Folding apparatus for the containment and transport of bottles and method of use

a bottle containment and bottle technology, applied in the field of shipping containers, can solve the problems of inability to withstand inconvenient disassembly and storage, and inability to successfully resist the predictable rigors of current containers, etc., and achieves the effects of convenient disassembly and storage, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]As described above, the present invention provides a new and useful apparatus for the containment and transport of bottles which is lightweight, inexpensive to manufacture, stronger and more resilient than current shipping containers, and is easily disassembled and compactly stored for reuse. Typical situations and settings that would benefit from the availability of such an apparatus would be: large scale manufacturing and bottling plants and distributers, as well as end user retail vendors of bottled goods such as wine. The following description and accompanying drawings disclose at least one version of such a device.

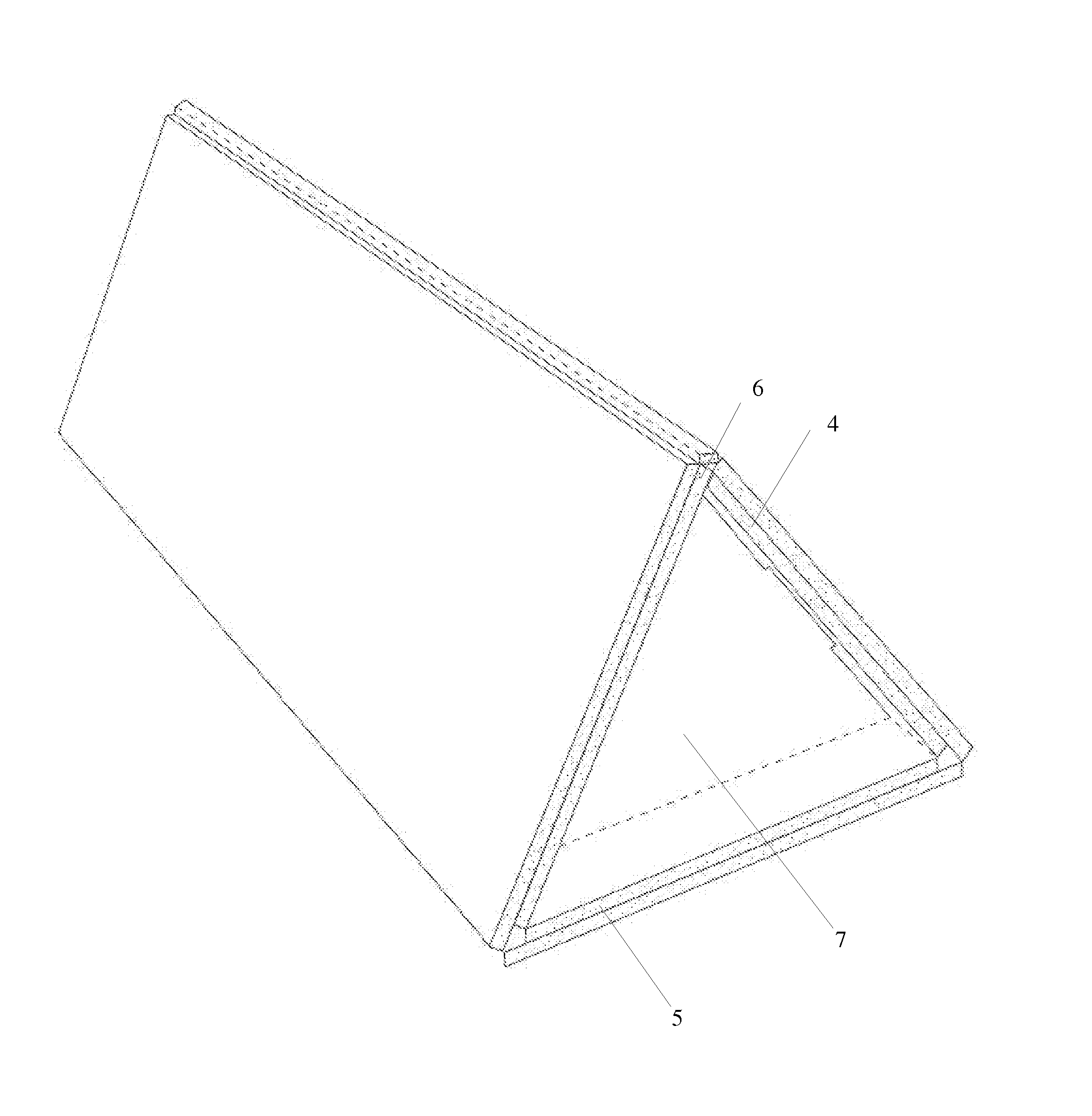

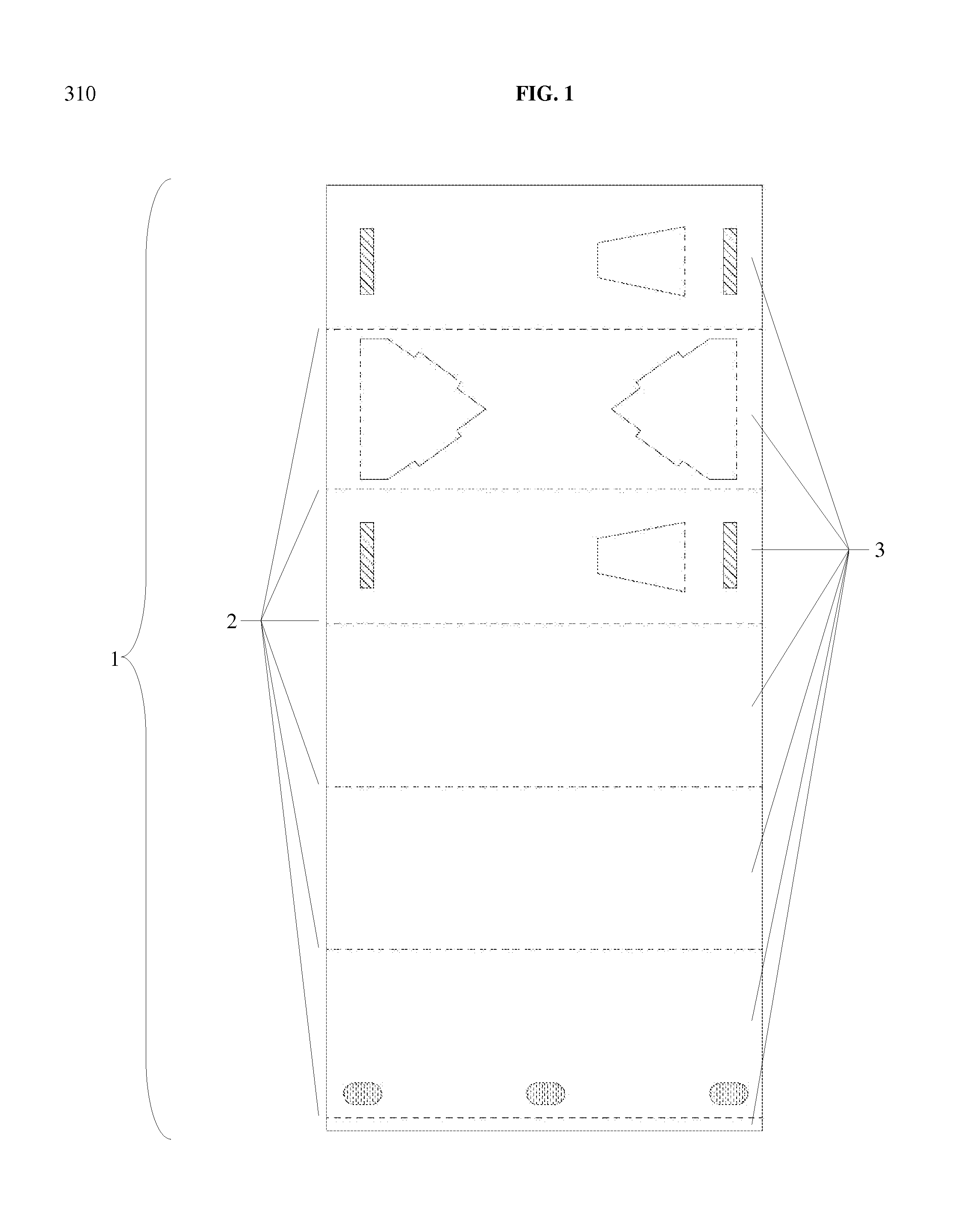

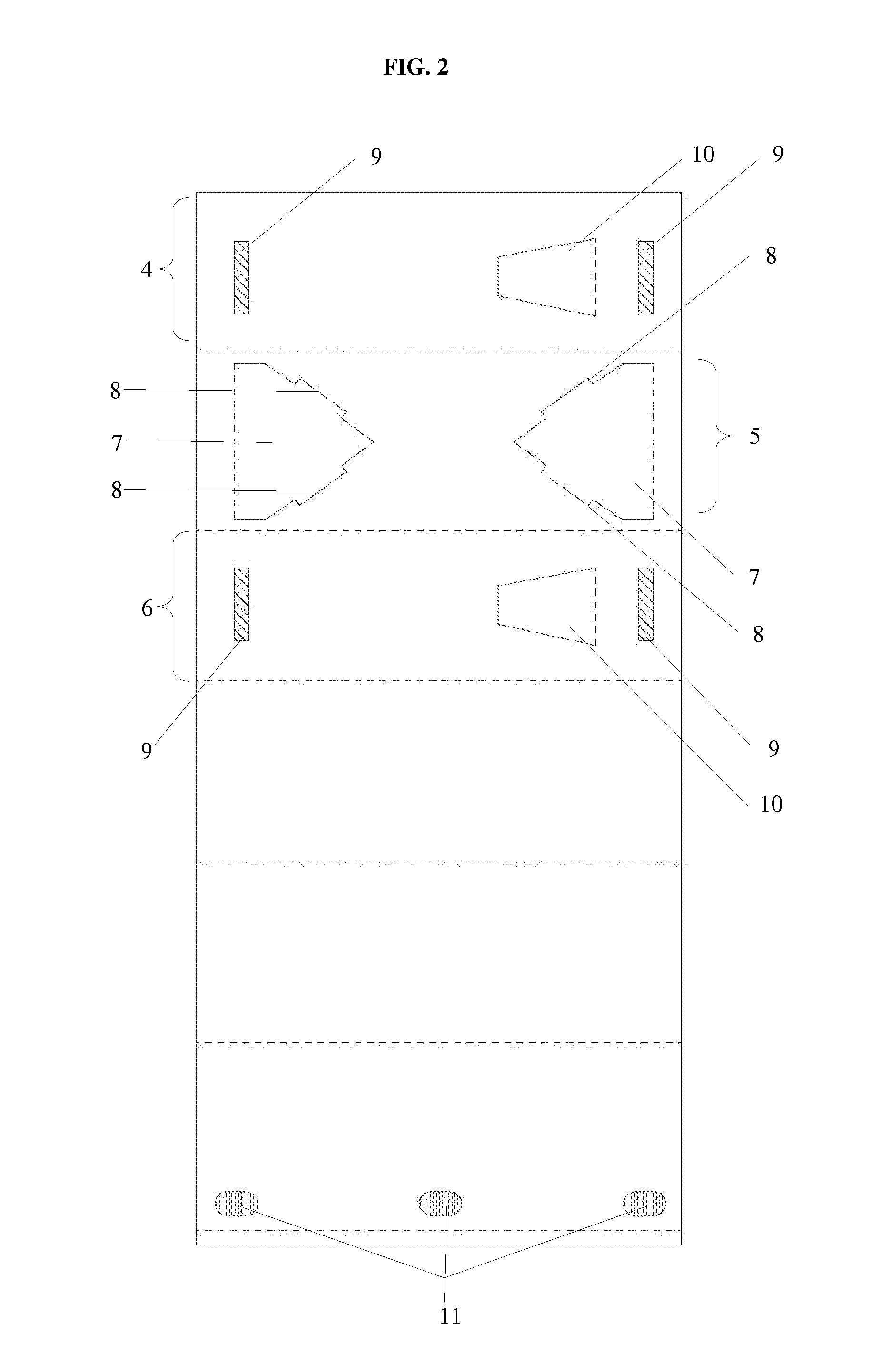

[0025]Referring now to the invention in more detail, in FIG. 1 to FIG. 7 there is shown a folding apparatus for the containment of bottles comprising a sheet 1 made of a substantially rigid material such as corrugated cardboard or foam core. Said sheet having a generally two dimensional and rectangular shape, and an inside surface and an outside surface. The she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com