Liquid crystal display device

a liquid crystal display and display device technology, applied in the field of liquid crystal display devices, can solve the problems of thinning the light-shielding layer and wiring, cracking of the light-shielding layer, and difficulty in forming a cell substrate by bonding the two substrates with a seal, and achieve the effect of low cost and good yield of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

Preferred Embodiment 1

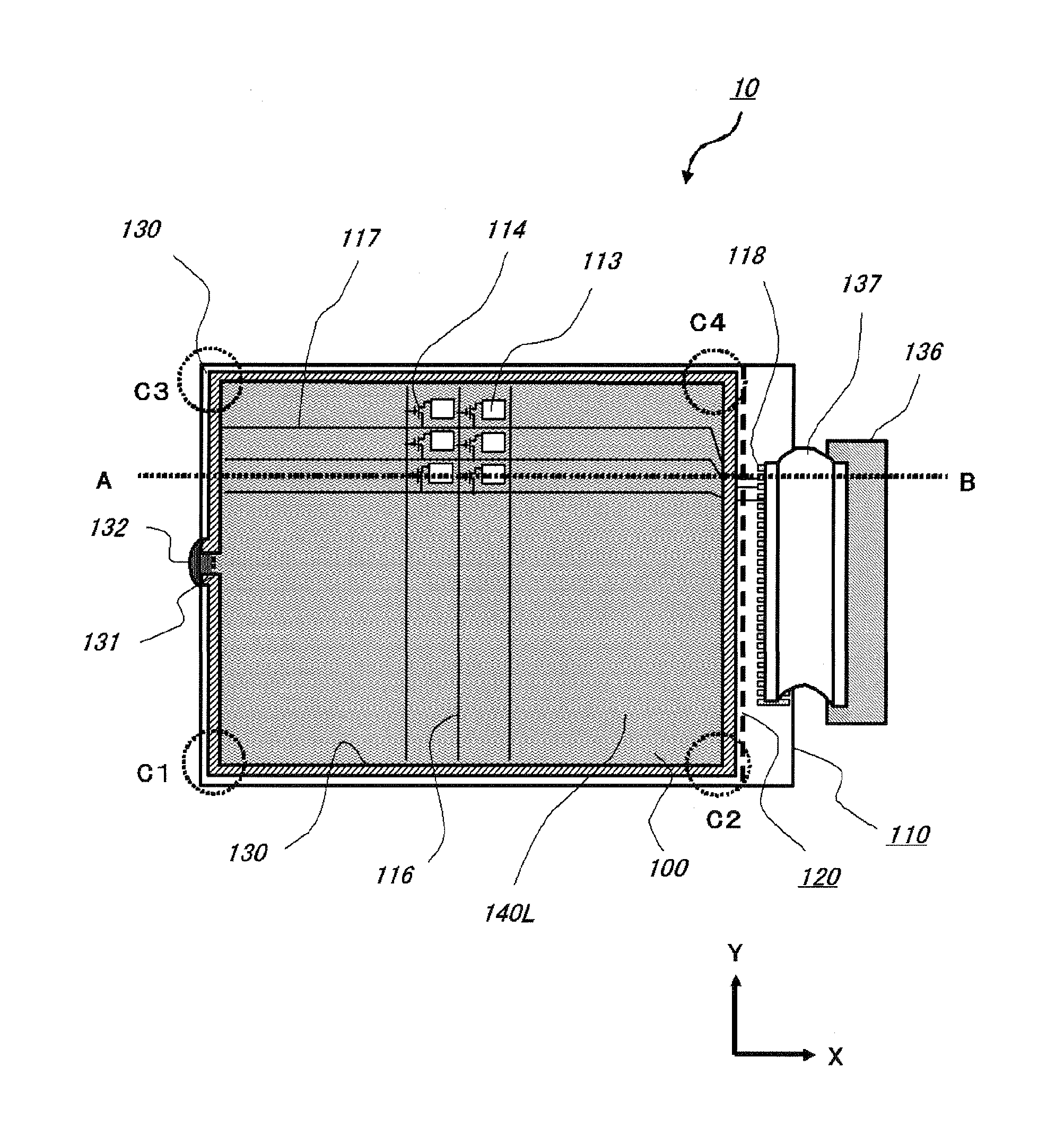

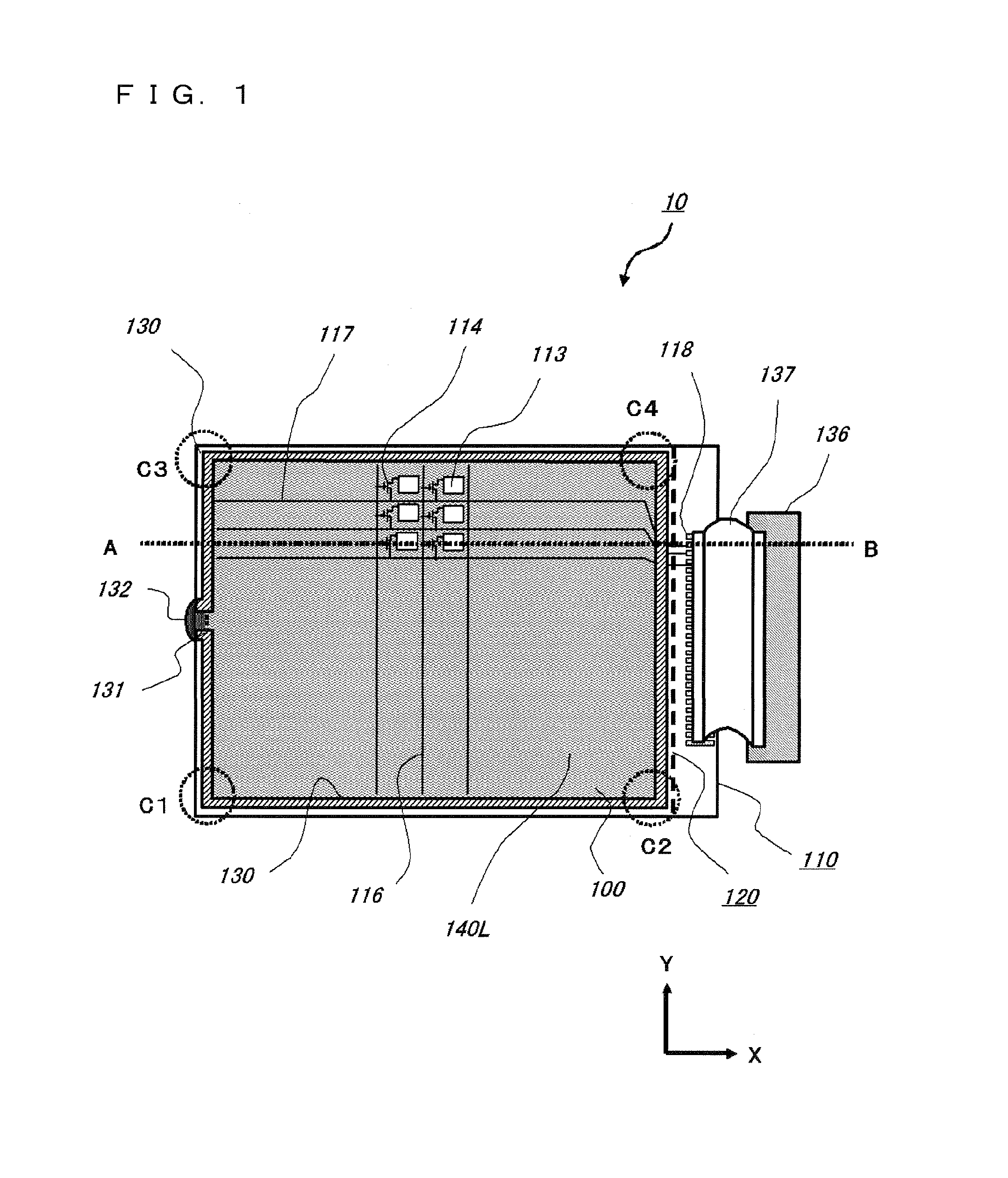

