Heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

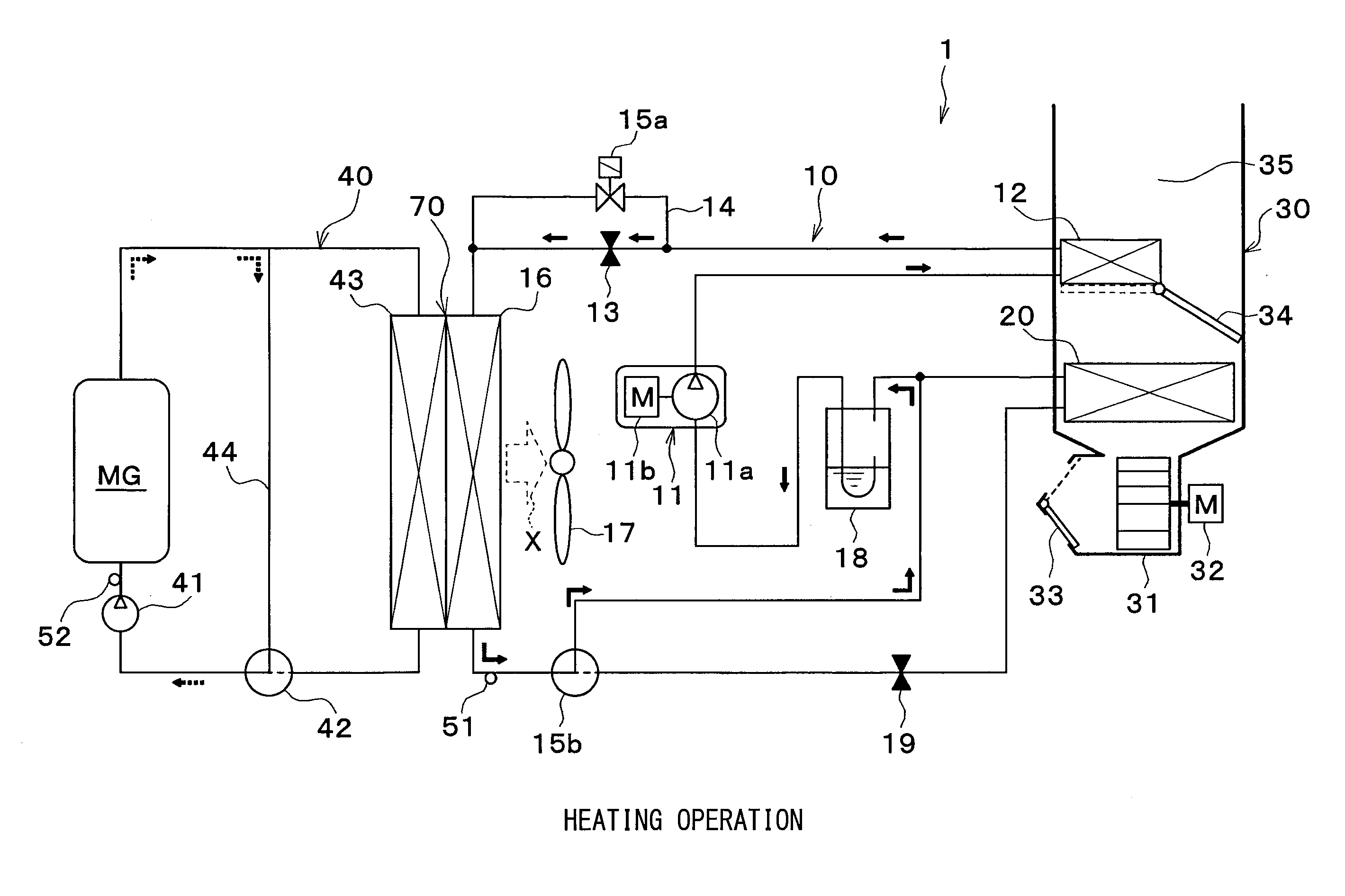

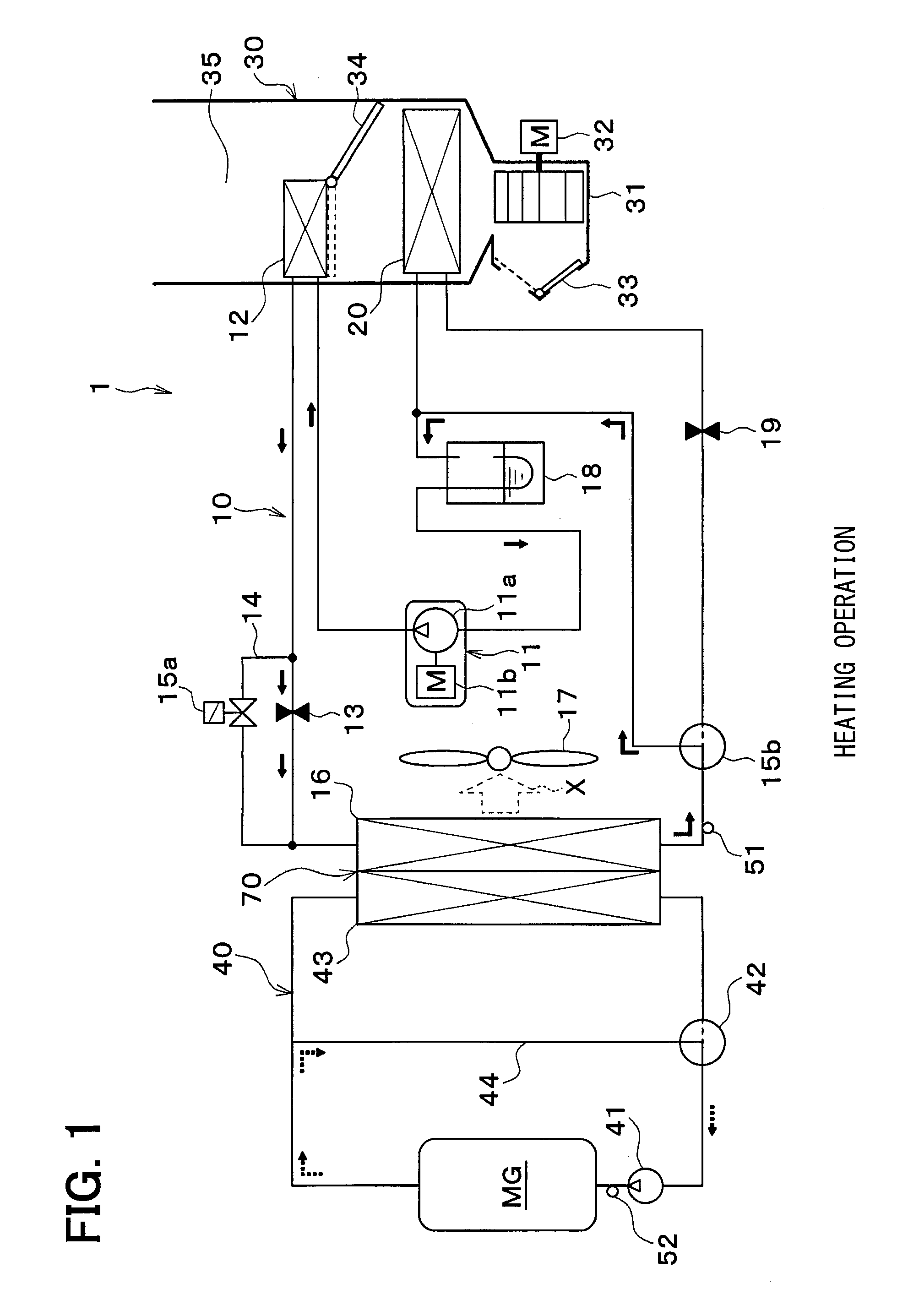

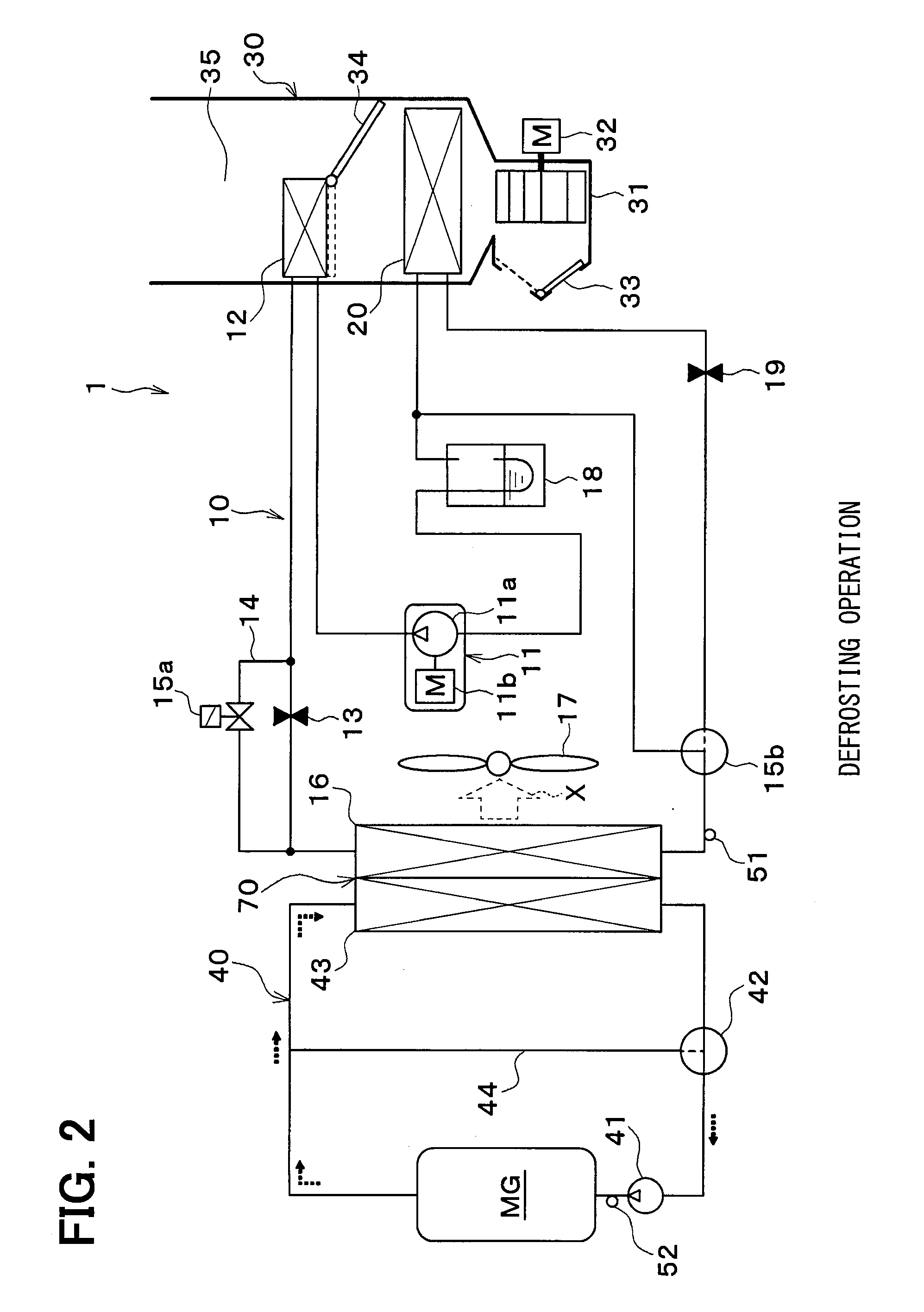

[0090]A first embodiment of the present disclosure will be described with reference to FIGS. 1 to 10. In the present embodiment, a heat exchanger 70 of the present disclosure is used for a heat pump cycle 10 of a vehicle air conditioner 1 that conditions a temperature of air blown in to a vehicle compartment. FIGS. 1 to 3 are general configuration diagrams showing the vehicle air conditioner 1 of the present first embodiment.

[0091]The vehicle air conditioner 1 is used for a hybrid vehicle that obtains a driving force for vehicle-running from an internal combustion engine (engine) and from a running electric motor MG.

[0092]The hybrid vehicle operates or stops the engine depending on a running load of the vehicle. The hybrid vehicle is capable of switching its running state, for example, between a running state, in which the driving force is obtained from both the engine and the running electric motor MG, and a running state, in which the engine is stopped and the driving force is obt...

