Integrated thin film evaporation thermal spreader and planar heat pipe heat sink

a technology of integrated thin film evaporation and heat sink, which is applied in the direction of basic electric elements, semiconductor devices, lighting and heating apparatus, etc., can solve the problems of insufficient applicability, large heat dissipation difficulty, and severe problems in the 3d die stack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

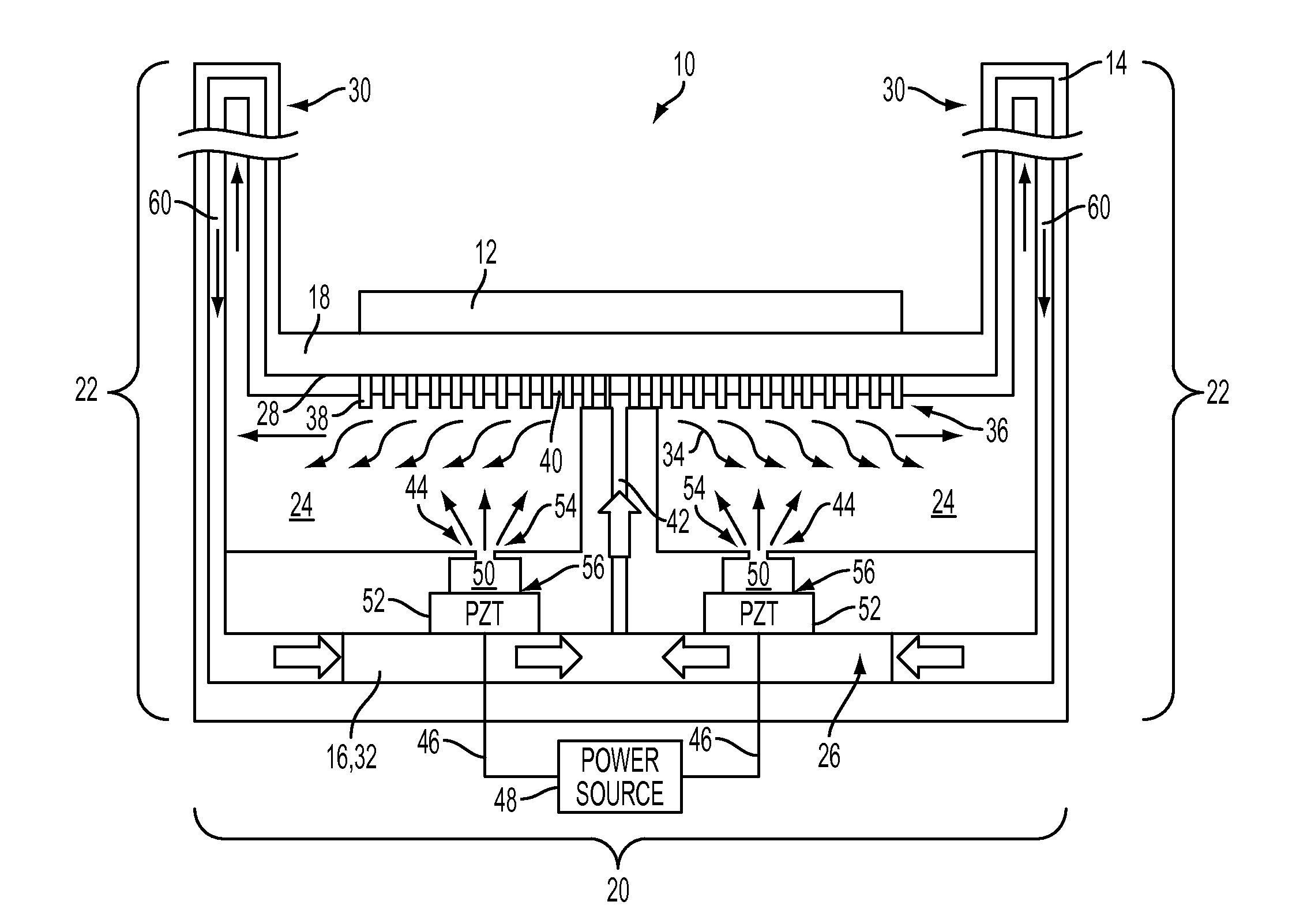

