Spring-loaded geared flap structure

a technology of spring-loaded flaps and stabilizers, which is applied in the direction of vessel construction, special-purpose vessels, vessel movement reduction by foils, etc., can solve the problem that there is no other flap rudder that is spring-loaded, and achieve the effect of more certain and safer ship operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

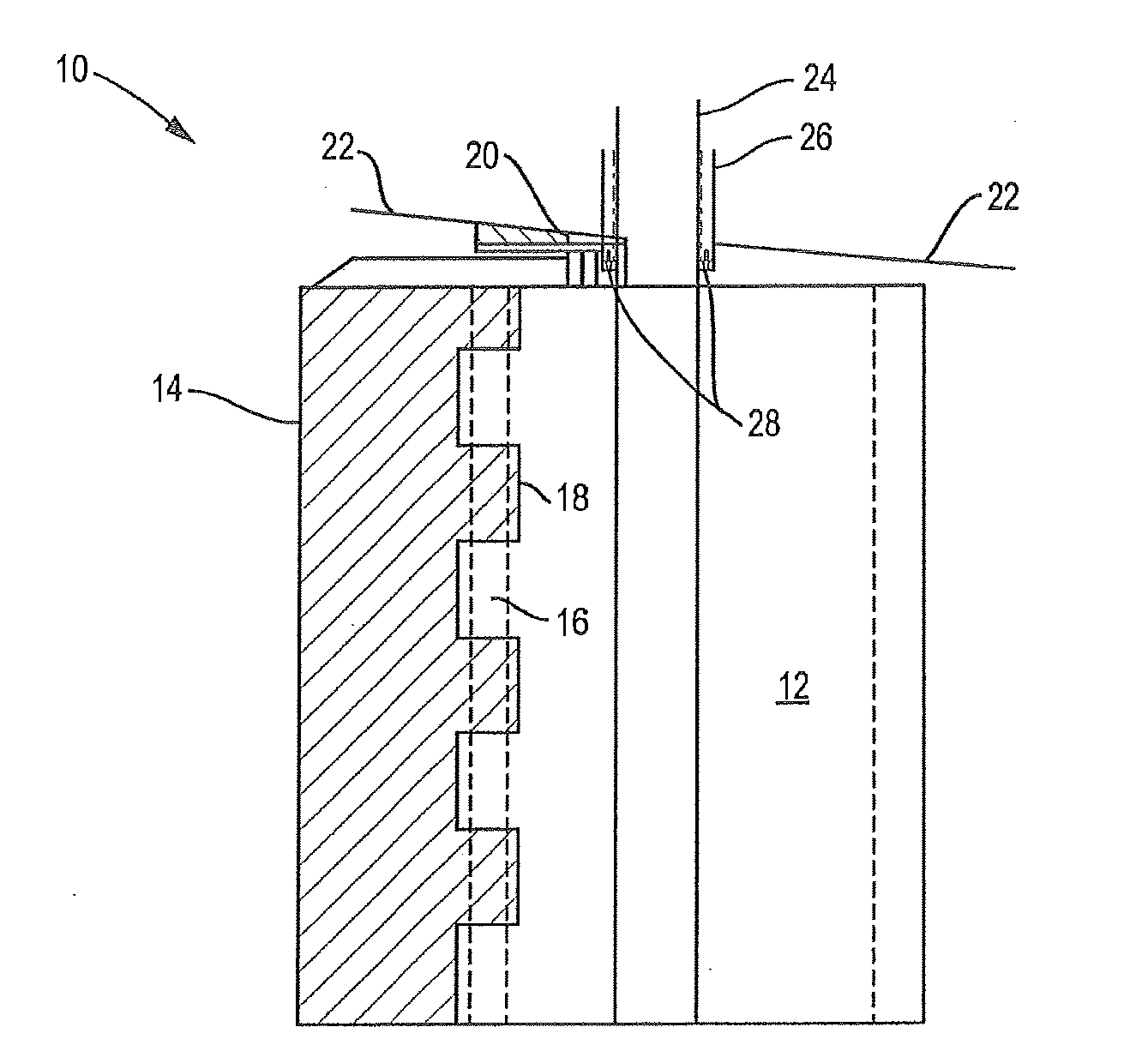

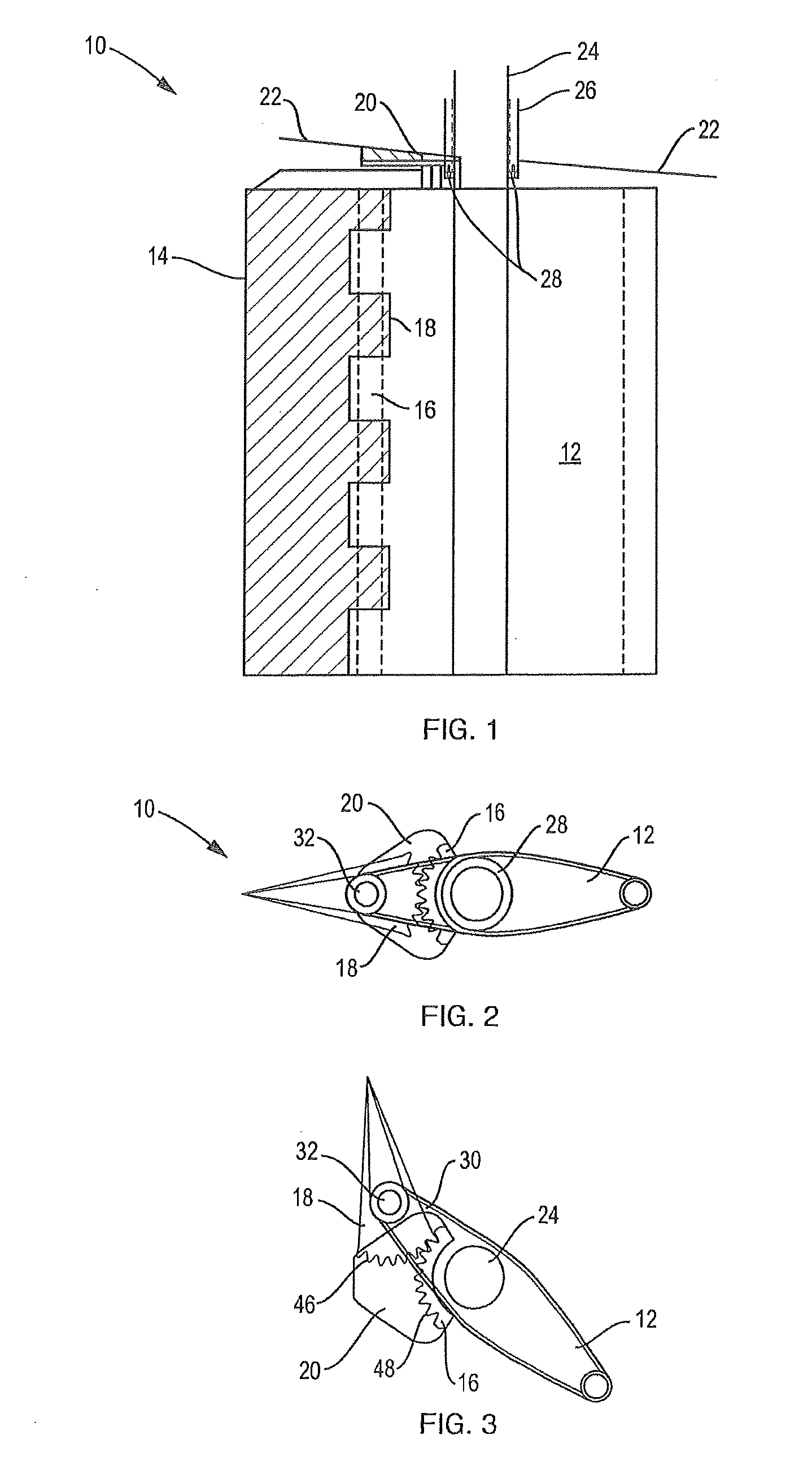

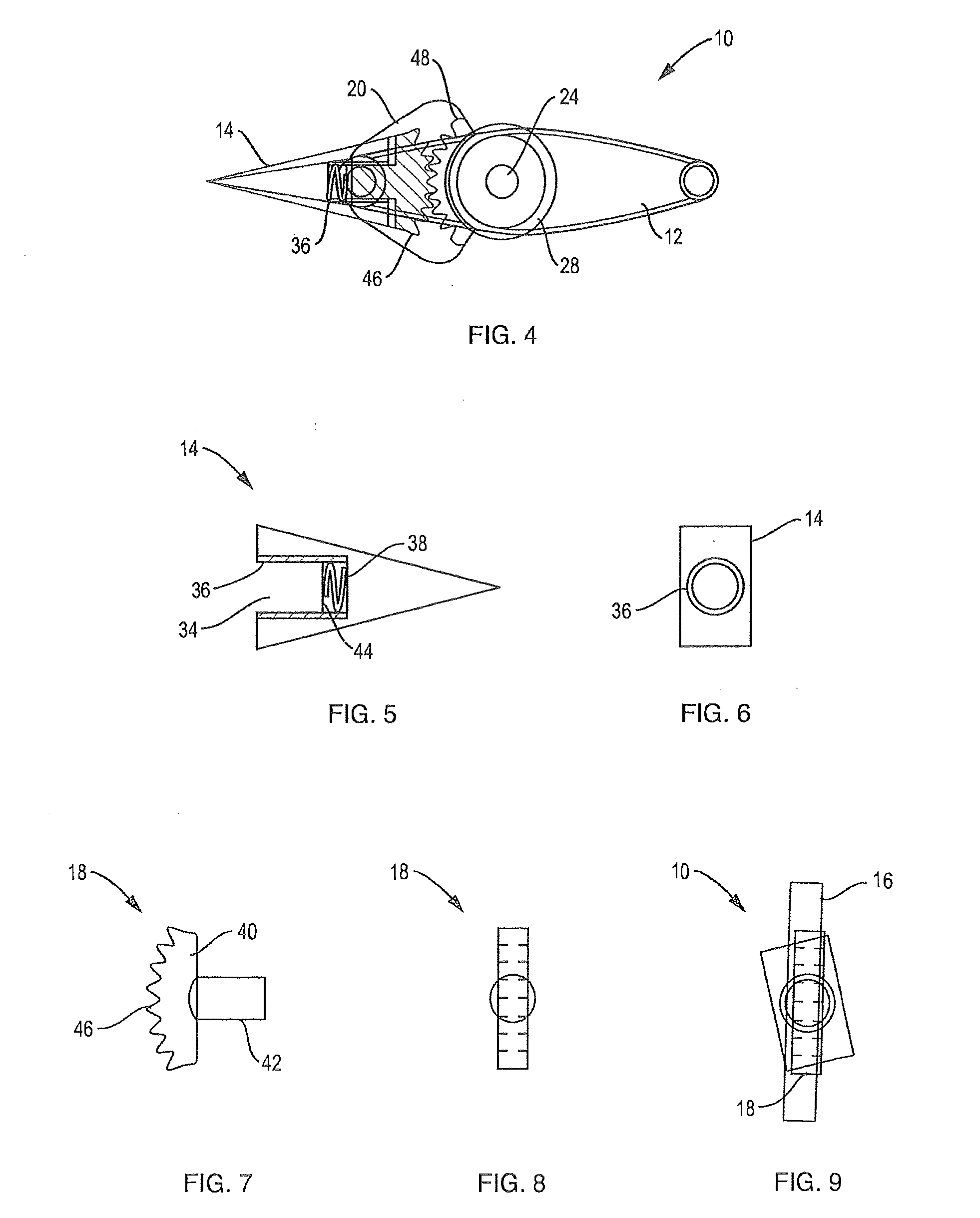

[0022]A spring-loaded geared flap rudder 10 of the present invention is shown in FIGS. 1-4. The flap rudder 10 includes a rudder member 12, a flap member 14, a rudder gear 16, a flap gear 18 and a gear cover 20. The flap rudder 10 is connected to a hull structure 22 of a ship aft of a propeller. Specifically, a rudder stock 24 of the rudder member 12 passes through a rudder port 26 of the hull structure 22 into an interior portion of the ship and joined to couplings and gearing controlled to cause movement of the rudder member 12. The rudder member 12 to hull 22 interface is sealed, such as with a split-ring seal 28, for example.

[0023]The rudder member 12 is rotatably mounted on the hull structure 20 by the rudder stock 24 such that the rudder member 12 is suspended from the hull structure 22. The flap member 14 is pivotally mounted on a trailing edge 30 of the rudder member 12 by way of a pivot rod 32.

[0024]The rudder gear 16 is connected to the hull structure 22, such as by weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com