Multilayer article and method for making a multilayer article, blank, and insulating cup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

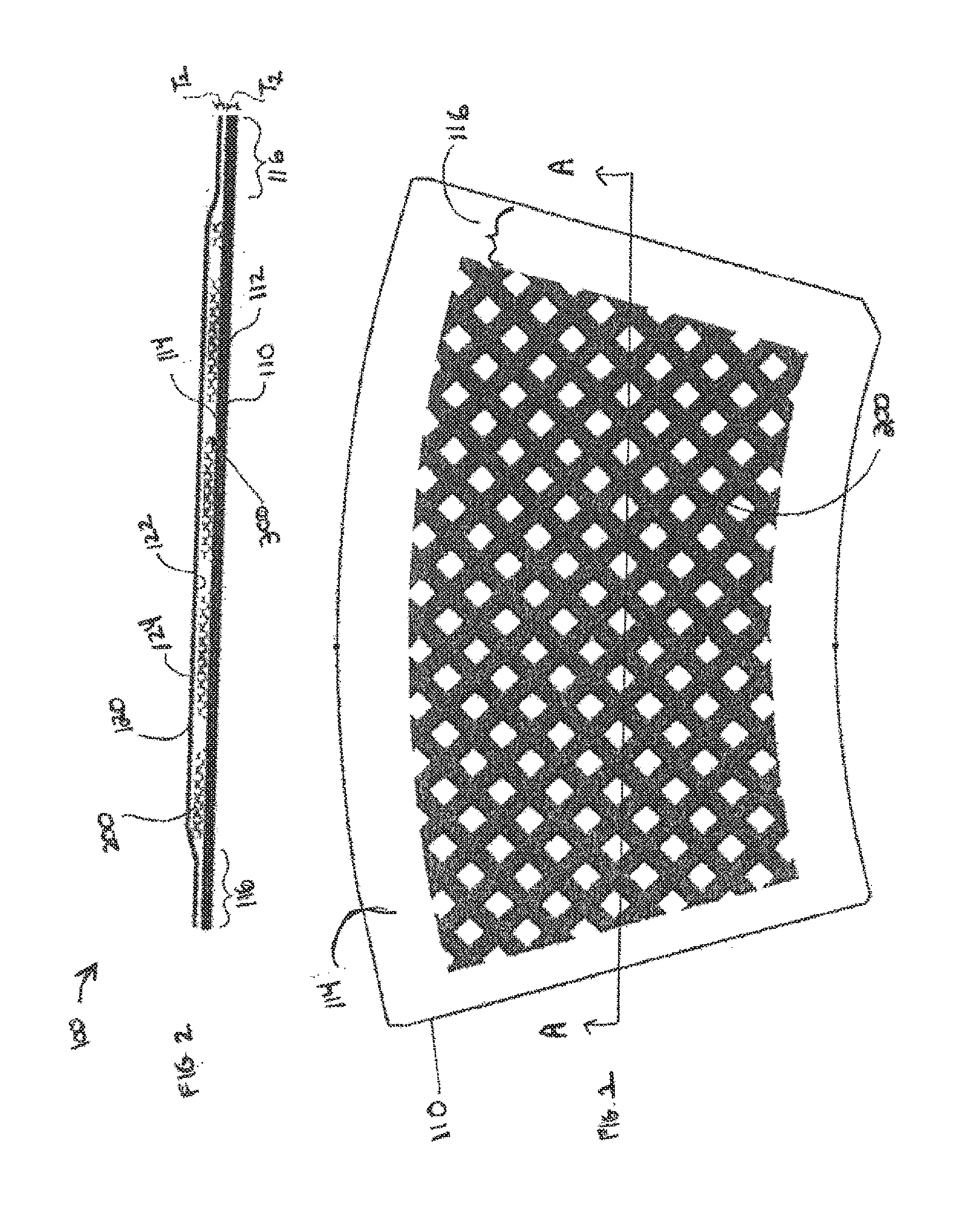

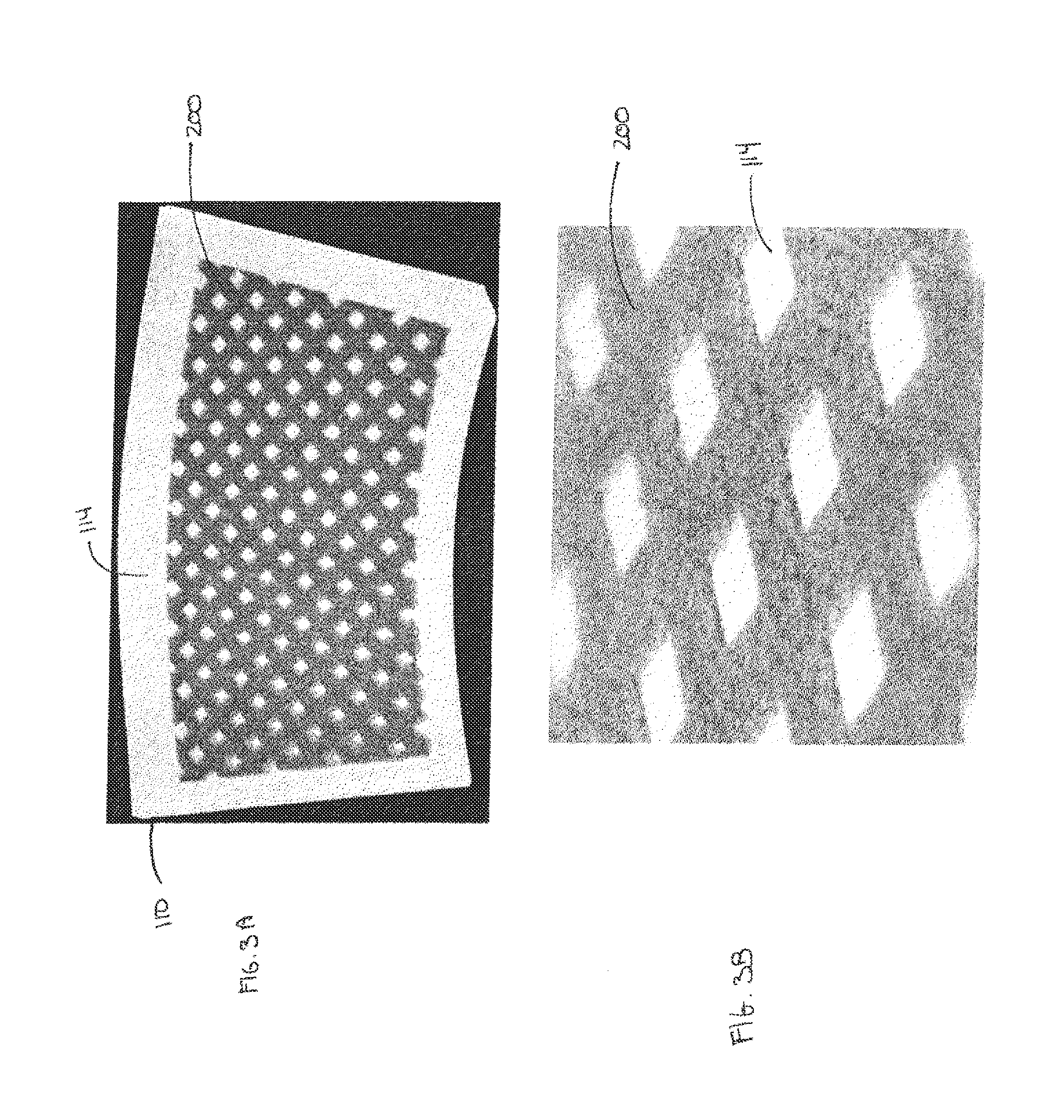

[0045]The products and methods presented herein may be used for serving, storage and transportation of beverages and food items, and other perishable and nonperishable products. The disclosed subject matter is particularly suited for serving, storage, and transportation of hot or cold beverages or food items, wherein the multi-layer configuration of the cup provides improved insulating properties to maintain the temperature of the beverage or food item contained therein during consumption, storage and / or transportation.

[0046]In accordance with the disclosed subject matter herein, the disclosed subject matter includes a method of making a multilayer article, comprising providing a first substrate having an inner surface and an outer surface and providing a second substrate having an inner surface and an outer surface. The method further includes disposing an expandable insulating material on the inner surface of at least one of the first substrate and the second substrate, wherein th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com