Composite modular self actuating variable pitch marine propeller

a self-actuating, marine technology, applied in the direction of marine propulsion, rotors, vessel construction, etc., can solve the problems of difficult adjustment or keeping adjustment, high cost, and inability to have the best of both worlds for any given situation, etc., to achieve simple, durable and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

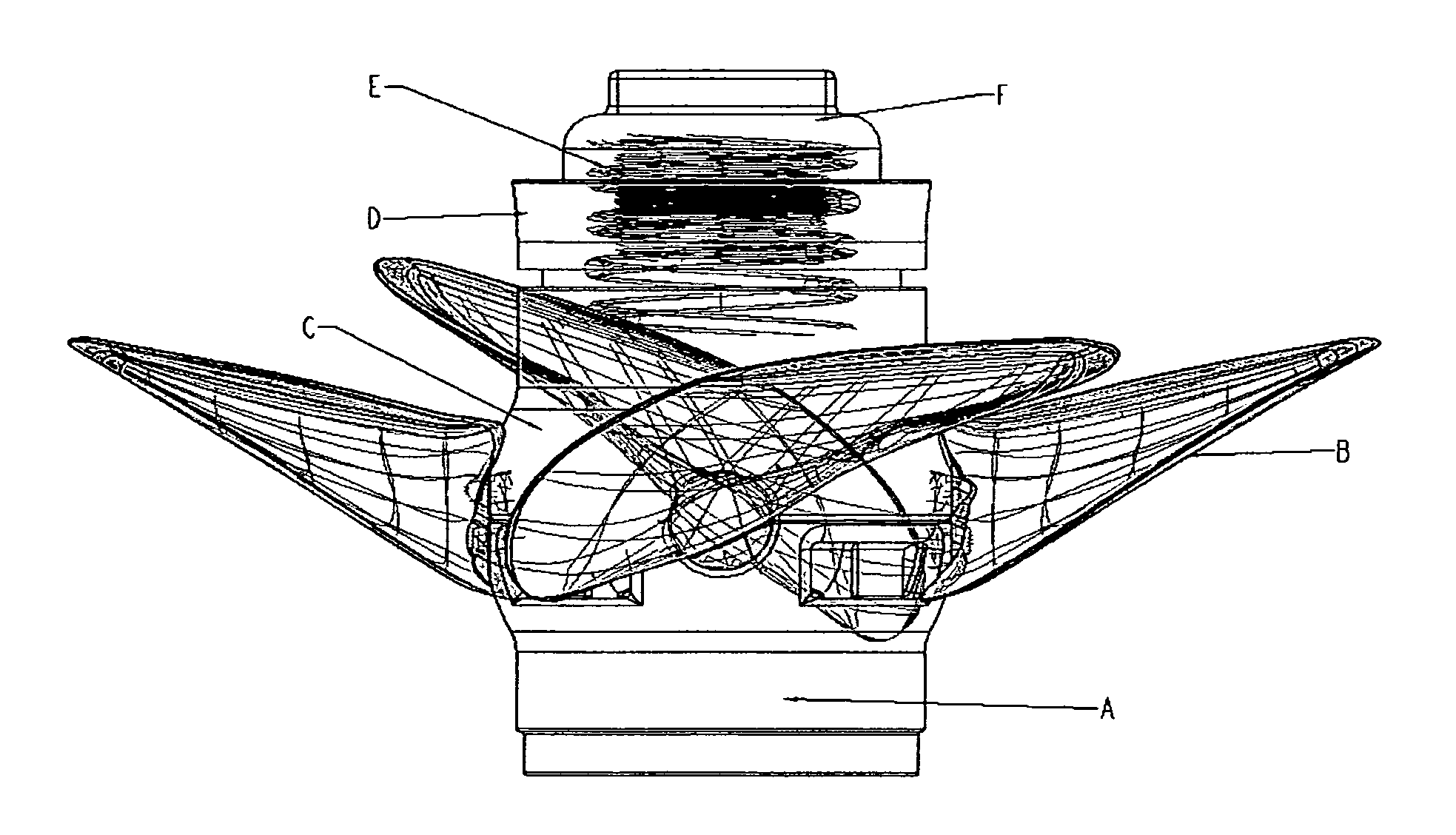

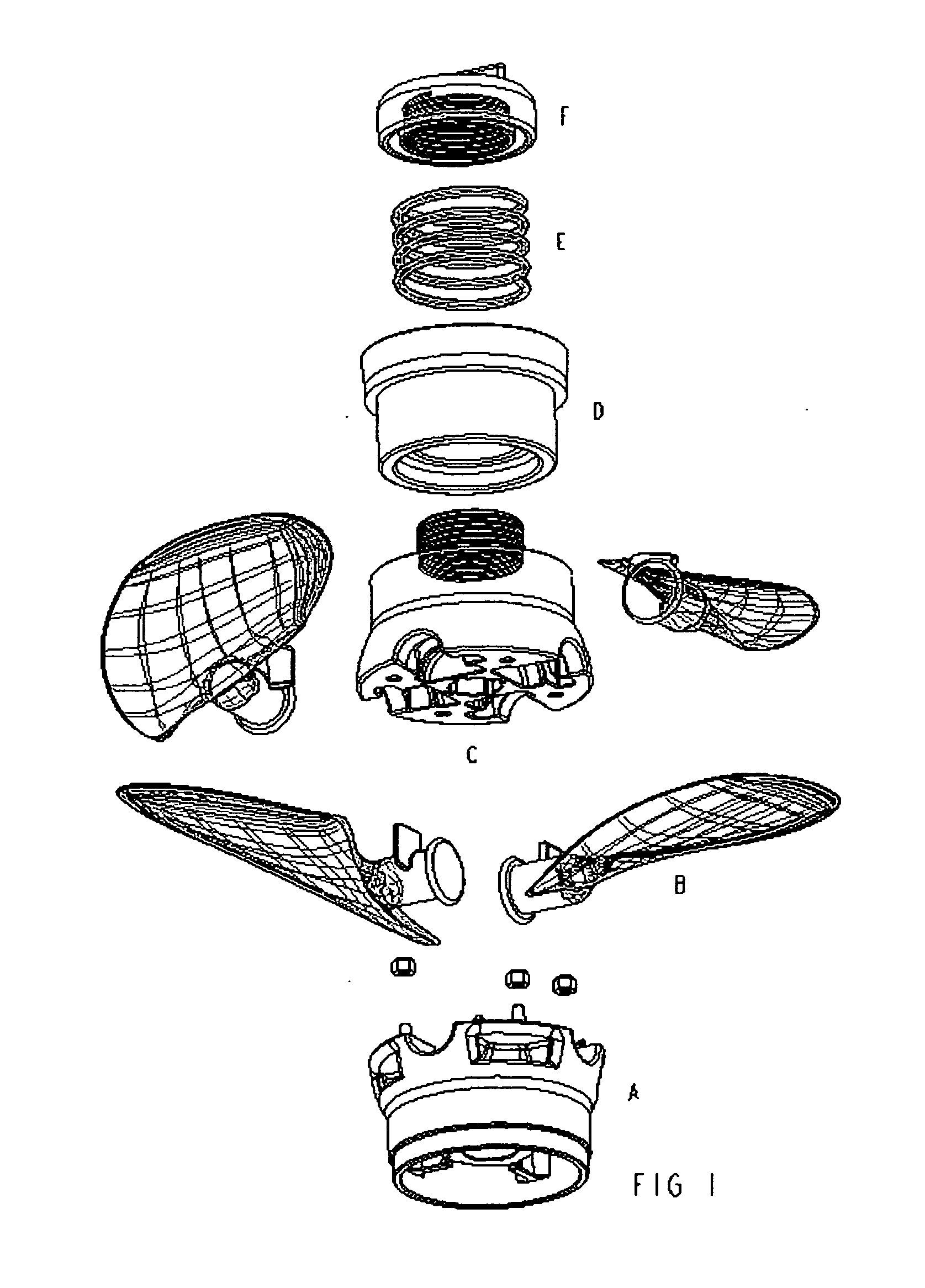

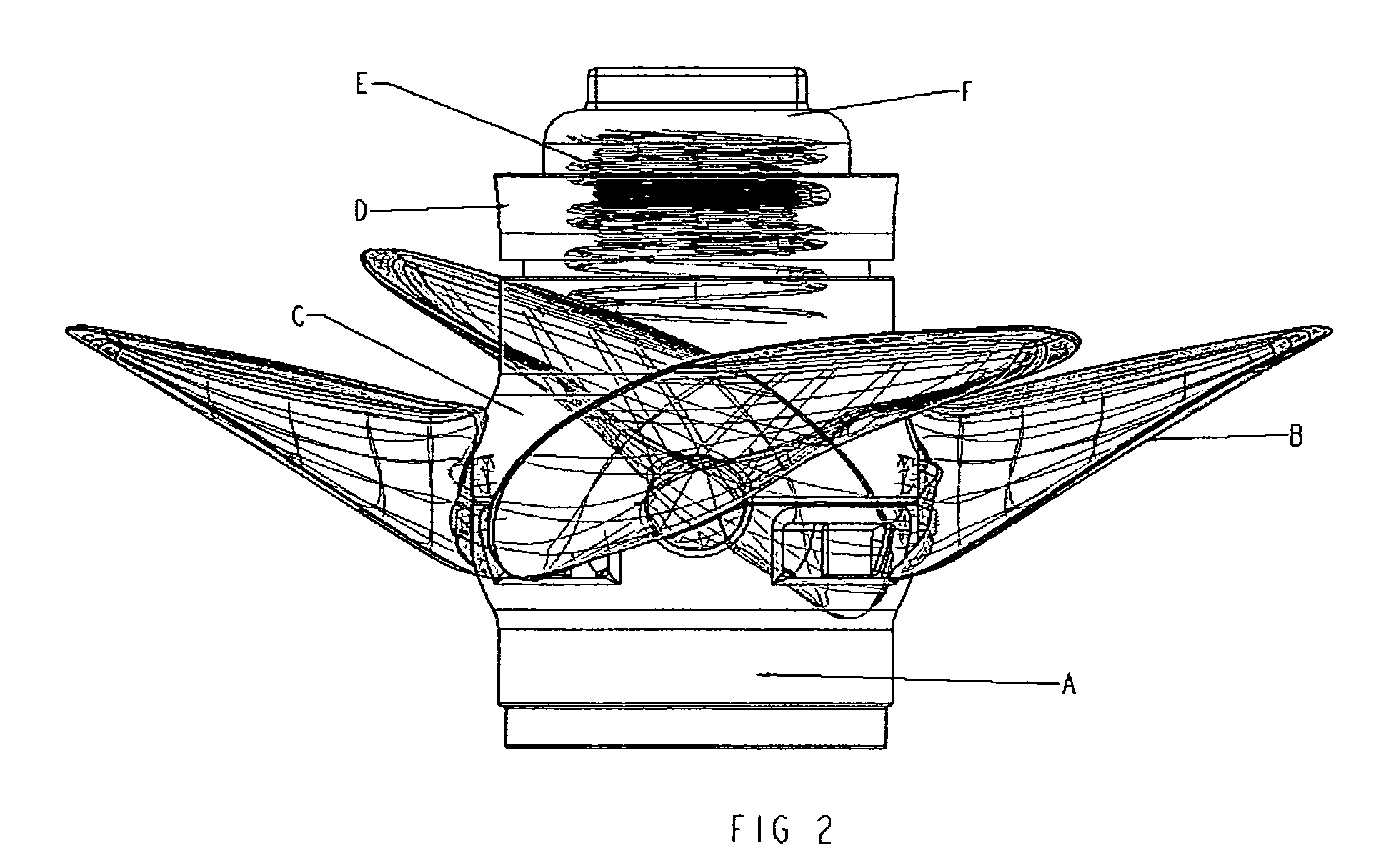

[0032]Now referring to the drawings, FIGS. 1-14, they show the propeller assembly of the present invention, which typically has bottom, middle and top hub sections that are coupled together, along with a top cap, a compression spring and four blades. The diameter of the entire propeller is typically 16 inches and is intended for engines with horsepower up to 300 horsepower and all parts with the exception of the spring, nuts and splined insert are made of a plastic known as VERTON, containing 30 percent long fiber filler.

[0033]With reference to FIG. 1, and by way of a brief overview, the propeller assembly includes a bottom hub section A, 4 unitary blade and root portions B, a middle hub section C, a top hub section D, a compression spring E and a top end cap F.

[0034]By way of assembly and in reference to FIG. 1, the four blades B, which are shown in FIG. 3, are represented by a main blade area, a blade shaft 2, large blade shaft end 3, a flat section of a transverse protrusion 4, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| forces | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com