Foot membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

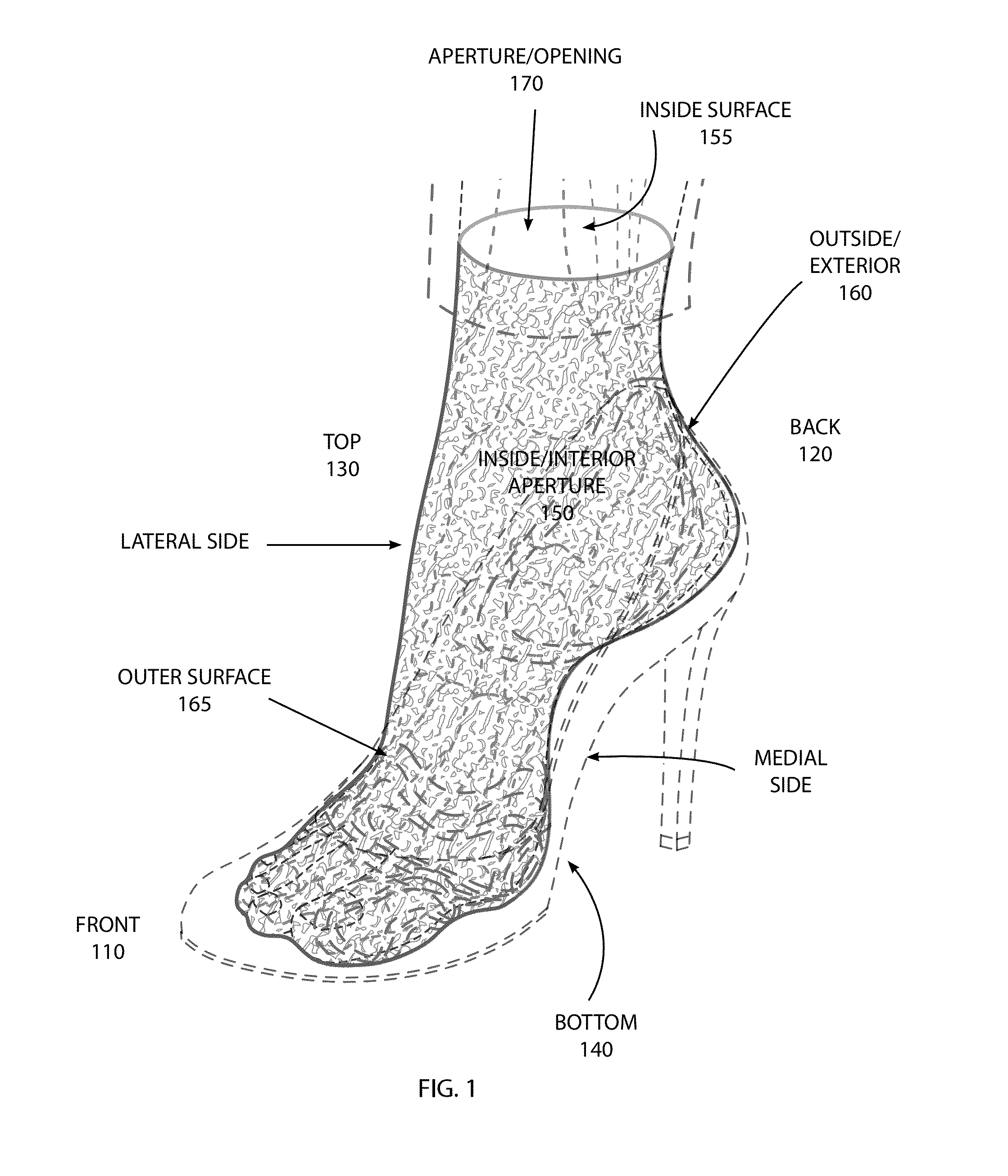

[0070]The accompanying drawings, which are incorporated in and constitute a part of this specification, illustrate embodiments of the invention and, together with the general description of the invention given above and the detailed description of an embodiment given below, serve to explain the principles of the present invention. Similar components of the devices are similarly numbered for simplicity.

