Adjustable profile sanding and dust removal method and apparatus

a profile sanding and dust removal technology, applied in the direction of grinding/polishing apparatus, grinding/polishing safety devices, hand tools for grinding/polishing, etc., can solve the problems of secondary damage, increased the number of passes required to perform the action of surface smoothing, and reduced application efficiency, so as to reduce the number of passes required, reduce the release of potentially dangerous fine particles, and increase the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

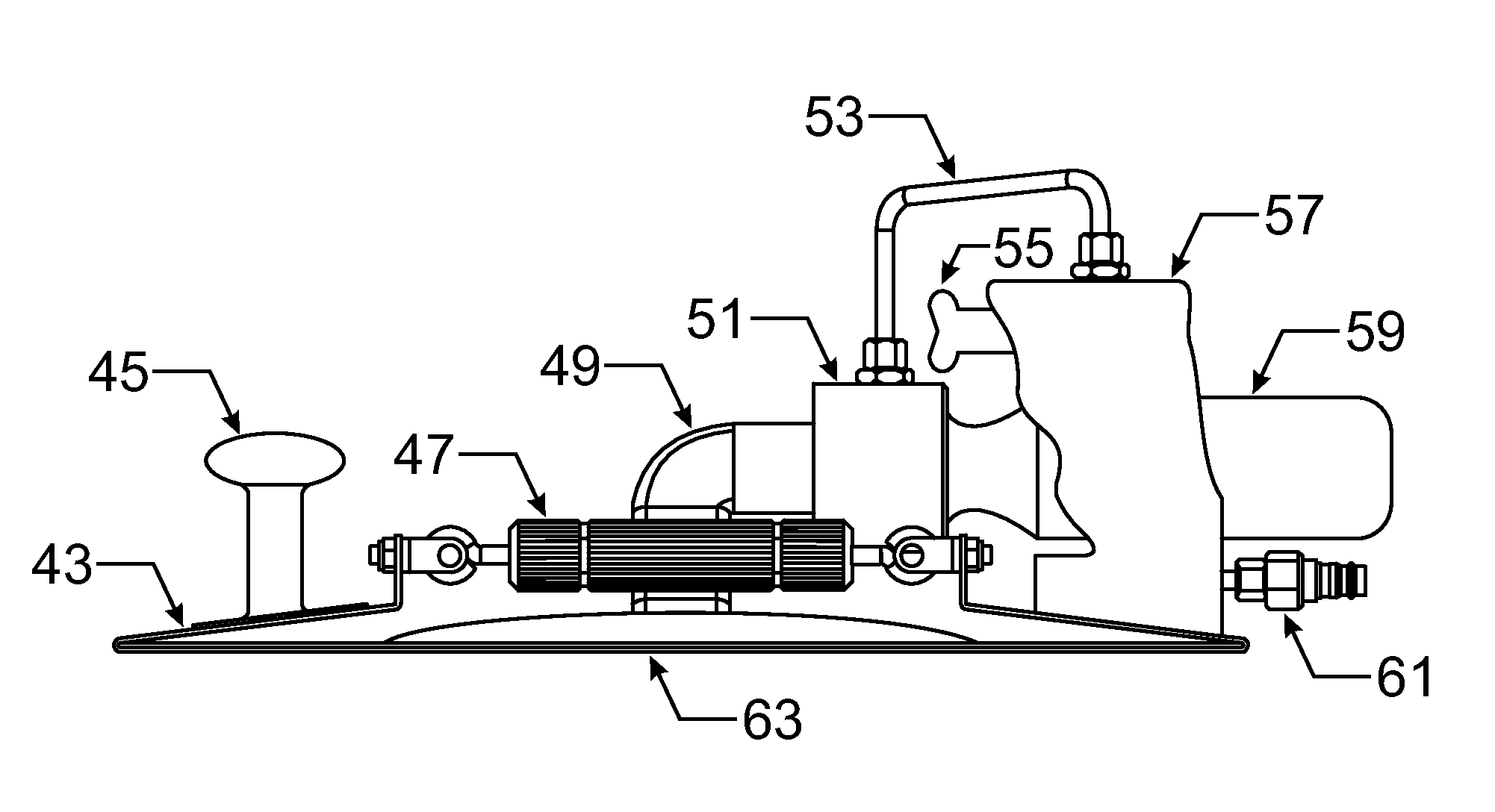

