Steel Sheet for Formed Member Having Enhanced Ductility, Formed Member, and Method for Manufacturing the Formed Member

a technology of formed members and enhanced ductility, which is applied in the direction of metal layered products, metal coating processes, thin material processing, etc., can solve the problems of limited increase in the strength of steel sheets for automobiles, increased costs and abrasion of cold forming dies, and difficulty in adjusting the shape of steel sheets, etc., to achieve high strength and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

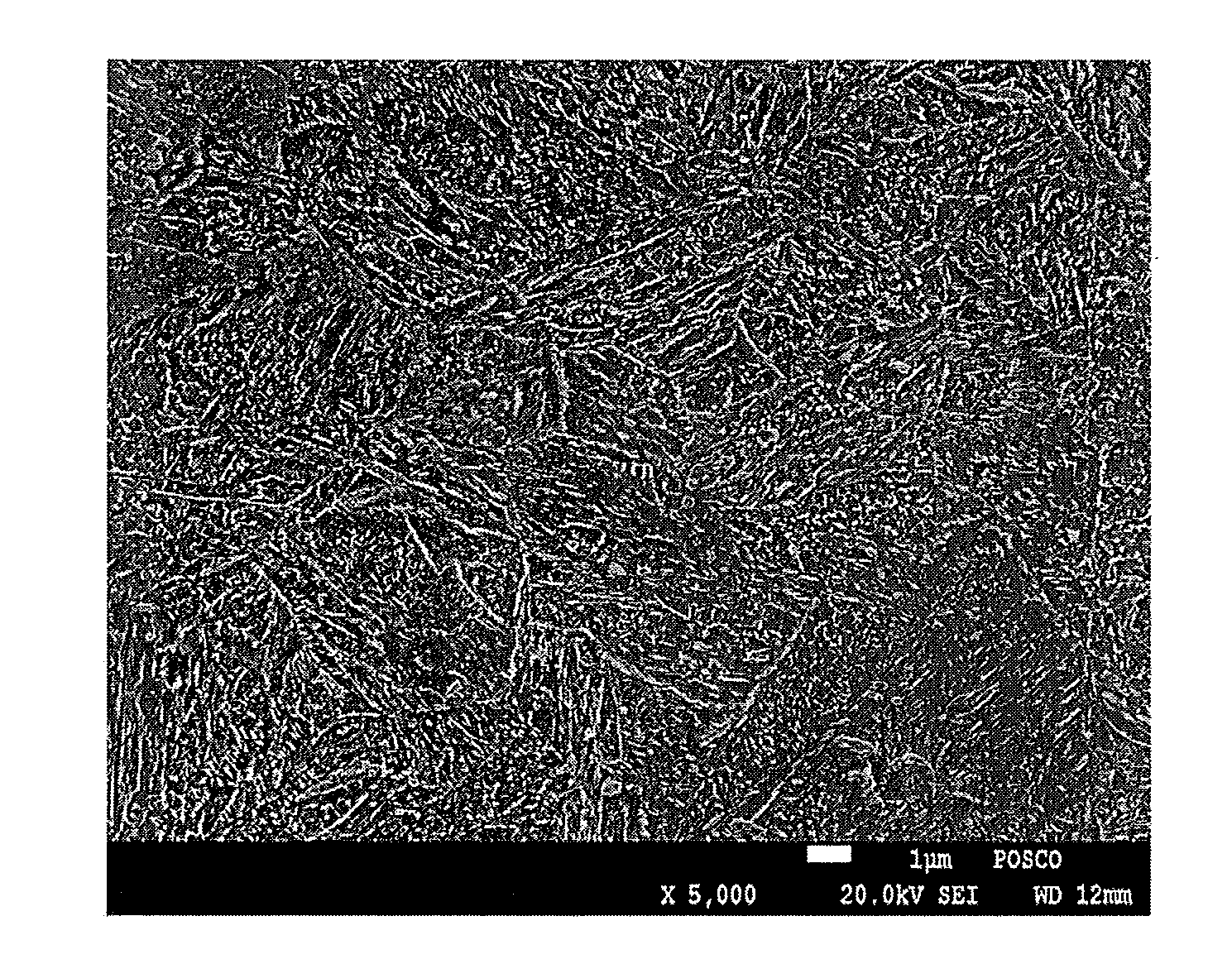

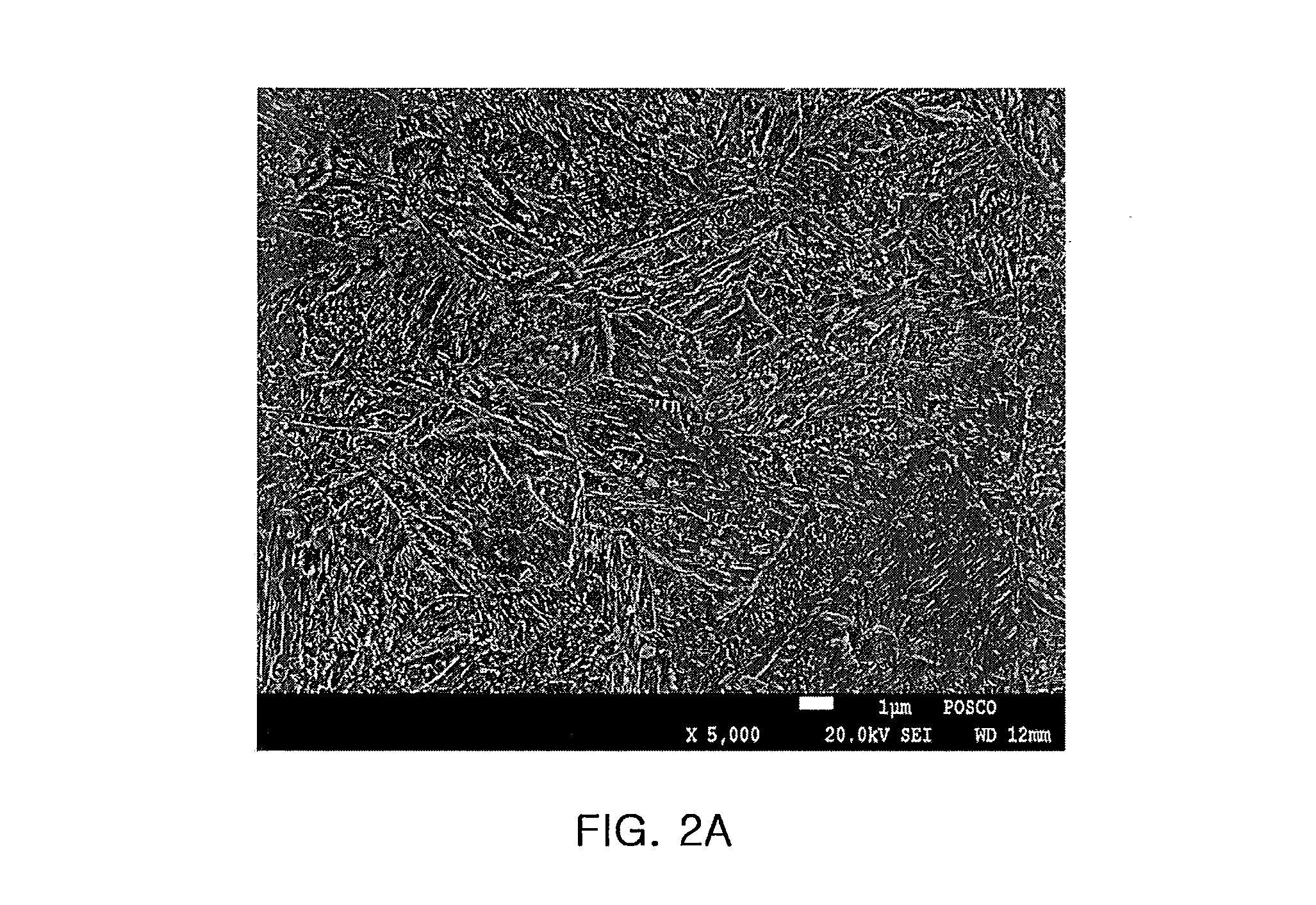

Image

Examples

example

[0063]Steel slabs having compositions as shown in table 1 and formed by vacuum melting were heated at 1000° C to 1300° C. for 1 hour in a heating furnace, and were hot-rolled to form hot-rolled steel sheets. The hot-rolled steel sheets were cooled at a predetermined temperature in a furnace. The hot rolling was finished at a temperature range of 850° C. to 950° C., and the cooling temperature at the furnace was 680° C. Thereafter, the hot-rolled steel sheets were pickled and cold-rolled at a reduction ratio of 50%. The cold-rolled steel sheets were annealed at 780° C. Thereafter, the cold-rolled steel sheets were finally continuously annealed at an overaging temperature of 400° C.

TABLE 1Chemical Composition (weight %)Nos.CSiMnPSAlNOthers*IS 10.111.63.030.00270.00530.0340.0033—IS 20.311.61.540.00230.00380.0320.0022—IS 30.311.63.030.00250.00430.0390.0153—IS 40.321.63.000.00290.00540.0320.0037—IS 50.311.72.980.00350.00450.5650.0027—IS 60.311.11.540.01600.00710.0130.0039—IS 70.311.72.97...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com