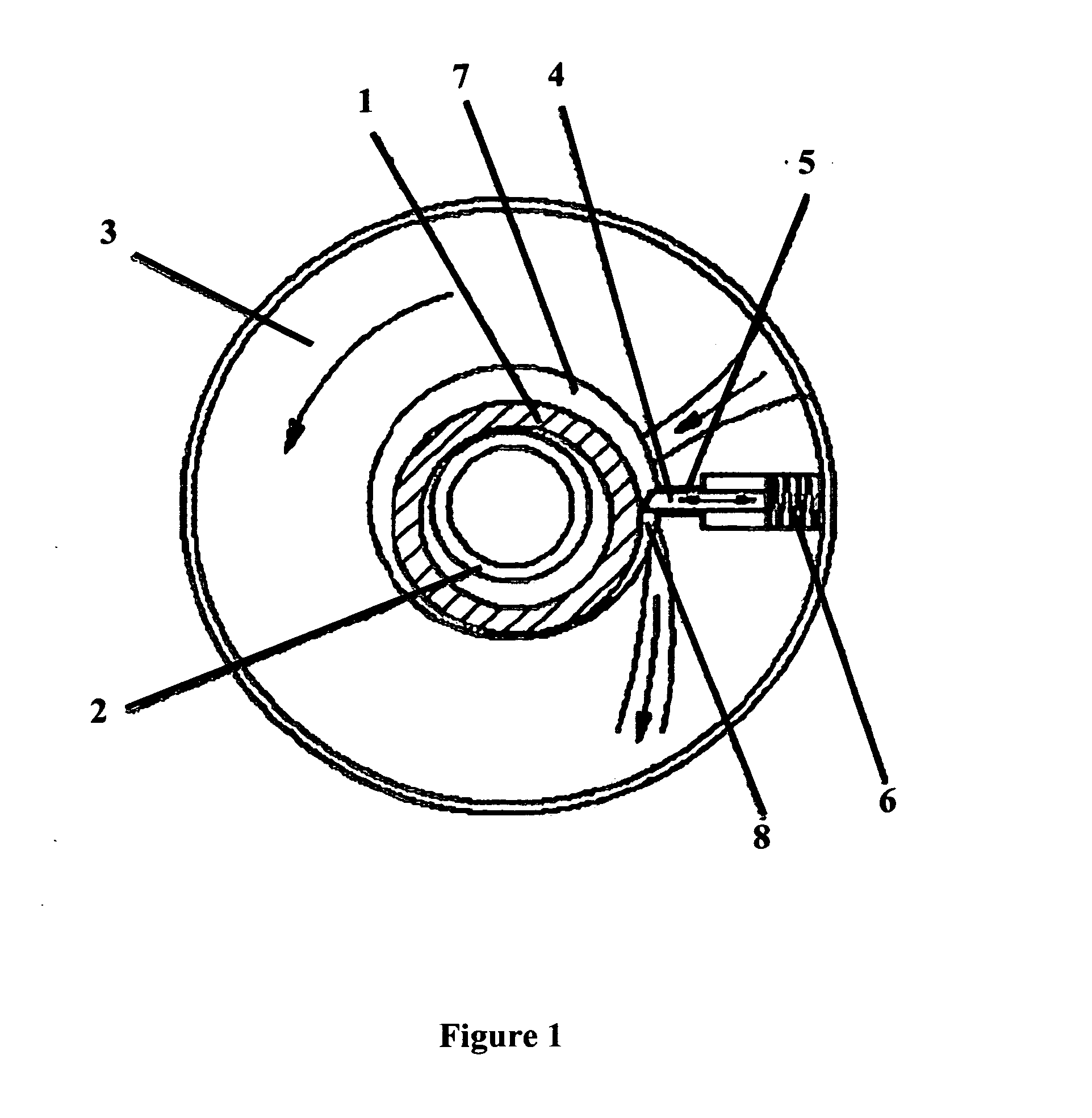

[0034]According to FIG. 5, the installation of the electromagnetic coil 10 onto the rotary compressor in the first embodiment to control the opening and closing of the vane 4 is further described as follows:

[0035]The rotary compressor (as shown in FIG. 1) is bored horizontally to make a hole that is at the same level of and perpendicular to the vane 4. This hole passes through a shield 17 and the cylinder block 3 of the rotary compressor until it reaches the slot 5 where the vane 4 is installed. The size of the hole is small enough for the armature core 15 to move back and forth fitly. Then, the vane 4 is pressed into the slot 5 entirely and an area where the bored hole intersects with the vane 4 is to be observed. A mortise is then formed on this particular area of the vane 4 (as shown in FIG. 7). Then, the electromagnetic coil 10 (as shown in FIG. 3) is installed at the bored hole and welded firmly at the joint of a flange 19 (Shape may differ according to the surface of the piece...

second embodiment

[0039]According to FIG. 9, the electromagnetic coil, which has the same structure and function as shown in FIG. 3 and FIG. 4, but the armature core 15 of which is shorter, and the shape of the flange 19 of which differs depending on the surface of the piece on which it is to be installed, is used for installation on the rotary compressor in the second embodiment to control the opening and closing of the vane 4.

