Hydraulic control system having accumulator

a technology of hydraulic control system and accumulator, which is applied in the direction of positive displacement liquid engine, pump, machine/engine, etc., can solve the problems of hydraulic fluid not being delivered to the lubrication spot through the regulator valve, loss of hydraulic pressure, etc., to achieve the effect of reducing power loss, increasing flow volume, and simplifying the structure of hydraulic control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

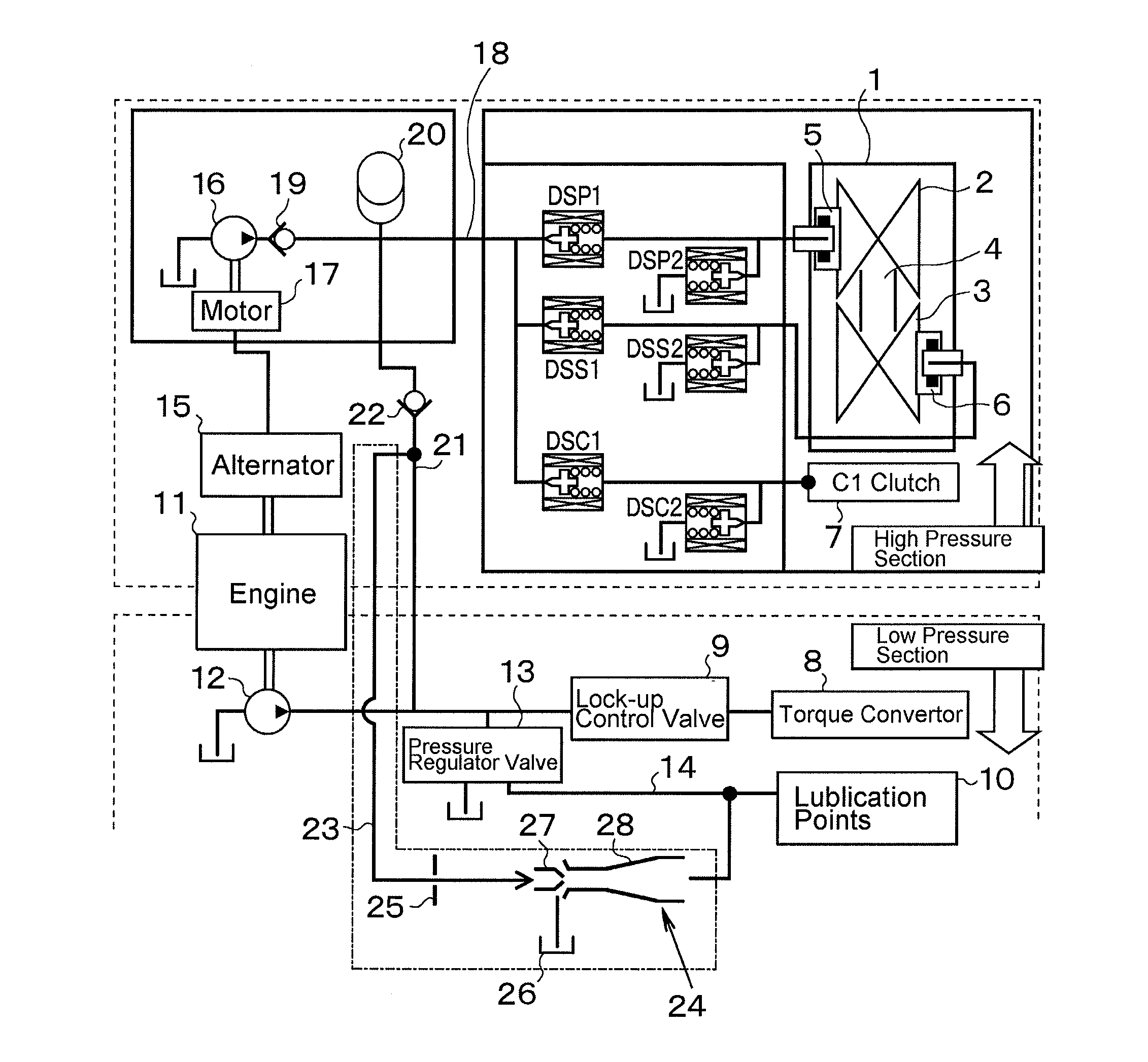

