Apparatus for electrolyzing sulfuric acid and method for electrolyzing sulfuric acid

a technology of electrolyzing apparatus and sulfuric acid, which is applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of increasing the transportation cost of chemical products compared with concentrated sulfuric acid, requiring a large amount of equipment cost, so as to achieve safe and high current efficiency , the effect of high current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

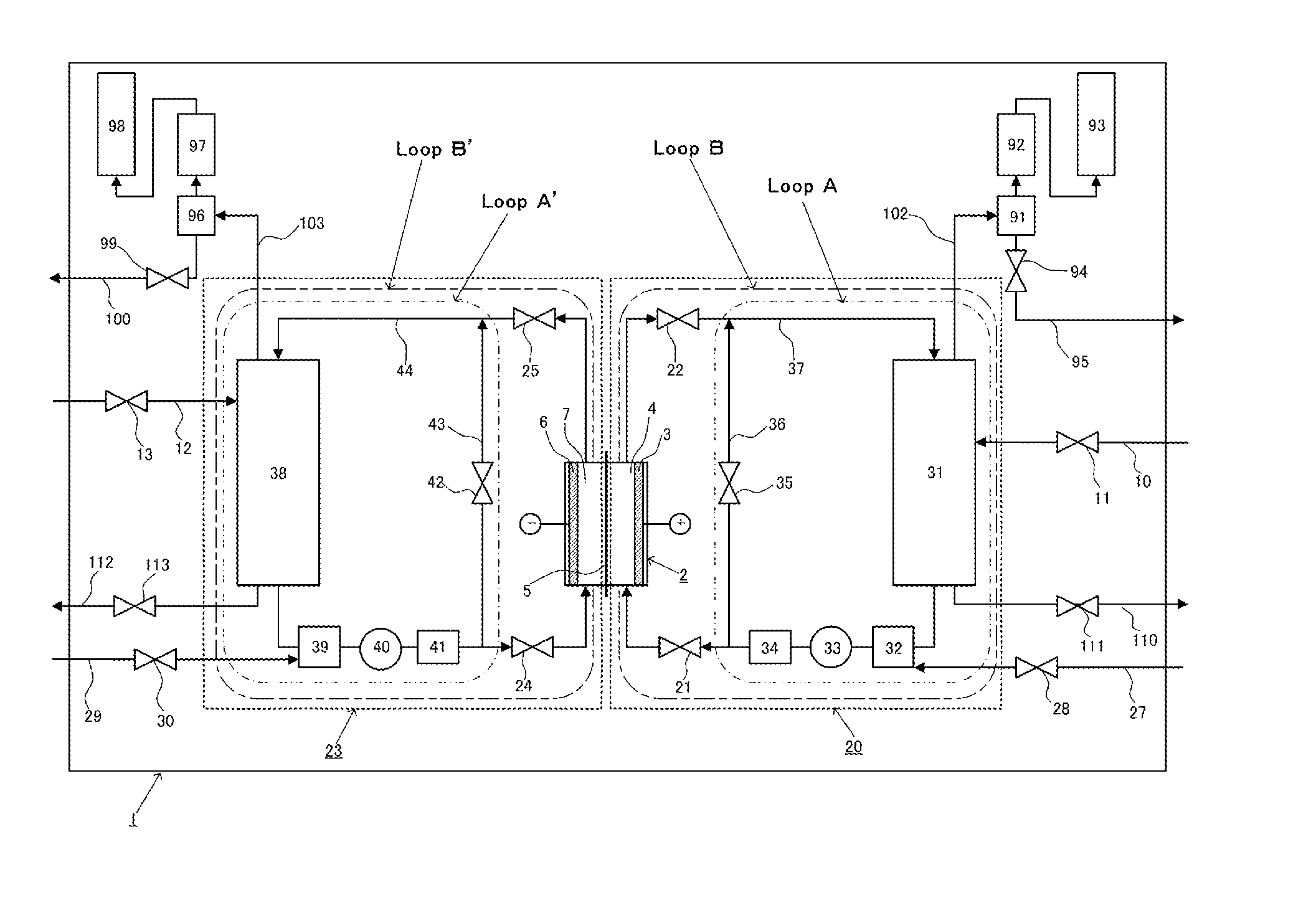

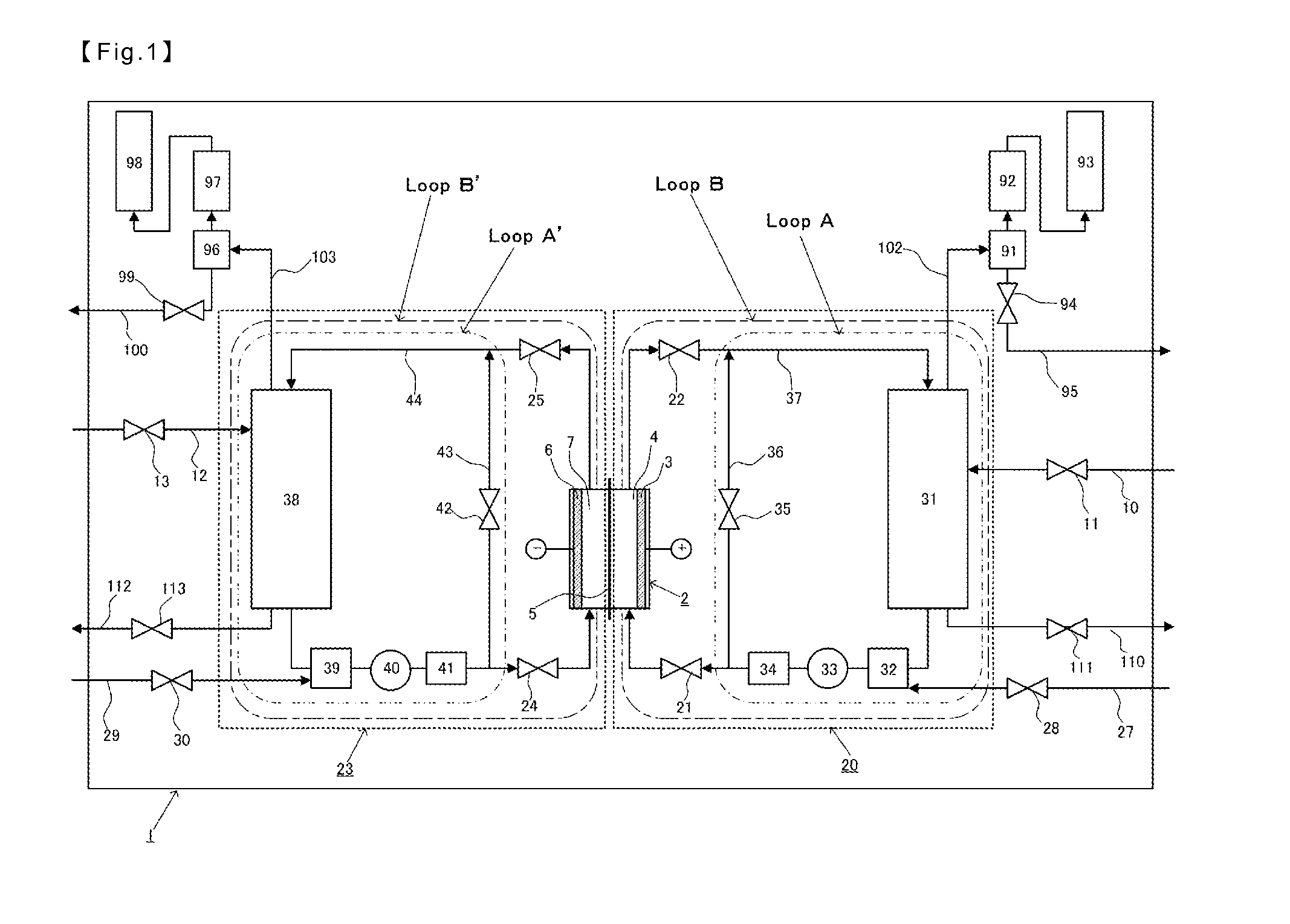