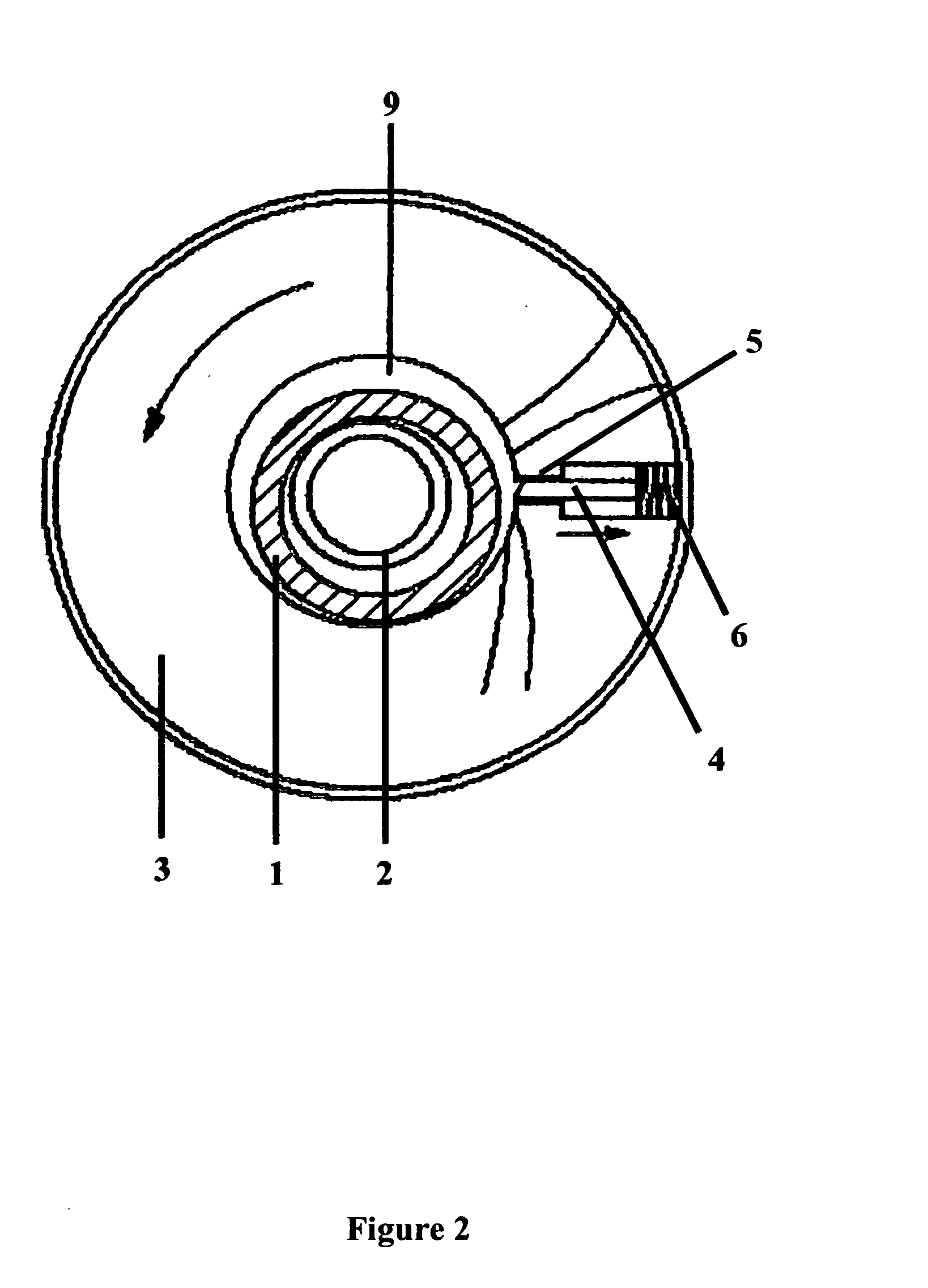

[0040]According to FIG. 10 and FIG. 11, a conventional rotary compressor is connected to a connection arm 20 from the vane 4. The size of the arm 20 must be at the right size to allow insertion through the spring 21 and past the shield 17 of the rotary compressor and it should be long enough to enable installation of the electromagnetic. A tube 22 is then used to cover the arm 20 inside of which a bushing 23 supports the arm 20 to provide stability and to ensure that the arm 20 is not detached from a bushing 23 at all times even when the vane 4 slides into the piston chamber 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com