Device having an electrically heatable honeycomb body and method for operating the honeycomb body

a technology of electrical heat dissipation and honeycomb, which is applied in the direction of machine/engine, exhaust treatment electric control, separation process, etc., can solve the problem of relative fine insulating structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

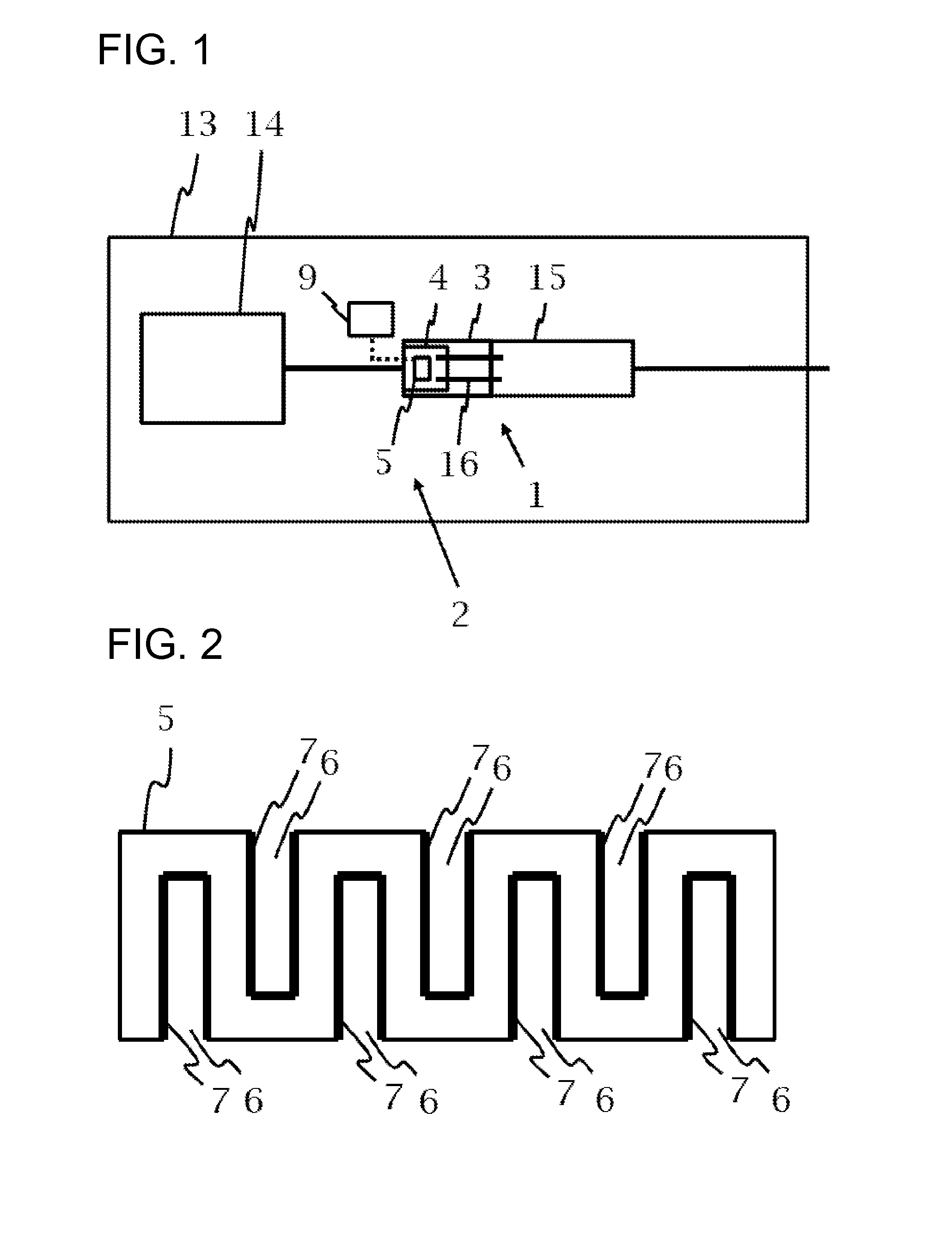

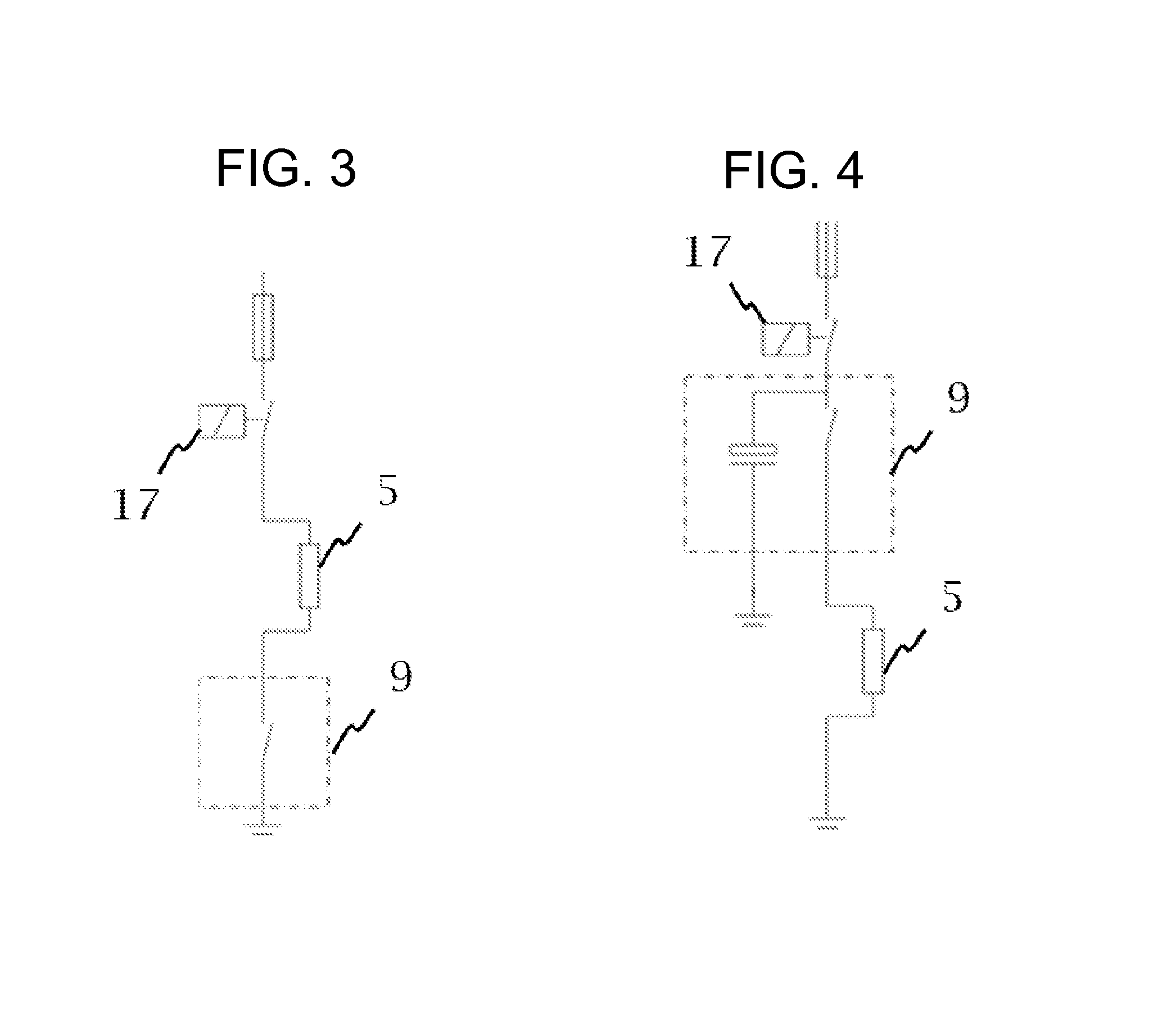

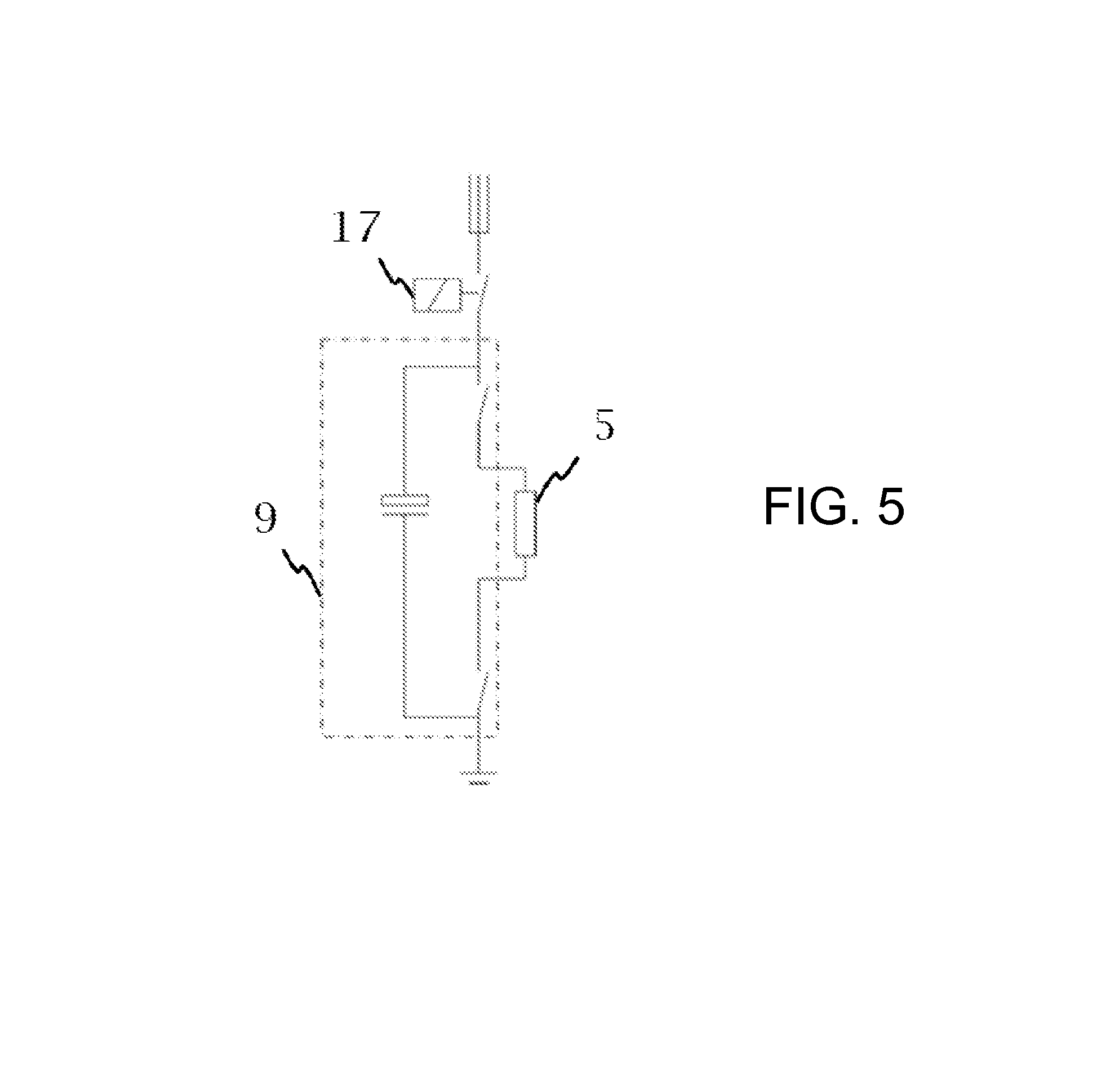

[0031]Referring now to the figures of the drawings in detail and first, particularly, to FIG. 1 thereof, there is seen a block diagram of a motor vehicle 13 having an internal combustion engine 14, an exhaust system 2 connected to the internal combustion engine 14 and a device 1 according to the invention disposed in the exhaust system 2. The device 1 includes a first honeycomb body 4 which is disposed in a casing tube 3 and in which a current-conducting structure 5 is formed. The current-conducting structure 5 is connected to a control unit 9. In addition, a second honeycomb body 15 is disposed in the casing tube 3. The first honeycomb body 4 and the second honeycomb body 15, which is disposed at a distance behind the latter, are connected through support elements 16 which project into the honeycomb bodies 4, 15 and which are disposed in sleeves in the first honeycomb body 4, with the intermediate positioning of electrical insulation.

[0032]As is seen in FIG. 2, the current-conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltages | aaaaa | aaaaa |

| voltages | aaaaa | aaaaa |

| pulsed voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com