second embodiment

[0224]Next, a second embodiment of the present disclosure will be described in reference to FIG. 11. The second embodiment is different from the first embodiment in shape of header tank 75. FIG. 11 is a perspective sectional diagram showing a heat exchanger 70 of the second embodiment.

[0225]As shown in FIG. 11, a header tank 75 of the heat exchanger 70 includes a header plate 751 to which both refrigerant tubes 16a and coolant tubes 43a are fixed, and a tank forming member 753. An upstream refrigerant space 733, an upstream coolant space 731 and a downstream refrigerant space 741 are formed inside the tank forming member 753 by fixing the tank forming member 753 to the header plate 751.

[0226]The upstream refrigerant space 733 and the upstream coolant space 731 are formed in an upstream tank portion 73. The upstream refrigerant space 733 collects or distributes refrigerant that flows through refrigerant tubes 16a of an upstream heat exchange portion 71. The upstream coolant space 731...

third embodiment

[0233]Next, a third embodiment of the present disclosure will be described with reference to FIG. 12. The third embodiment is different from the second embodiment in shape of header tank 75. FIG. 12 is a perspective sectional diagram showing a heat exchanger 70 of the third embodiment.

[0234]As shown in FIG. 12, a tank forming member 753 of a header tank 75 of the present embodiment is formed by extrusion molding. An upstream coolant space 731, an upstream refrigerant space 733 and a downstream refrigerant space 741 are provided inside the tank forming member 753. A communication space 76 is provided between the tank forming member 753 and a header plate 751, and refrigerant tubes 16a of an upstream heat exchange portion 71 communicates with refrigerant tubes 16a of a downstream heat exchange portion 72 through the communication space 76.

[0235]The tank forming member 753 includes a first communication hole 753a through which the upstream refrigerant space 733 communicates with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com