Configurations and methods for offshore ngl recovery

a technology of ngl recovery and configuration, applied in the field of configuration, can solve the problems of high capital investment and operating costs required for high recovery, inability to justify economic benefits, and inability to reduce the compression ratio of residue gas, reducing the overall compression horsepower, and reducing the heating requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

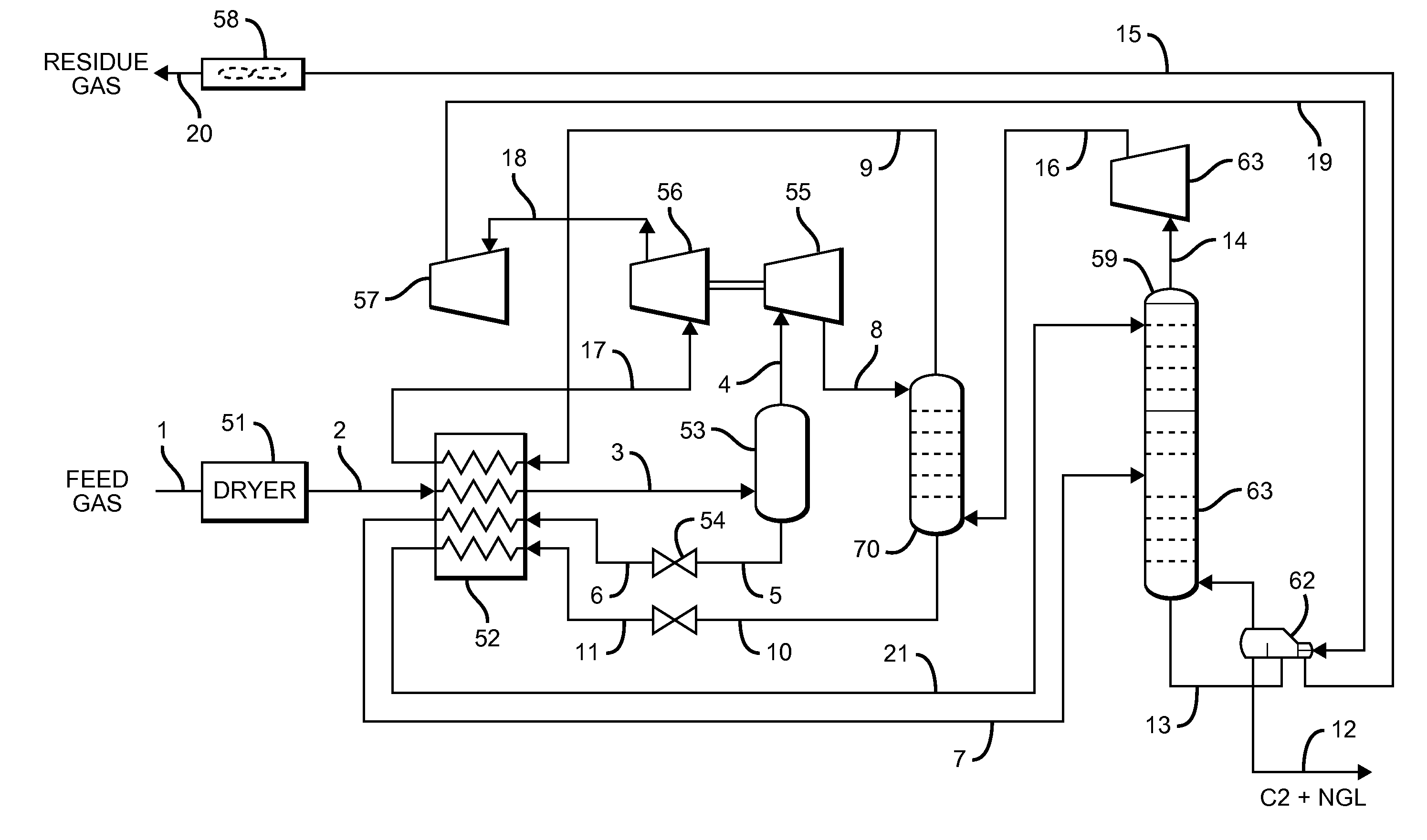

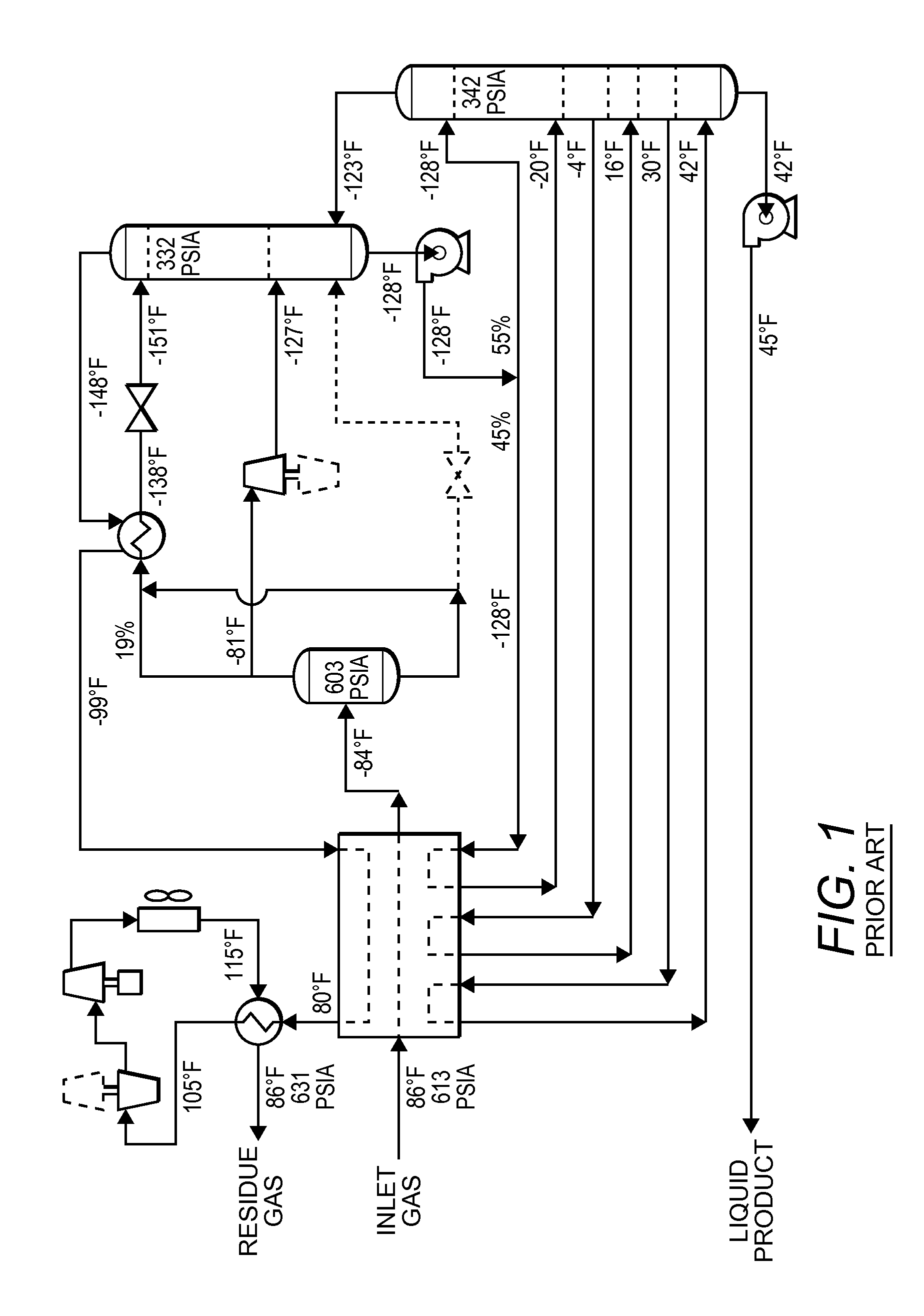