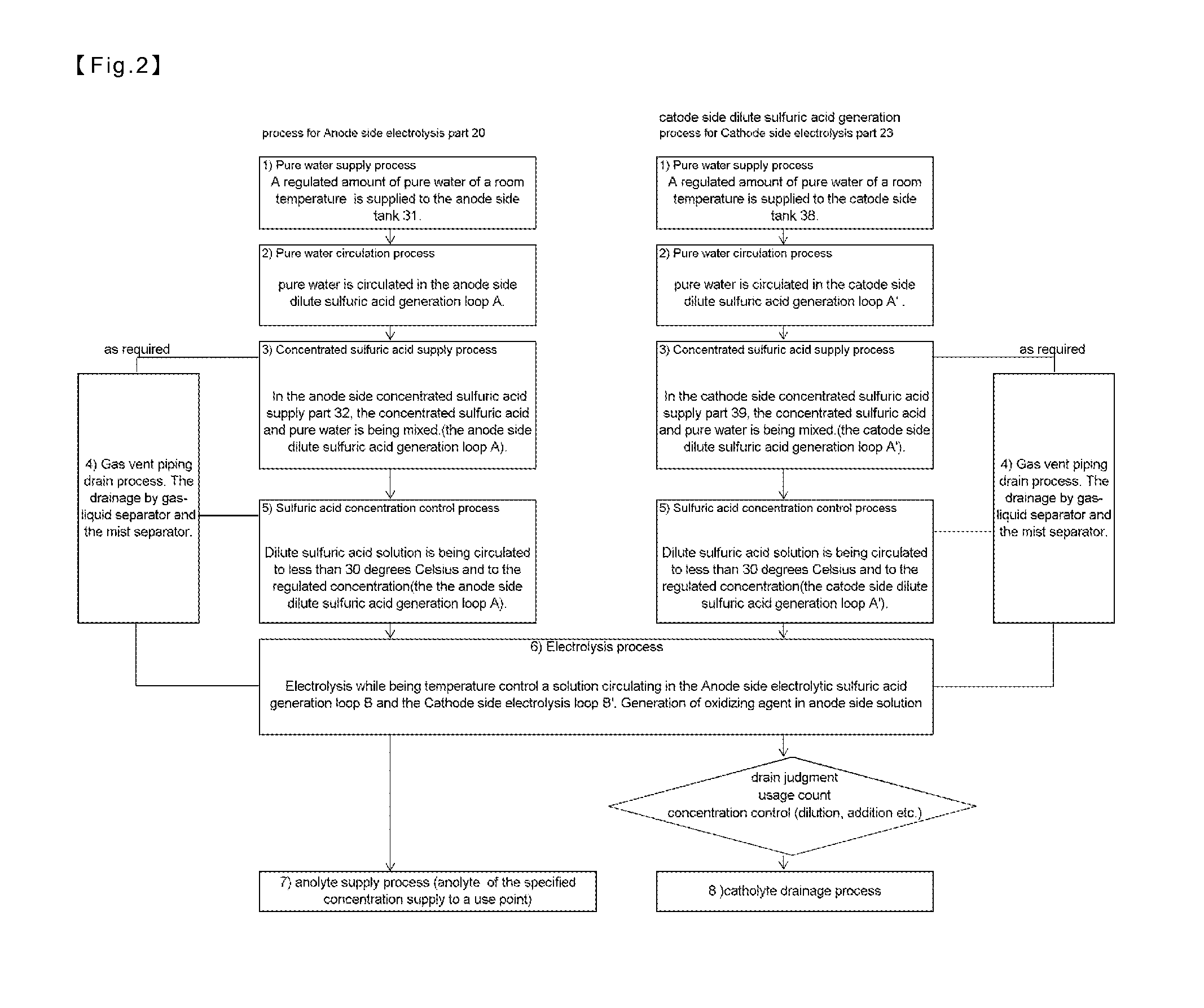

[0146]The experiment was conducted using the apparatus for electrolyzing sulfuric acid and the method for electrolyzing sulfuric acid shown in FIG. 1 and FIG. 2. For the anode 3 and the cathode 6 incorporated in the electrolytic cell 2, a conductive diamond electrode was applied, which was prepared in such a way that diamond provided with conductivity by boron doping was coated on a 200 mm φ silicon substrate. Current density was 100 A / dm2. For both the anode side and the cathode side, the sulfuric acid temperature and concentration control process was as follows, in which concentrated sulfuric acid was diluted with pure water to prepare dilute sulfuric acid of the specified temperature and the specified concentration.

[0147]The procedures for the anode side were as follows.

[0148]1) Pure water was supplied from the anode side pure water supply pipe 10 to the anode side tank 31 and stored. Feed amount of the pure water was weighed by using an ultrasonic integrating flow meter, which i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Dissociation constant | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com