Methods For Enhancing Paper Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

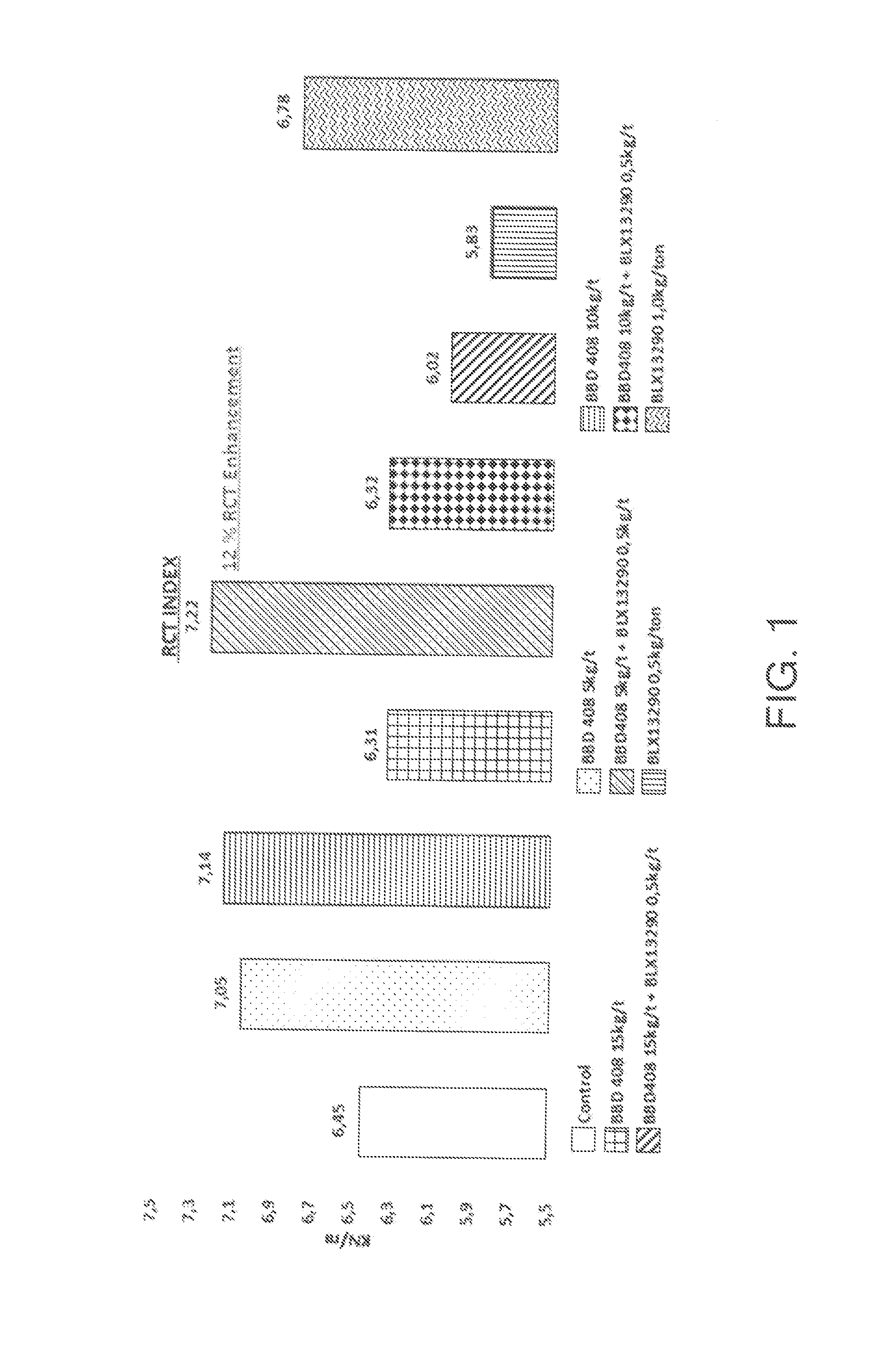

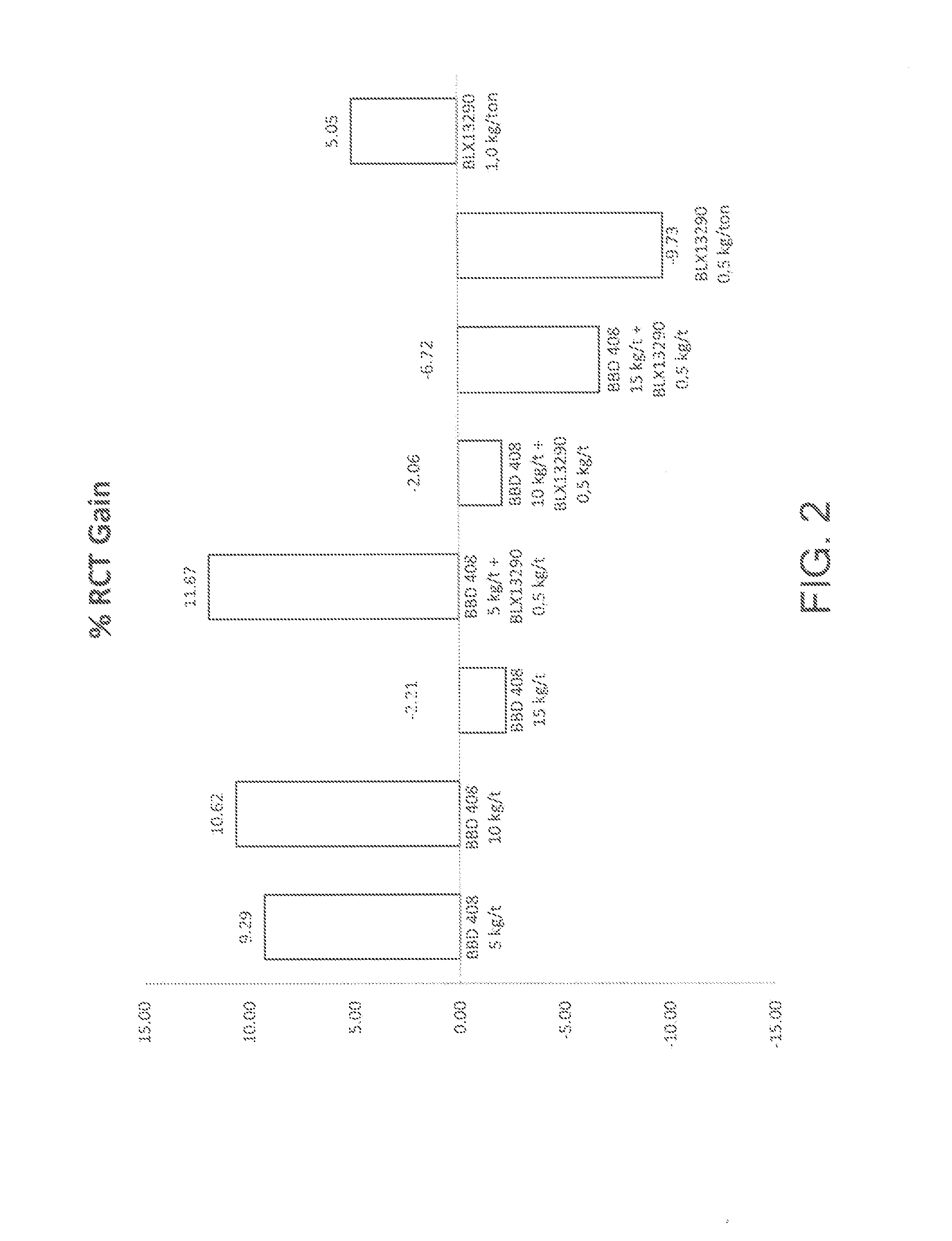

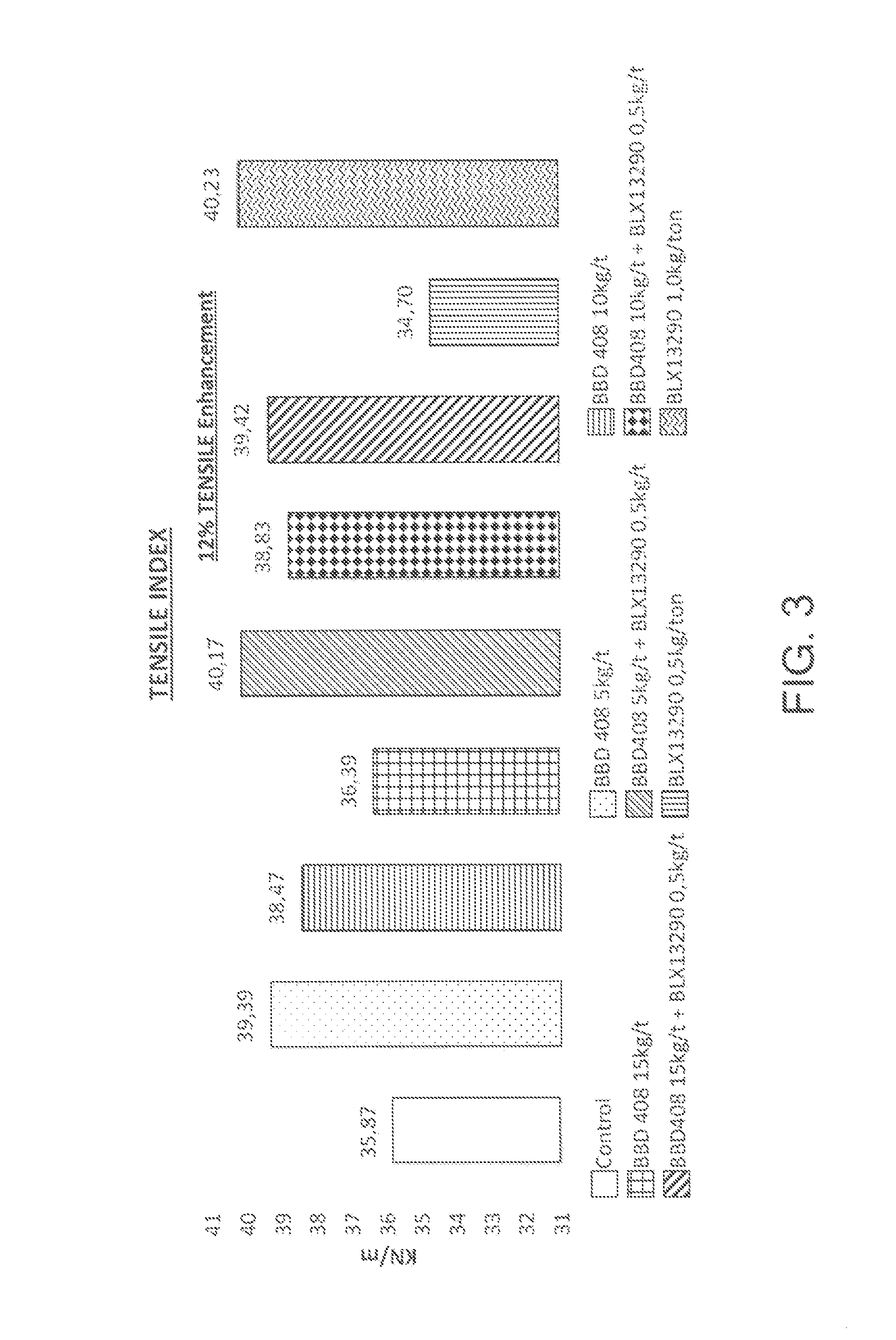

[0049]This example demonstrates the surprising and unexpected results achieved by the methods of the present invention. 110 g / m2 paper was produced on a laboratory scale consistent with the methods of the present invention. Differing amounts of enzyme (BLX 13290) and polymer (Bubond® 408) were used to produce the paper. A ring crush test (RCT) and a tensile strength test were performed on the resulting paper. FIG. 1 is a bar graph and shows results of using enzyme and polymer to increase dry strength based on the RCT. The RCT index is shown in kN / m for the various