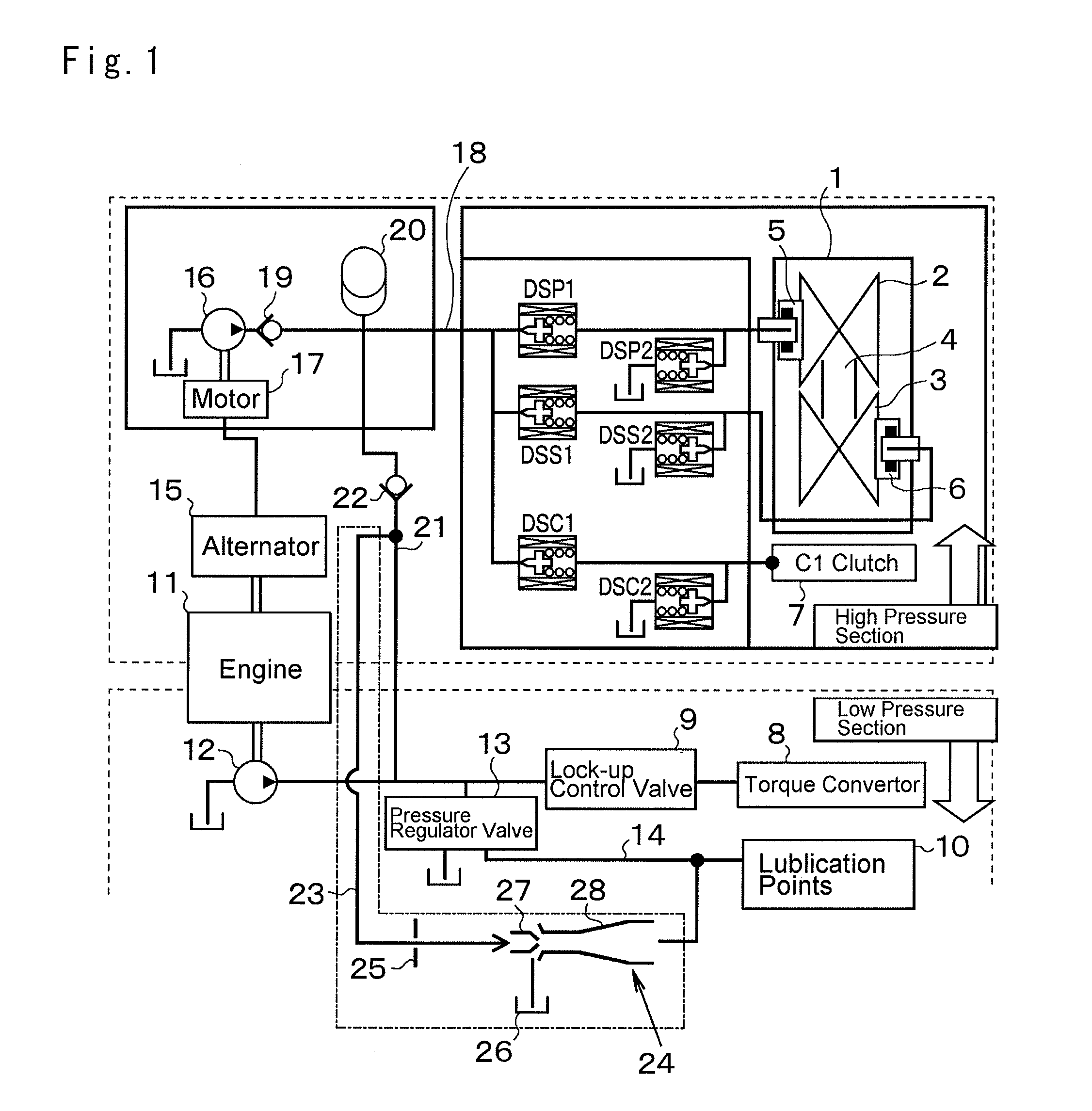

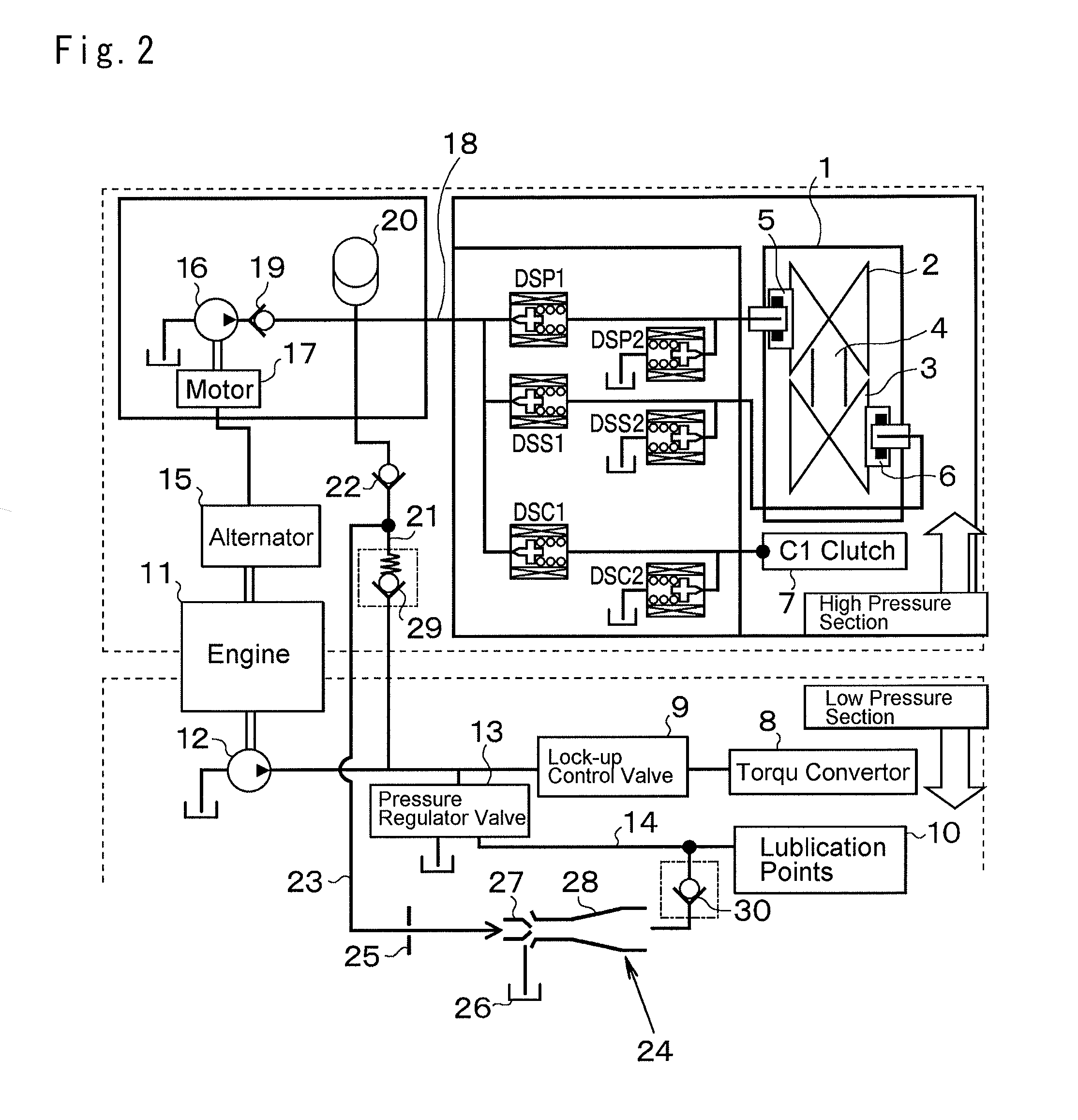

[0035]Referring now to FIG. 1, there is shown an example of applying the hydraulic control system of the invention to a continuously variable transmission used in an automobile. The continuously variable transmission 1 is a conventional belt-driven CVT comprising a drive pulley 2, a driven pulley 3 and a belt 4 mounted driveably on those pulleys 2 and 3 to transmit a torque therebetween. Each pulley 2 and 3 comprises a fixed sheave and a movable sheave being adapted for movement toward and away from the fixed sheave, and inwardly facing conical faces of the sheaves form a V-groove for holding the belt 4 therebetween. In order to move the movable sheaves axially, the pulleys 2, 3 are provided individually with hydraulic actuators 5, 6. In this preferred example, the movable sheave of the driven pulley 3 is moved axially in response to the application of pressurized hydraulic fluid to the actuator 6 thereby establishing a clamping pressure for clamping the belt 4 by the driven pulley ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com