Fast settling concentration tank for sewage in gangue

a concentration tank and sewage technology, applied in the direction of liquid displacement, waste water treatment from quaries, separation processes, etc., can solve the problems of large investment, inconvenient operation, occupying a lot of space, etc., and achieves no waste mine clean production, simple structure, and stable water quality. the effect of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]Embodiments of the present invention will now be described, by way of example only, with reference to the accompanying drawings.

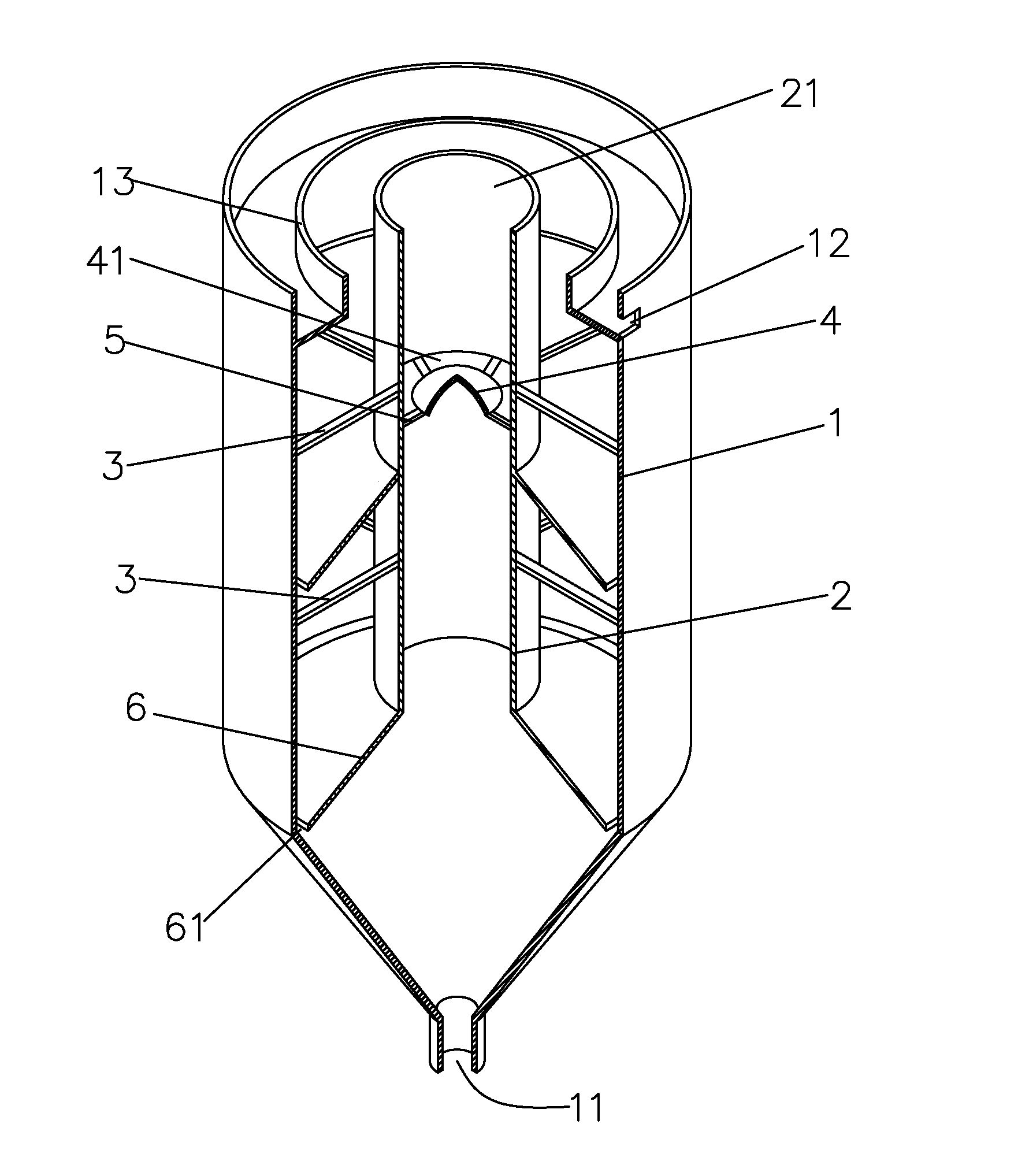

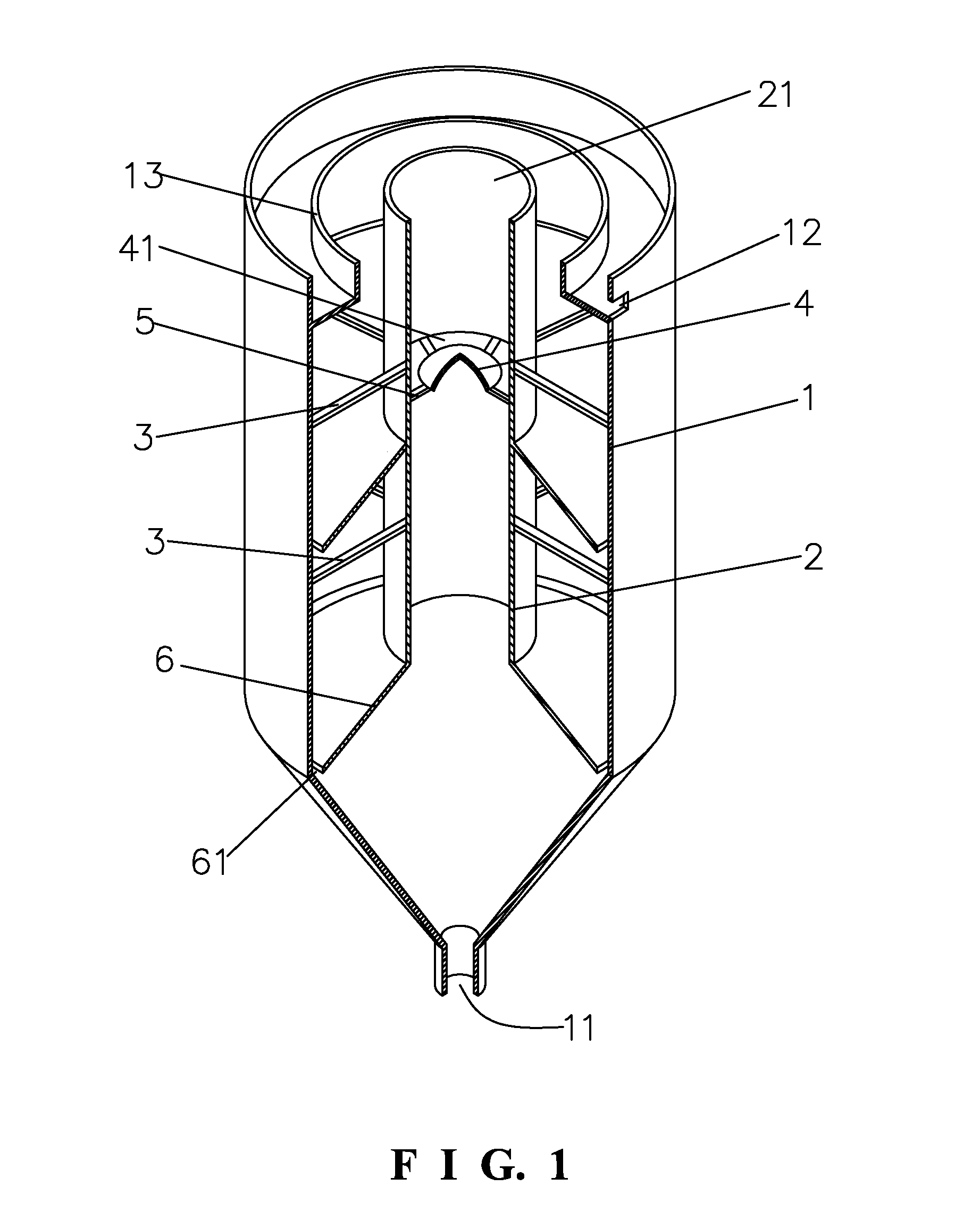

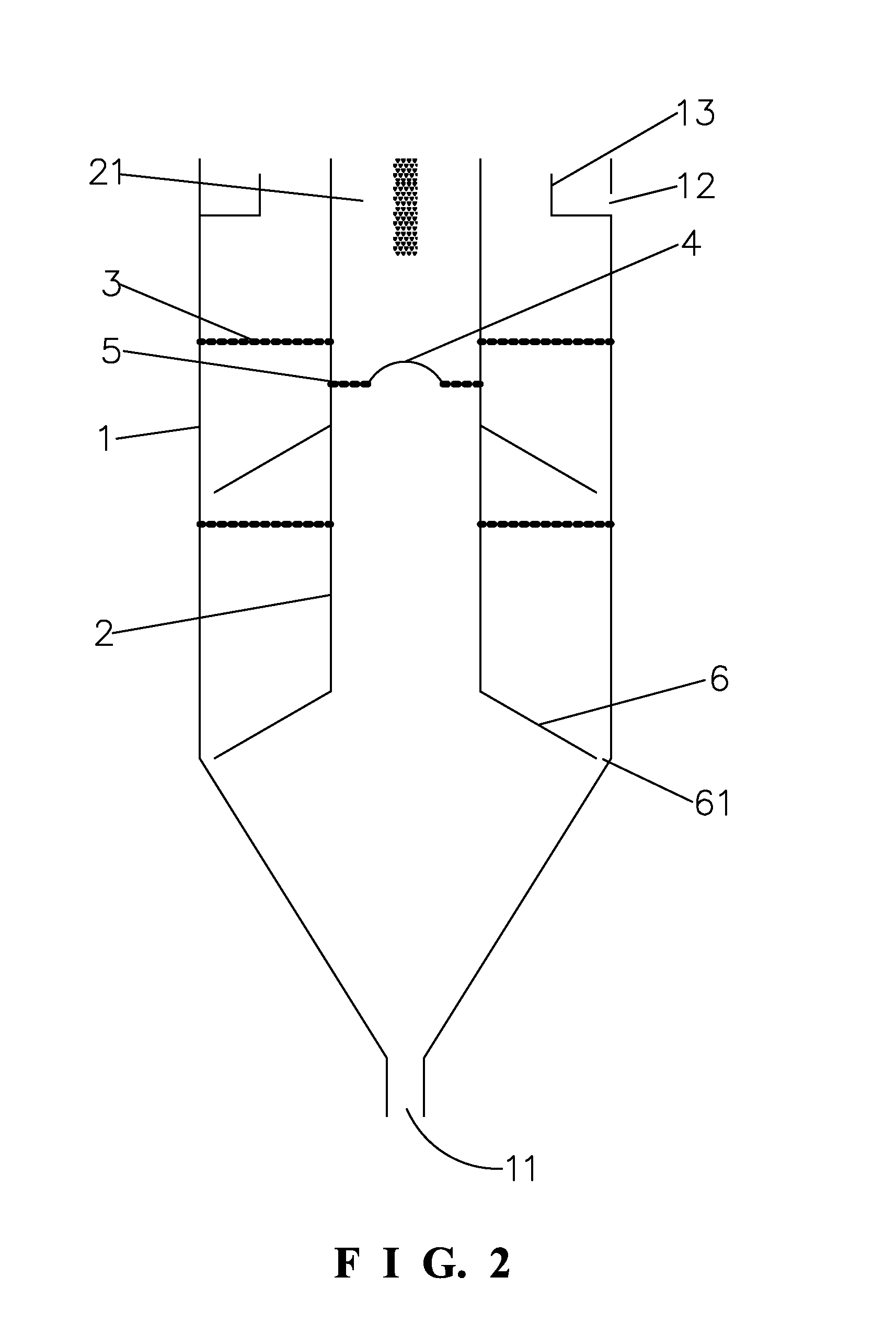

[0021]As shown in FIG. 1 to FIG. 4, the present invention disclosures a fast settling concentration tank for sewage in gangue. The fast settling concentration tank comprises an outer cylinder 1 and an inner cylinder 2 sleeved inside the outer cylinder 1 by a first bracket 3. The first bracket 3 is composed of a plurality of connecting rods to provide a support and retaining effect, which doesn't reduce the static clean water area to ensure the cleaning effect. The upper end of the inner cylinder 2 is a sewage inlet 21. A baffle plate 4 is provided in the middle of the inner cylinder 2 by a second bracket 5. A feeding gap 41 is formed between the edge of the baffle plate 4 and the inner wall of the inner cylinder 2. The second bracket 5 is composed of a plurality of connecting rods to provide a support and retaining effect, which doesn't reduce the pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com