treatments. FIG. 2 is a bar graph showing the percentage gain in dry strength based on RCT using polymer, enzyme, or a combination thereof. FIG. 3 is a bar graph showing the results of using enzyme and polymer to increase dry strength based on tensile index (kN / m) for the different treatments. FIG. 4 is a bar graph showing the percentage gain in dry strength based on tensile index using polymer, enzyme, or a combination th...

example 2

[0050]This example demonstrates the surprising and unexpected results achieved by the methods of the present invention. A trial was conducted to determine if an existing program could be replaced with a new program in order to increase dry strength increase at lower cost while maintaining or improving other desirable properties. The existing program involved use of cationic polyvinylamine (0.85 kg / metric ton on a dry basis) plus anionic polyvinylamine (0.9 kg / metric ton on a dry basis). The new program involved use of cationic glyoxal polyacrylamide (0.50 kg / metric ton on a dry basis) plus laccase product (0.5 kg / metric ton on a wet basis). BLX 13290 was used as the enzyme (laccase product) and Bubond® 408 was used as the polymer application for strength enhancement. The grade was corrugated medium and testliner, including 117MI, 117NO, 150UH, 165UH, 175UH, and 190UH. The furnish was 100% recycled unbleached fiber paper Paper was produced using a Fourdrinier one ply, two press secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Solubility (mass) | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com