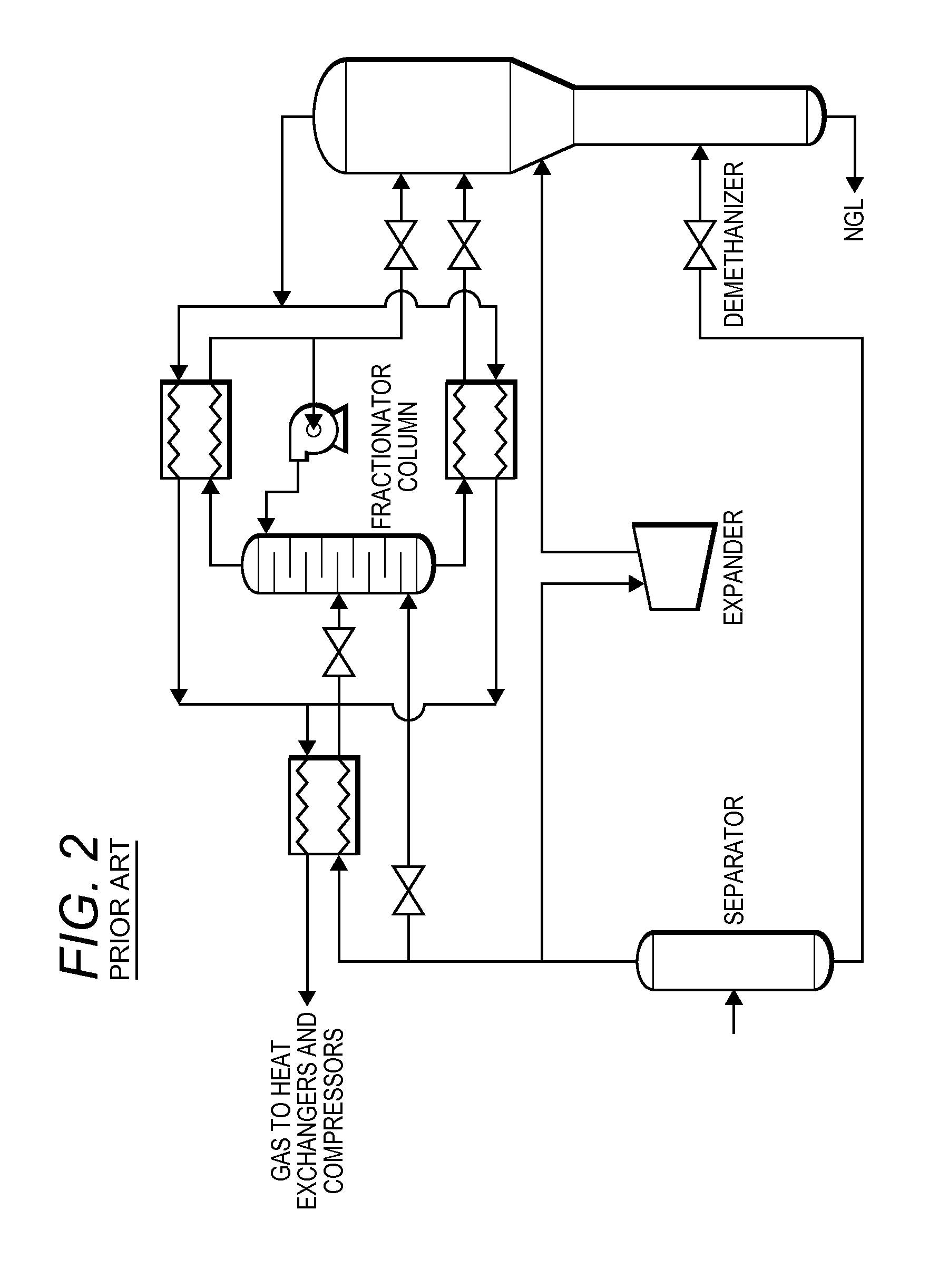

[0023]The inventor has discovered various configurations and methods of NGL recovery in which capital and operating cost can be significantly reduced, and especially in offshore applications, where a rich feed gas is processed and where C4+ recovery with moderate C2 and C3 recovery is required. Among other advantages, contemplated configurations and methods significantly reduce complexity and cost by reducing the number of equipment services, by elimination of external refrigeration and external heating while lowering residue gas compression requirements.

[0024]In particularly preferred configurations and methods, the feed gas (typically a natural gas comprising C1, C2, C3, and C4, and heavier components) is cooled at relatively high pressure to thereby effect partial condensation. The vapor and liquid phases are then separated, with the liquid phase being expanded to a lower pressure to so provide cooling to the feed gas. After reduction in pressure, the liquid phase is fed to the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com