Feed forward parameter values for use in theoretically generating spectra

a parameter value and theoretical spectra technology, applied in the field of optical monitoring, can solve the problems of low reliability or requiring other techniques, complex optical models with a large number of variable input parameters can suffer similar problems of computational load, and possible false fitting of optical parameters, so as to reduce the size of the library, reduce the processing load for calculation of the layer stack, and improve the reliability of the endpoint system to detect a desired polishing endpoint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

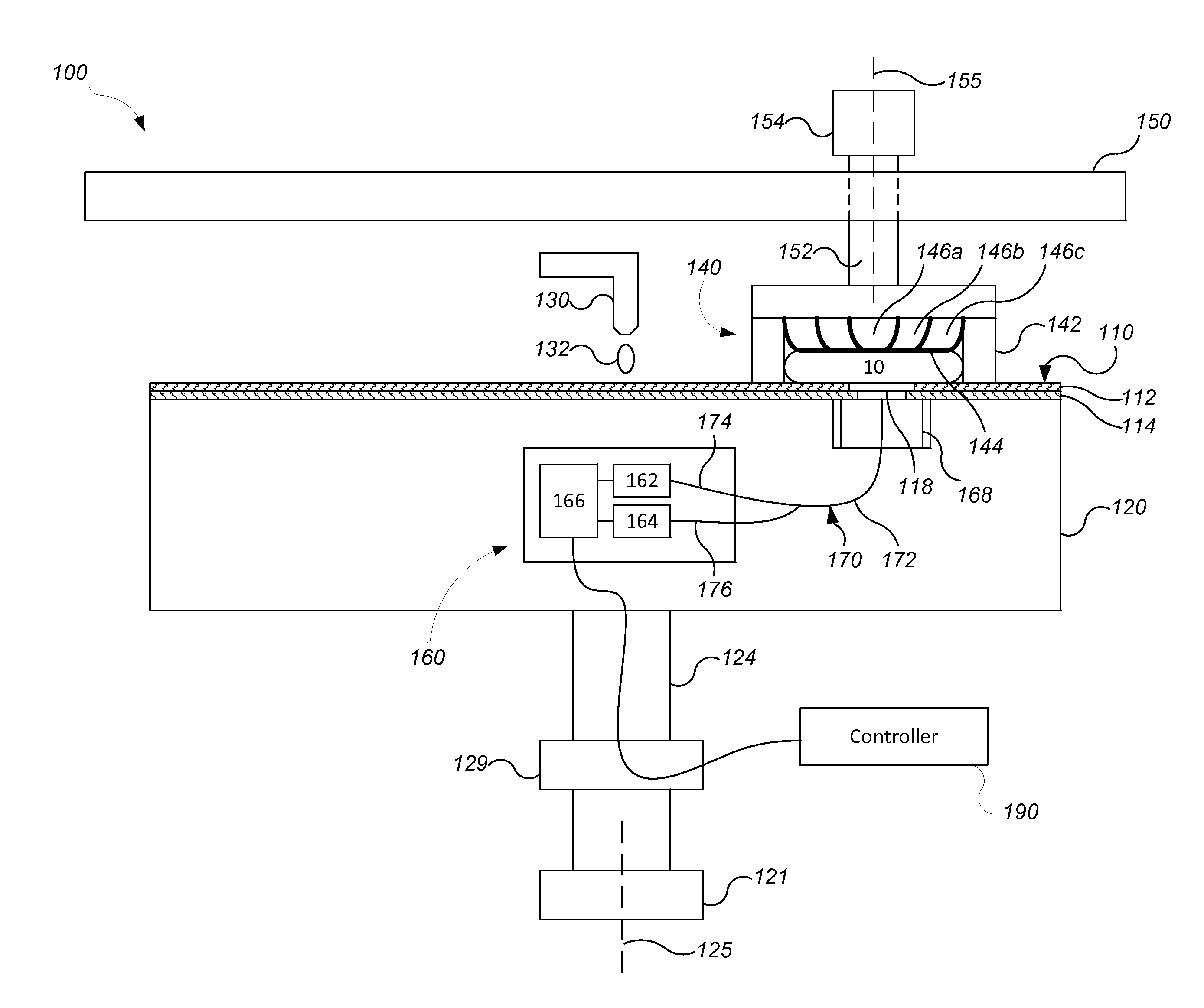

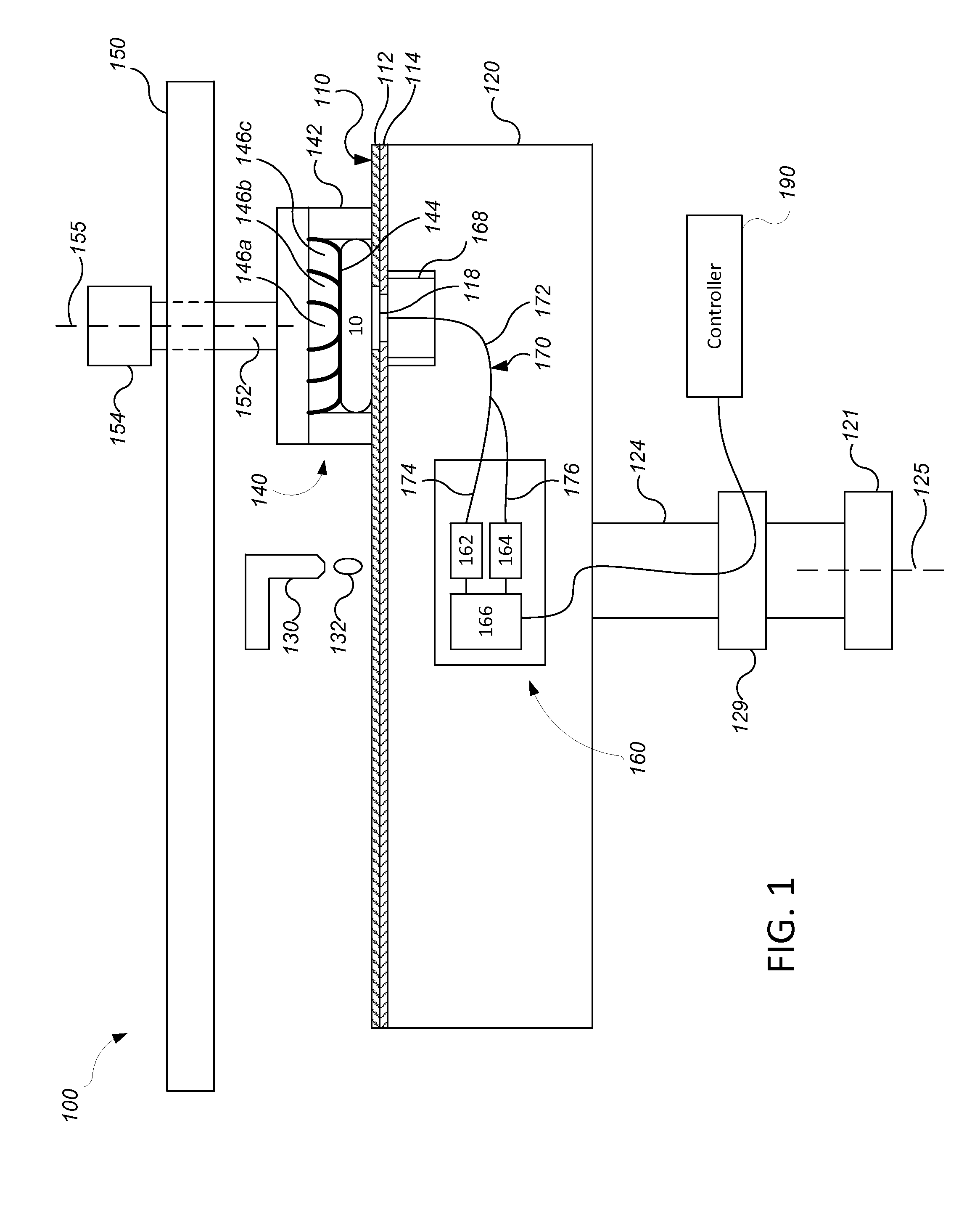

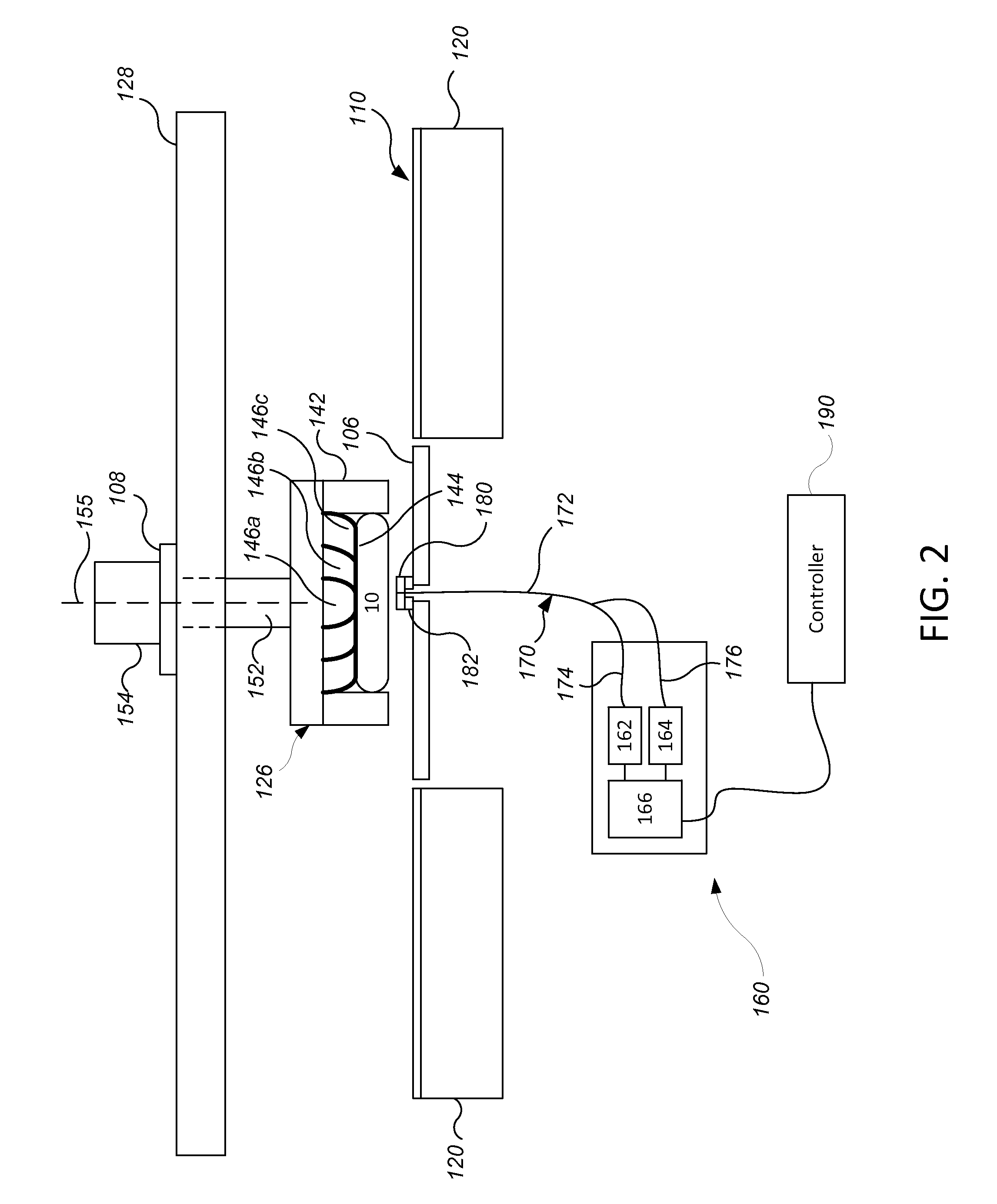

[0023]One optical monitoring technique for controlling a polishing operation is to measure a spectrum of light reflected from a substrate, either in-situ during polishing or at an in-line metrology station, and compare the measured spectrum to a plurality of reference spectra from a library, and identify a best-matching reference spectrum. The reference spectra can be calculated from an optical model by varying multiple input parameters. Ideally, the optical model has sufficient degrees of freedom to generate a library of reference spectra that spans the likely range of variation of incoming substrates.

[0024]One potential problem is the size of the library of reference spectra. For reliable polishing of some types of substrates, the library of reference spectra may have reference spectra that span the likely range of variations in thickness and / or other parameters of the underlying layers of incoming substrates, and consequently increasing the size of the library. In some examples, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com