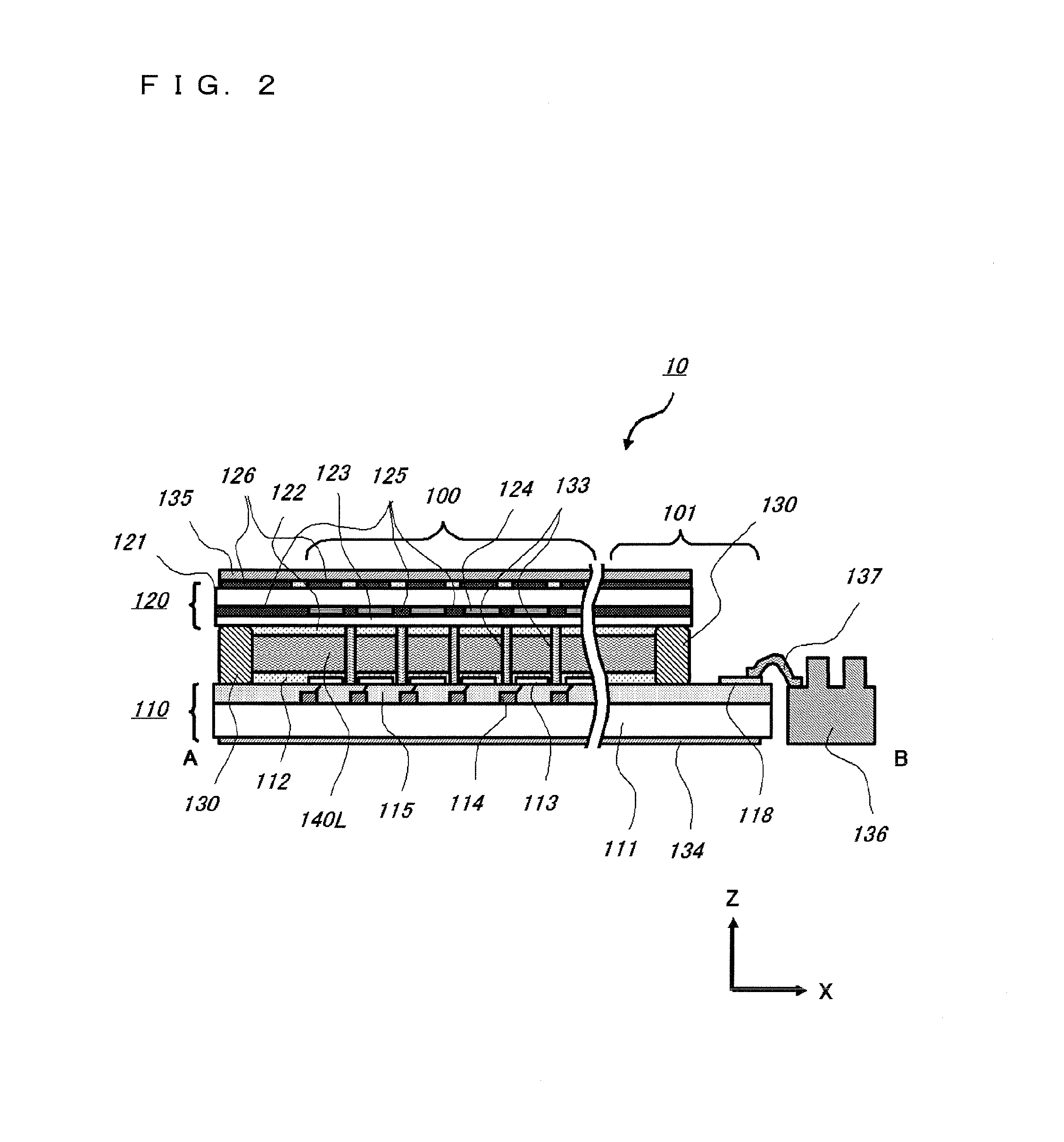

[0029]A configuration of a liquid crystal panel 10 used in a liquid crystal display device according to a preferred embodiment 1 will be described with reference to schematic diagrams of FIGS. 1, 2, 3, and 4. FIG. 1 is a plan view showing a configuration of the whole of a liquid crystal panel. FIG. 2 is a cross-sectional view as taken along the line A-B of FIG. 1. FIGS. 3 and 4 are plan views showing principal area in corner portions C1 and C2 shown in FIG. 1. These drawings are merely schematic, and do not exactly reflect the sizes of component parts, and the like, that are shown therein. To avoid complicating the drawings, as appropriate, parts other than principal parts of the invention are omitted and configurations are partially simplified. The same is true for the subsequent drawings. Moreover, in the subsequent drawings, the same component parts as those illustrated in the already-described drawings are denoted by the same reference numerals, and descrip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com