Flexible heat and moisture transfer system

a technology of heat and moisture transfer and flexible heat, which is applied in indirect heat exchangers, lighting and heating apparatuses, heating types, etc., can solve the problems of loss of heat energy, corresponding reduction in heating or cooling efficiency of the system, and inability to perform moisture exchang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

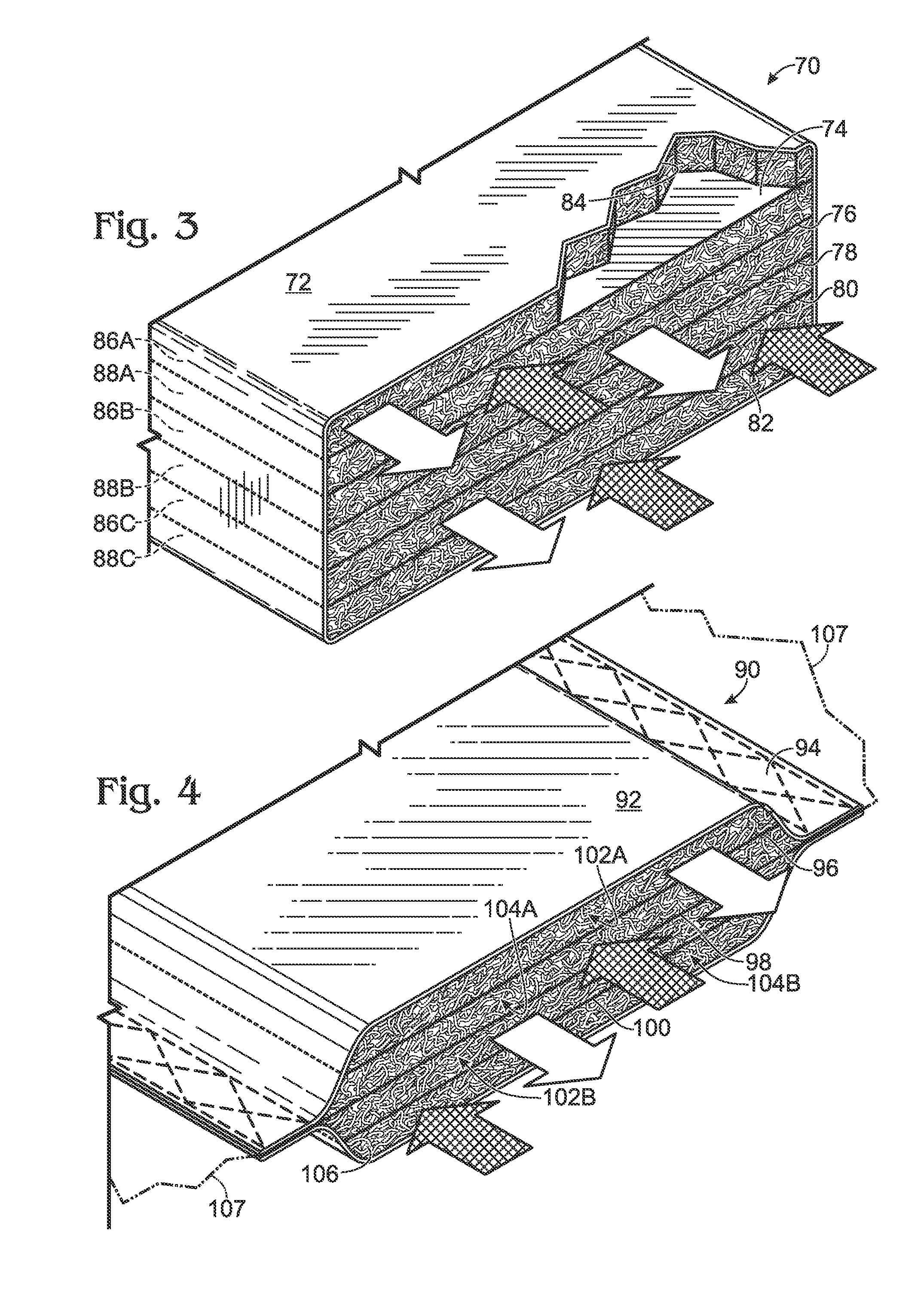

[0018]An efficient heat and moisture exchange apparatus is described herein which will not contaminate make-up air, and which has excellent heat exchange efficiency, high moisture exchange capability, and serves as a barrier to air flow between exhaust and makeup air streams. Furthermore, the exchanger described in the present disclosure is suitable for use with lightweight temporary, portable, and permanent structures in which the mechanical conditioning and ventilation equipment may not be located within or atop the structure but may instead stand on the ground adjacent the structure. In many of these cases, the structures may be pliable and flexible to enable packing and transport, such as tents, that are not amenable to large-scale rigid elements. Accordingly, a flexible heat and moisture exchanger is described that can be used in the operation of these flexible, mobile structures but can also be packed and transported easily with them.