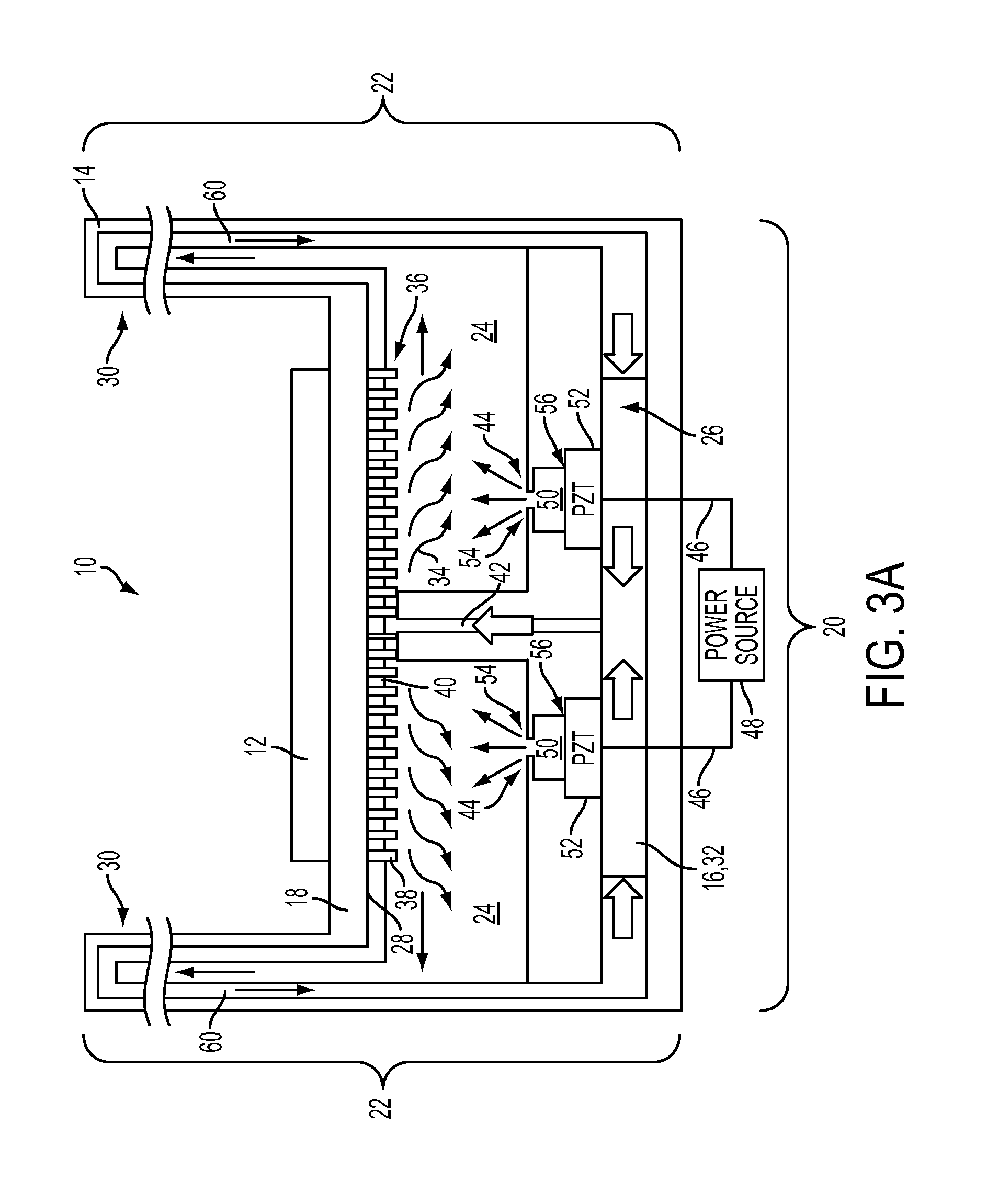

[0032]This present application combines an actively driven thin film evaporator for spreading heat with an integrated planar heat pipe extended surface for heat sinking. The thin film evaporator allows for a high rate of heat removal to remove hot spots, and the integrated planar heat pipe transports heat from the thin film evaporator to an extended surface for dissipation to the environment or sinking to an interposer layer.

