Method for manufacturing wind turbine blades, blades for propellors, wings, or similar structures, and structure in the form of a blade obtained by means of this procedure

a technology of propeller blades and wind turbines, which is applied in the manufacture of final products, machines/engines, and other domestic objects, can solve the problems of compromising the mechanical performance of the blade, complicated manufacturing system, and increased cost, and achieves the effect of speed regulation and thermal control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]In the light of the above-mentioned figures and in accordance with the numbering adopted, we may observe in them a specimen preferred embodiment of the invention, which comprises the parts and elements that are described in detail hereinunder.

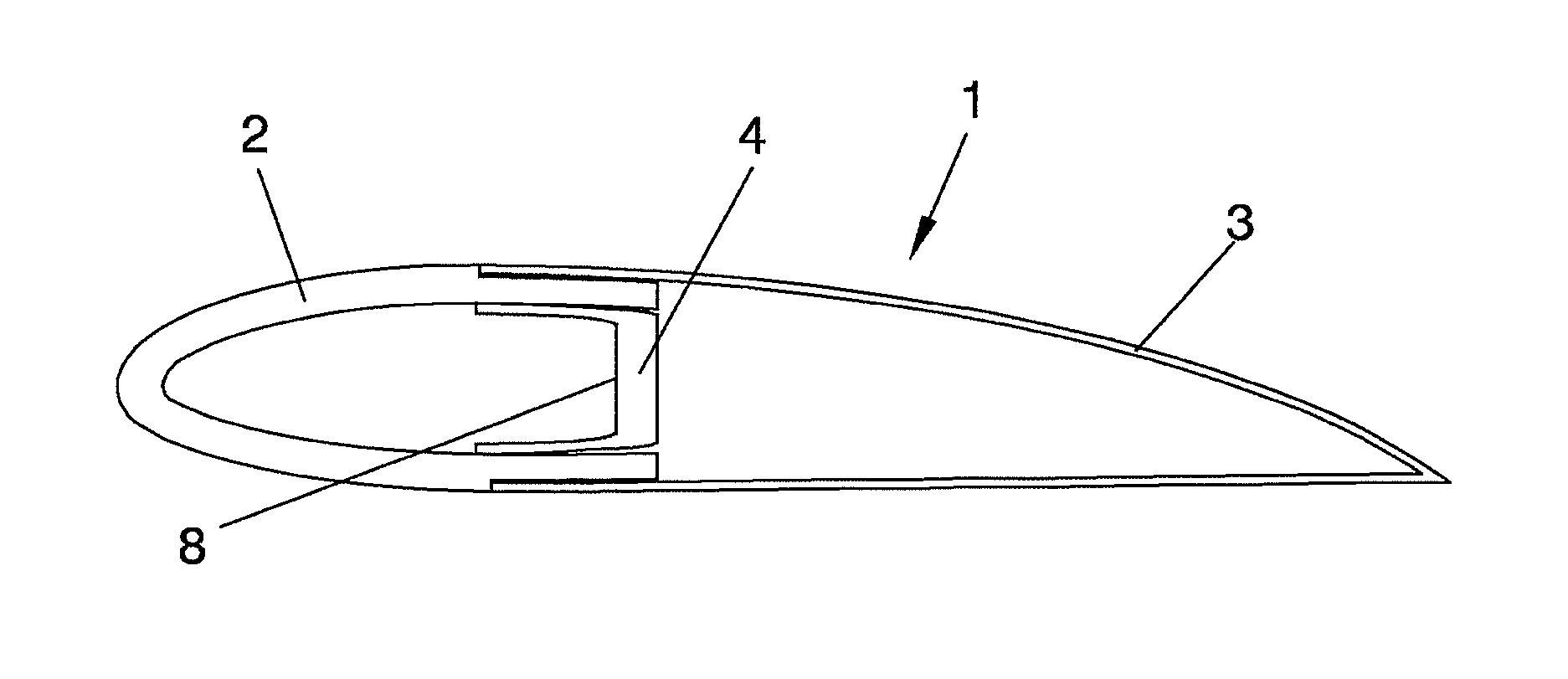

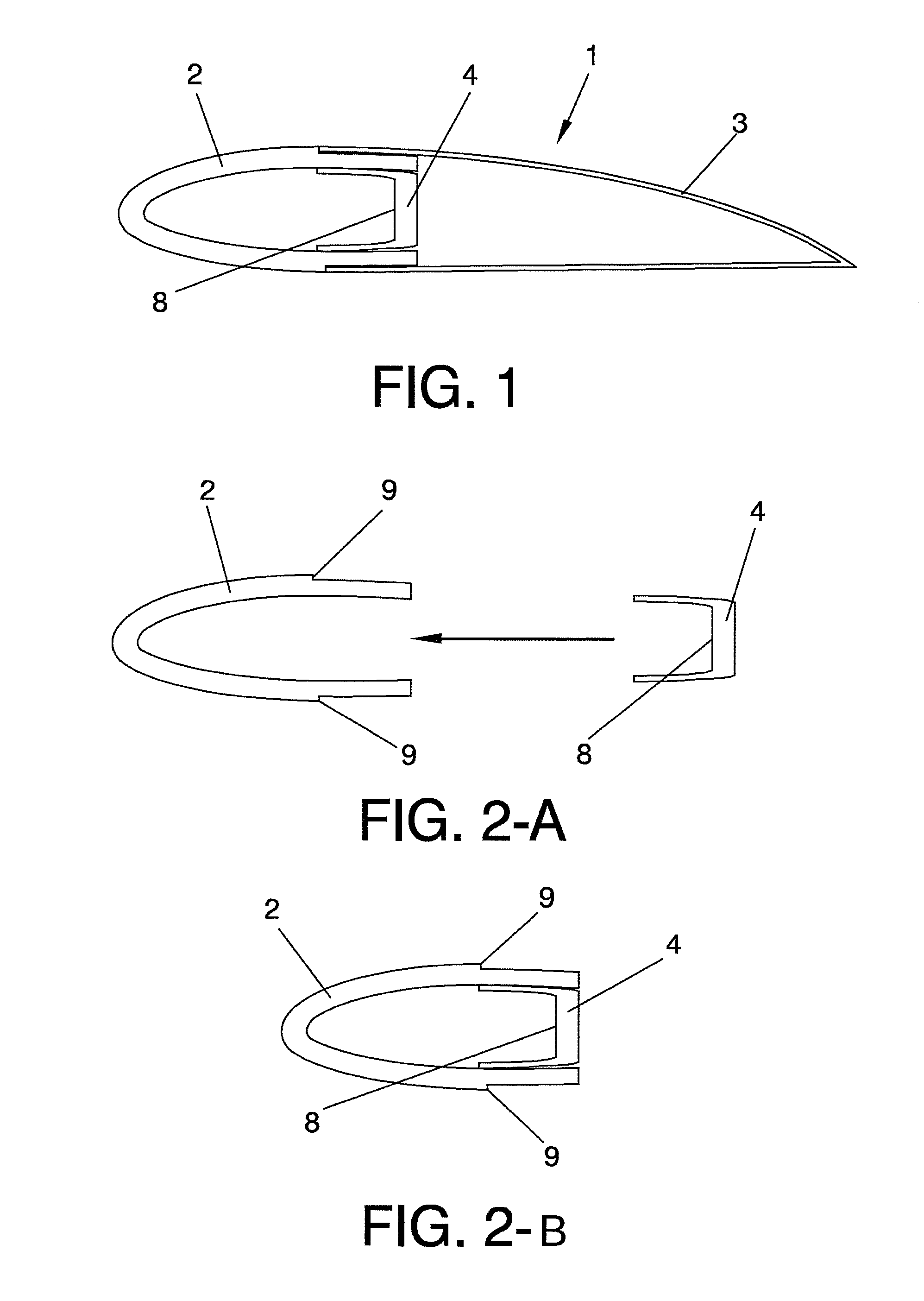

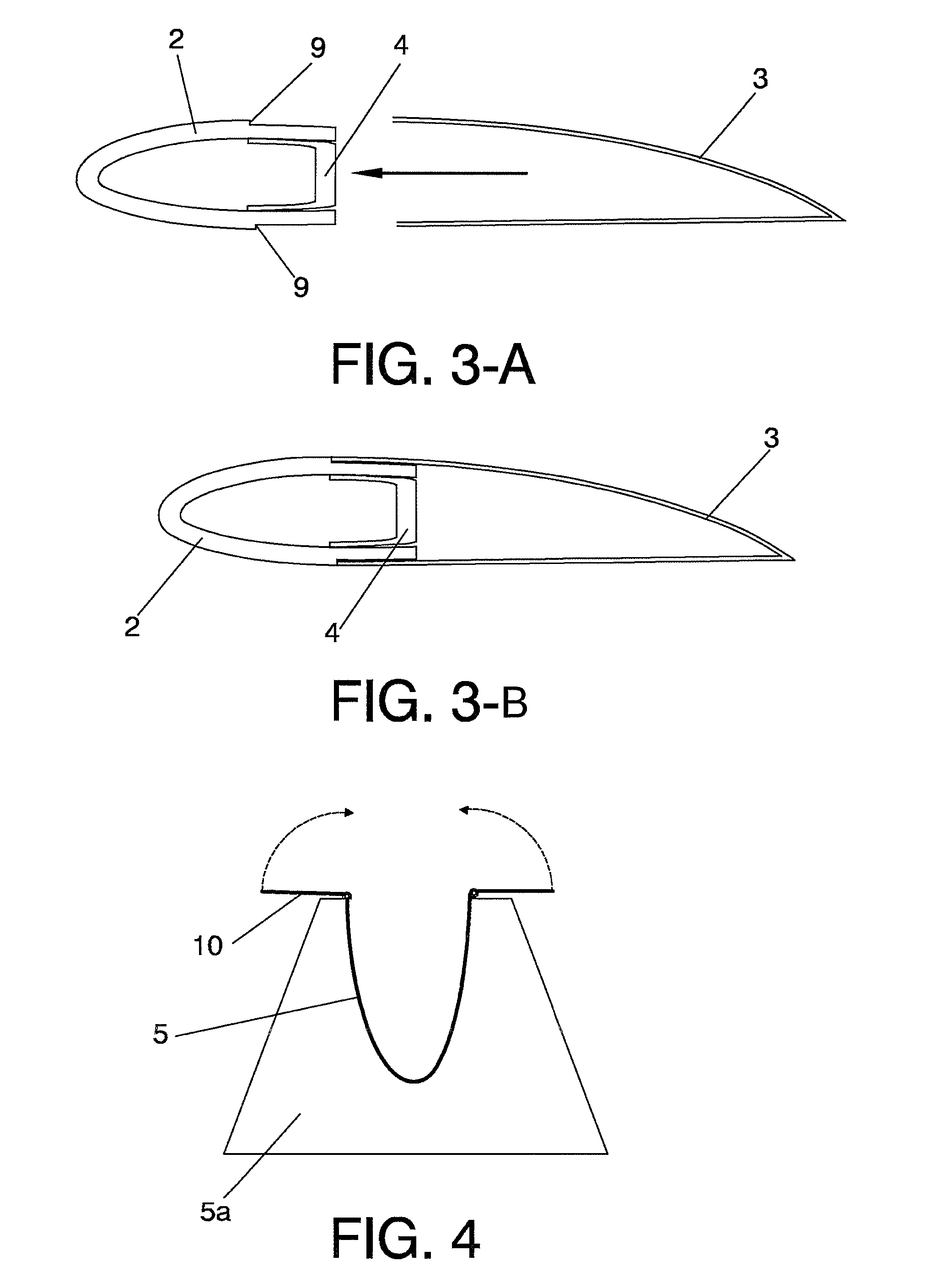

[0035]Considering said figures, we may observe that the procedure advocated is intended for the manufacture of a blade-like structure (1), which will be composed of a leading edge (2), a trailing edge (3) and, at least, one inner reinforcing side member (4) made up of pieces executed from sheets of prepreg material.

[0036]To this end, said procedure comprises the use of a female mould of the leading edge (5) and a female mould of the trailing edge (6), as well as a third mould (7) whereby a male jig (8) is obtained that acts as a lost mould for manufacturing the structural side member (4) and which may be C- or closed-box or even double-T shaped, said male jig (8) being made from composite.

[0037]The inner sides of the afore-mentioned femal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com