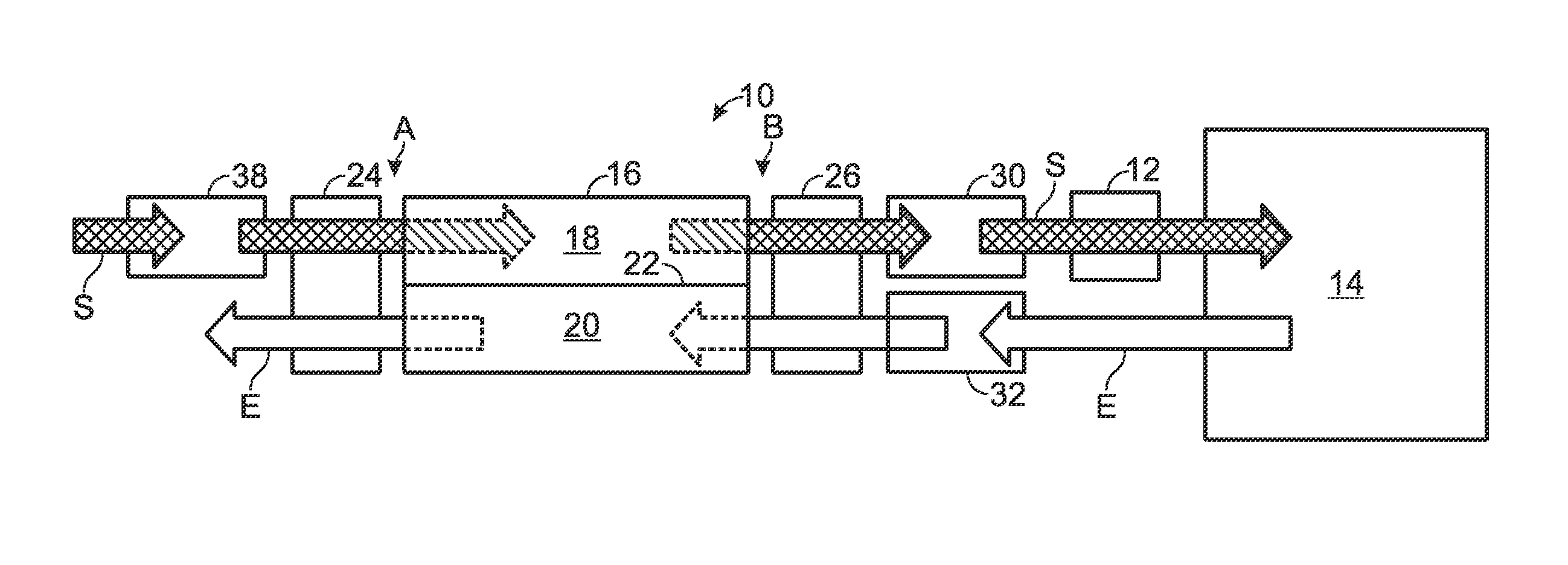

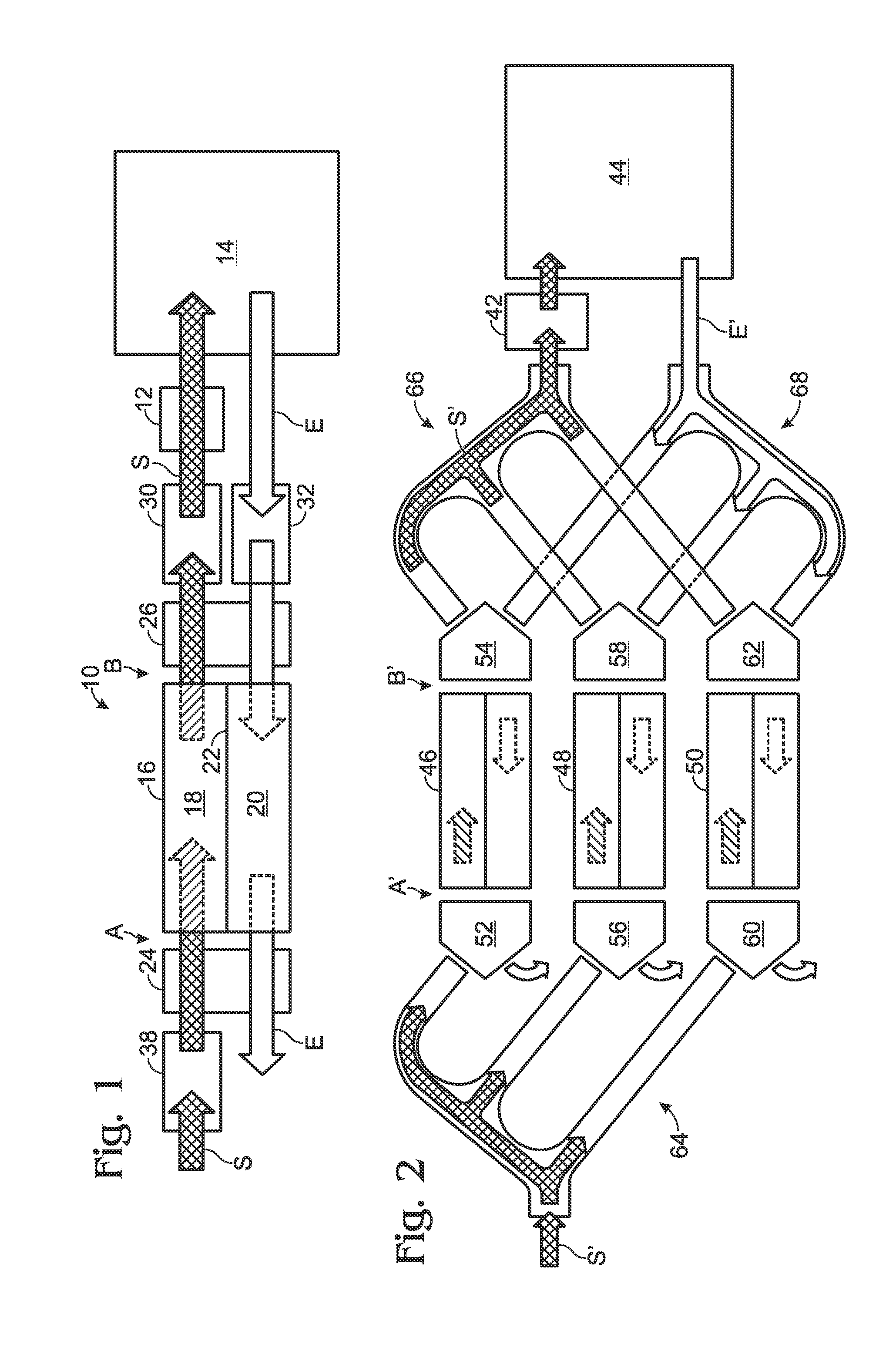

[0019]Illustrative flexible heat and moistu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com