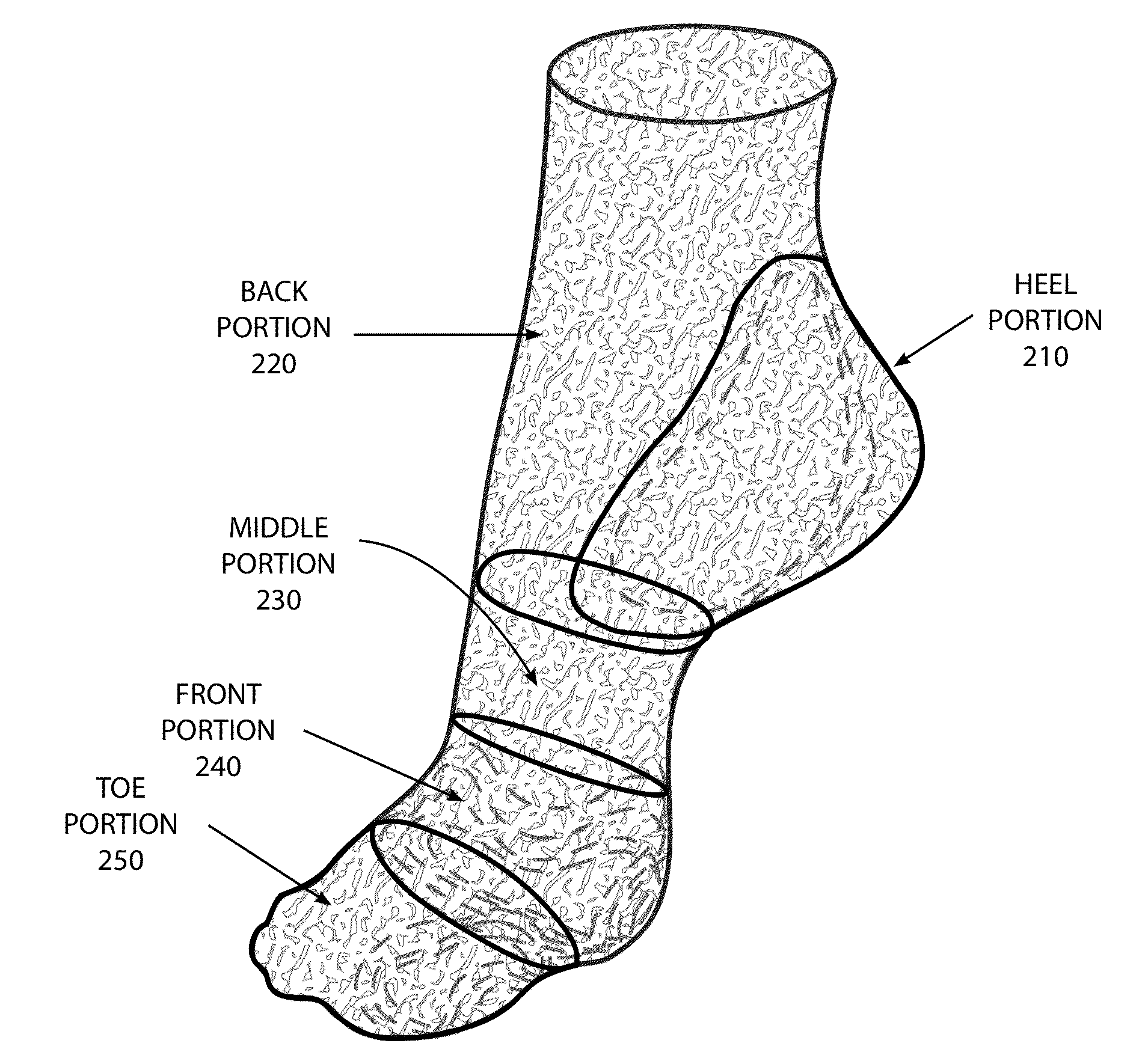

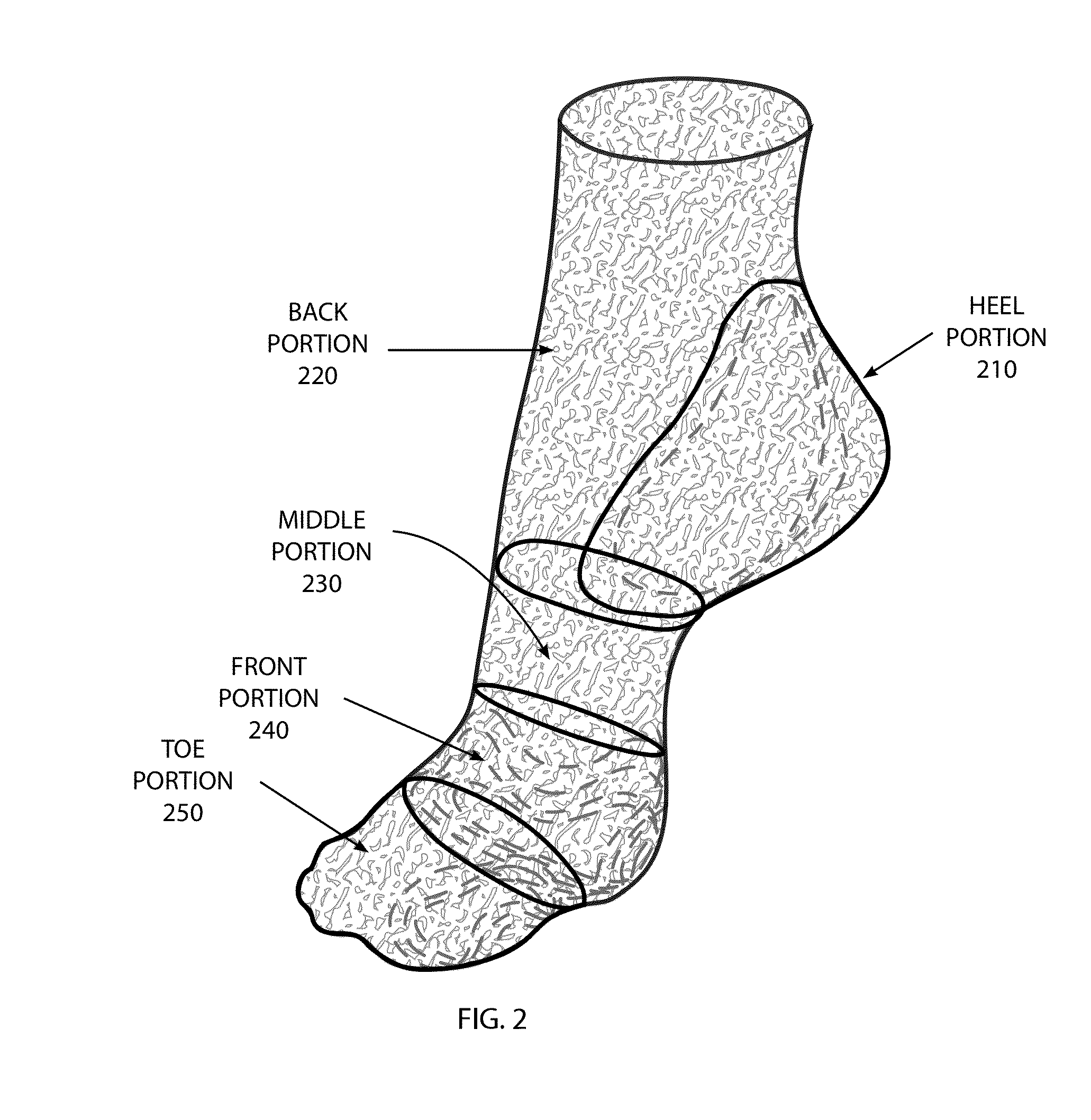

[0071]The device of the present invention comprises a unitary structure that is worn on the foot and / or adheres to the foot. The device includes a) a heel portion adapted to engage at least the plantar portion of the heel of the foot, preferably also at least some of the sides and the back (posterior) of the heel, b) a back portion adapted to engage the back of the foot behind the arch of the foot including the heel and ankle, c) a middle portion adapted to engage at least the arch of the foot and in at least some embodiments also including the sides and top of the middle portion of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com