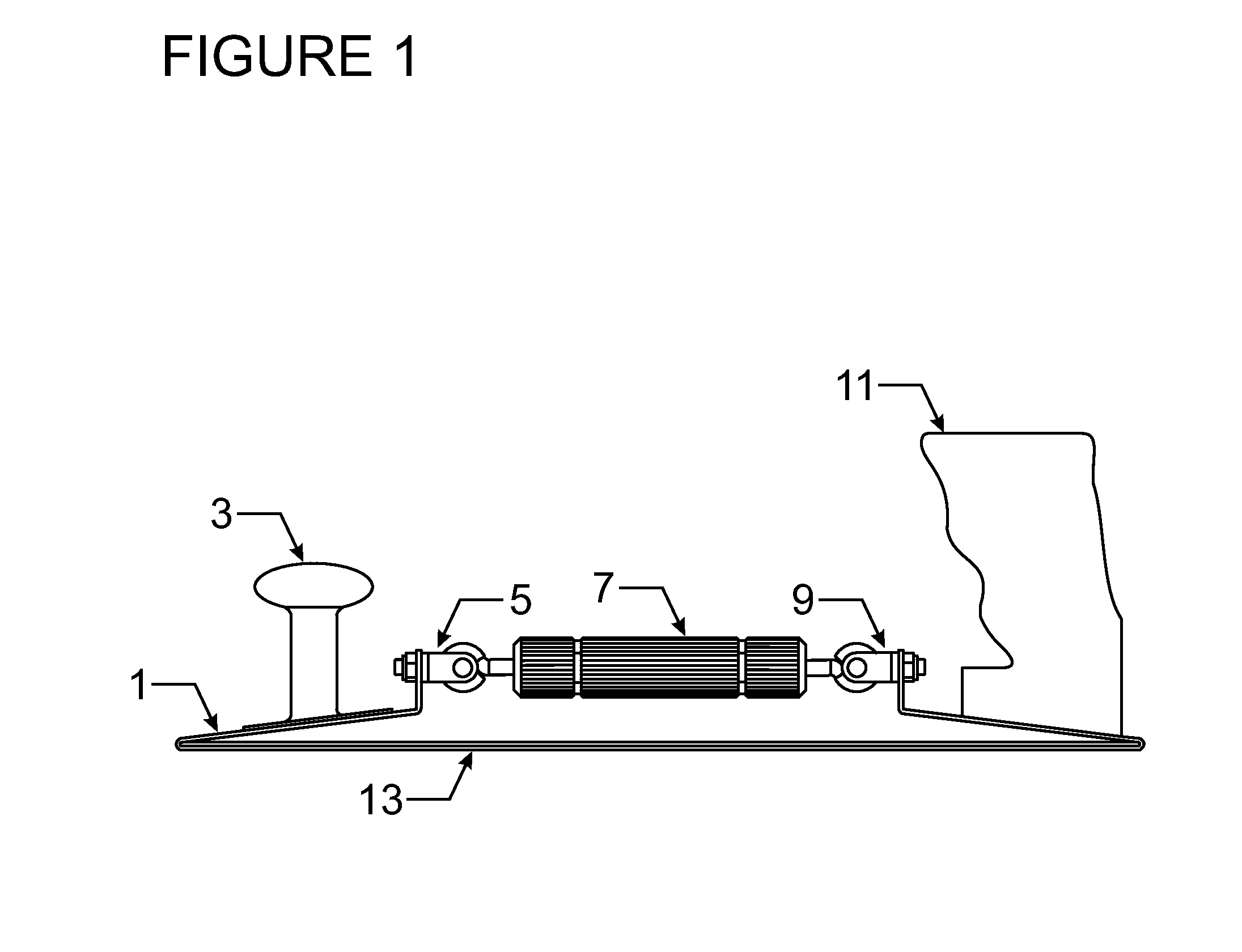

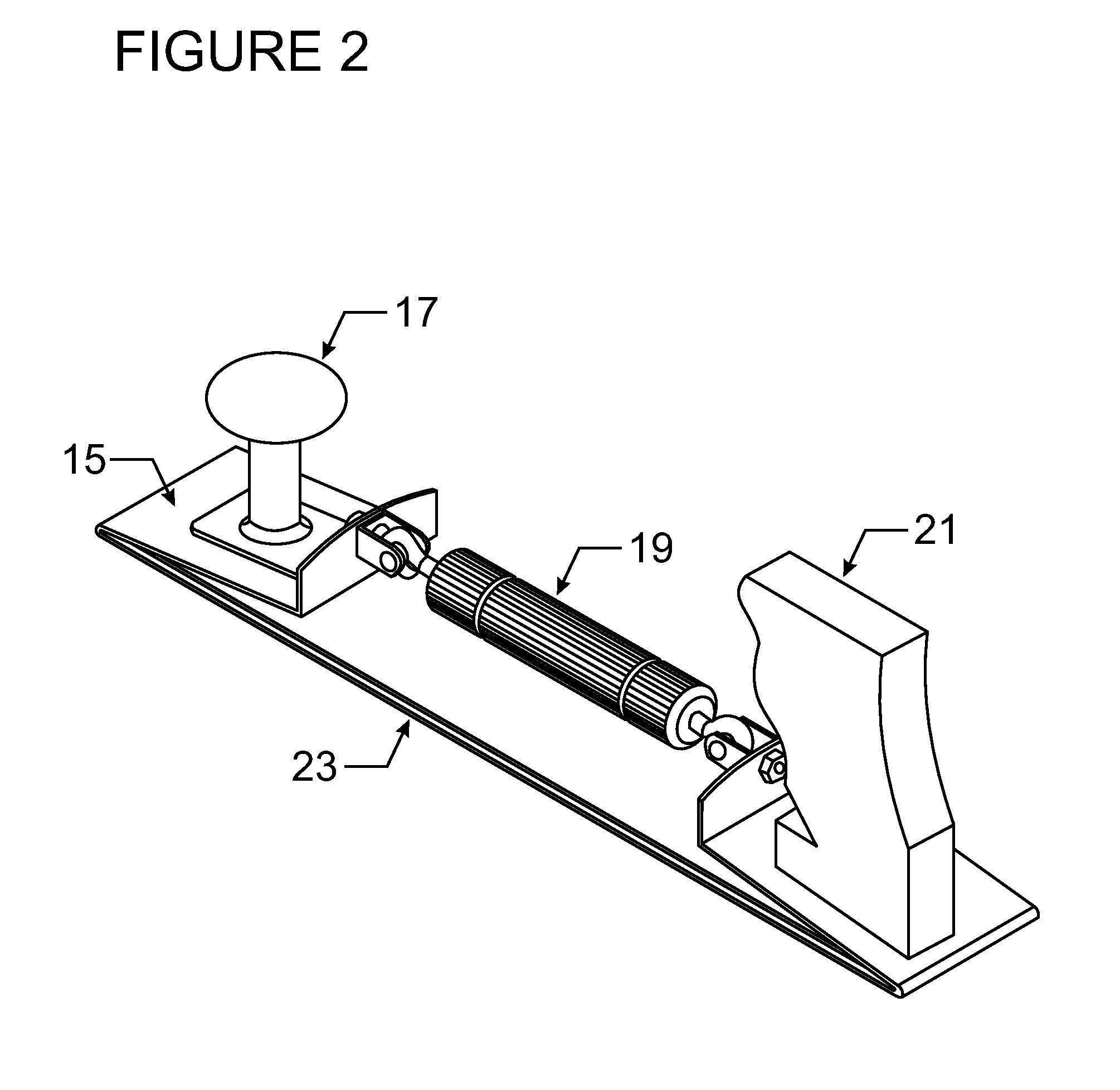

[0014]In order to better understand the embodiment of the present invention, an embodiment of the adjustable profile sanding apparatus will be described with reference to FIGS. 1 through 5. An embodiment of an adjustable profile sanding apparatus is provided as in FIG. 1 comprised of a flexible body element 1, a first grip handle 3, a first turnbuckle engagement point 5, a turnbuckle 7, a second turnbuckle engagement point 9, a second grip handle 11, and a work contact surface 13. Operation of said turnbuckle 7 provides either expansion or contraction stresses, as adjusted by the operator, at turnbuckle engagement points 5 and 9 thereby causing concave or convex deformation of work contact surface 13 as required by the work. It is understood that the configuration and geometry of grip handles 3 and 11 is variable based on application, size, and ergonomic requirements and that variation of such does not constitute a departure from the spirit of the present invention. Sandpaper is att...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| surface contour | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com