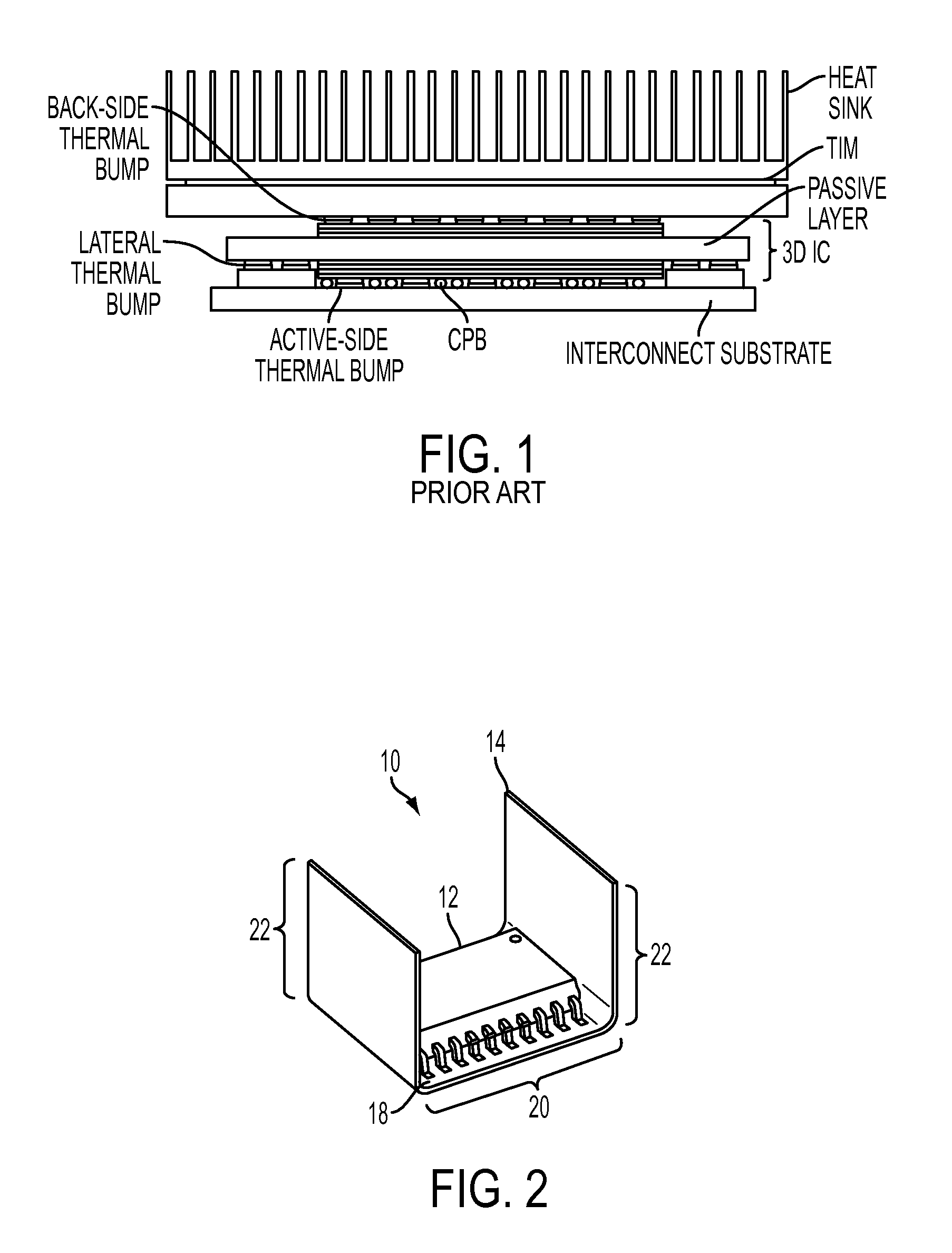

[0033]With reference to FIG. 2, a perspective view of a heat dissipation device 10 of the present application is provided. The heat dissipation device 10 provides thermal spreading and cooling to an associated heat-producing body 12, such as an integrated circuit (IC) package (illustrated). Typically, but not necessarily, the IC package is three-dimensional (3D). As will be seen, the heat dissipation device 10 is capable of managing heat fluxes of 10 to 1000 Watts per square centimeter (W / cm2) or more, such as 100 W / cm2.

[0034]The heat dissipation device 10 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com