Fin Spacing On An Evaporative Atmospheric Water Condenser

a technology of evaporative atmospheric water condensers and fin spacing, which is applied in the direction of ice removal, heat exhanger fins, lighting and heating apparatus, etc. it can solve the problems of insufficient heat transfer, affecting the effectiveness of coils, and water layers closest to the coils may freez

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

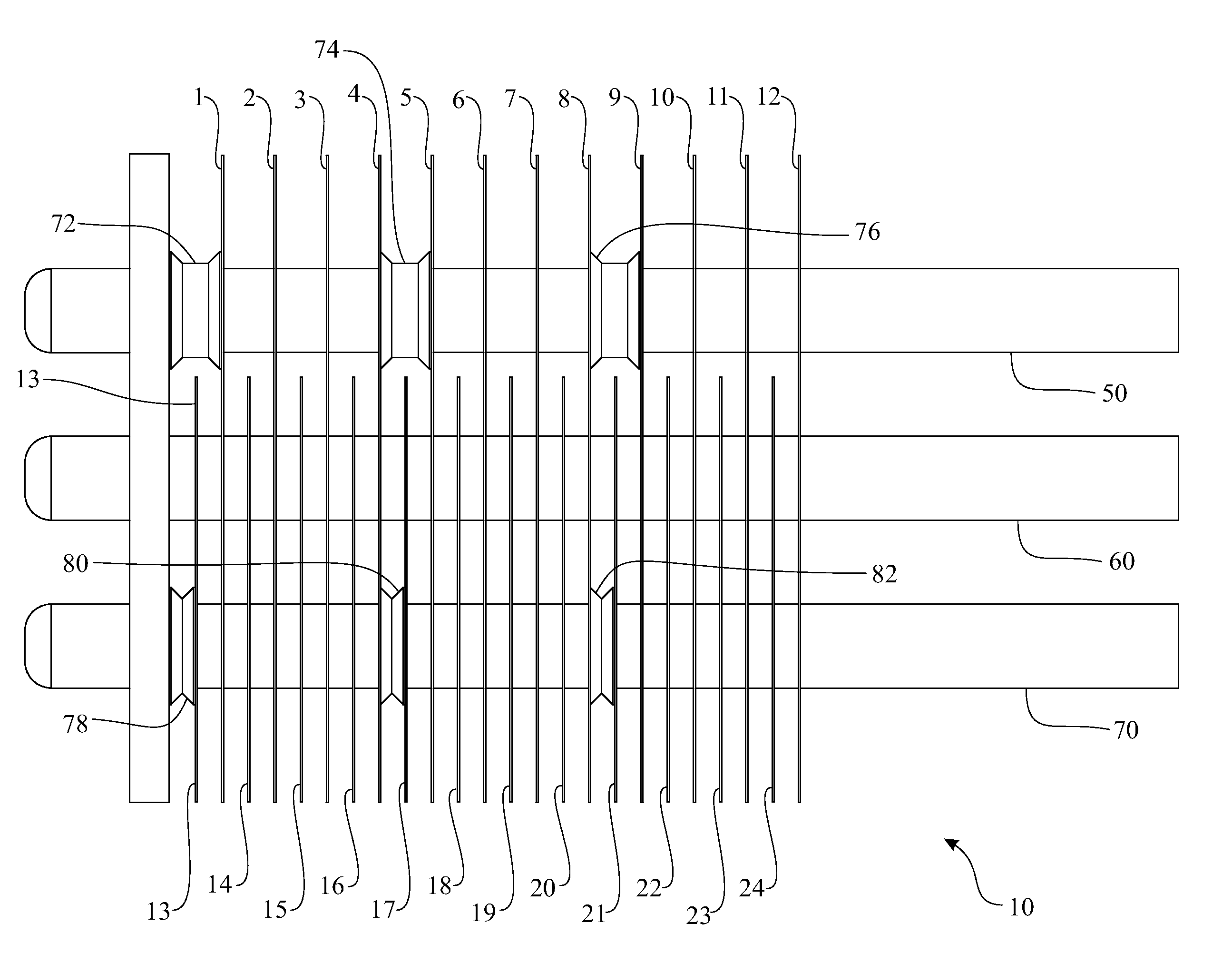

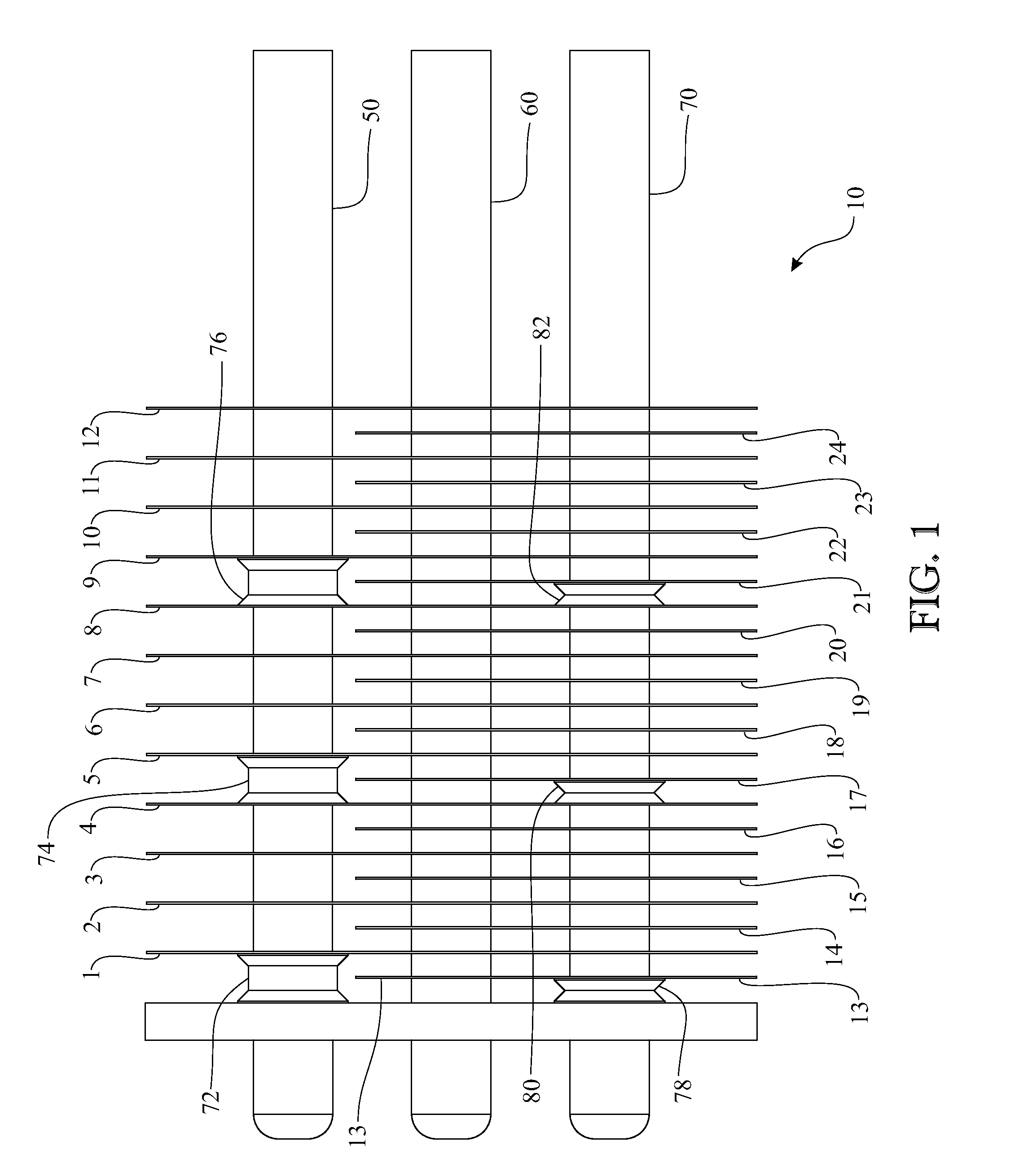

[0019]Referring to FIG. 1, a view of a three column coil evaporator for a water generating apparatus 10 is shown. There are three serpentine refrigerant coils in which the refrigerant enters on the right and flows downward to three refrigerant exits (best seen in FIG. 3). The rear refrigerant coil 50, the center refrigerant coil 60 and the front refrigerant coil 70 are shown from the bottom of FIG. 1. Initially, as the refrigerant enters the rear refrigerant coil 50, the center refrigerant coil 60 and the front refrigerant coil 70, it is in its coldest condition. Finally, as the refrigerant exits the rear refrigerant coil 50, the center refrigerant coil 60 and the front refrigerant coil 70, it is in its warmest condition. Conventional methods are employed to cool the refrigerant in these closed loop refrigerant coils.

[0020]Surrounding the rear refrigerant coil 50, the center refrigerant coil 60 and the front refrigerant coil 70 is a plurality of fins, individually numbered fin eleme...

second embodiment

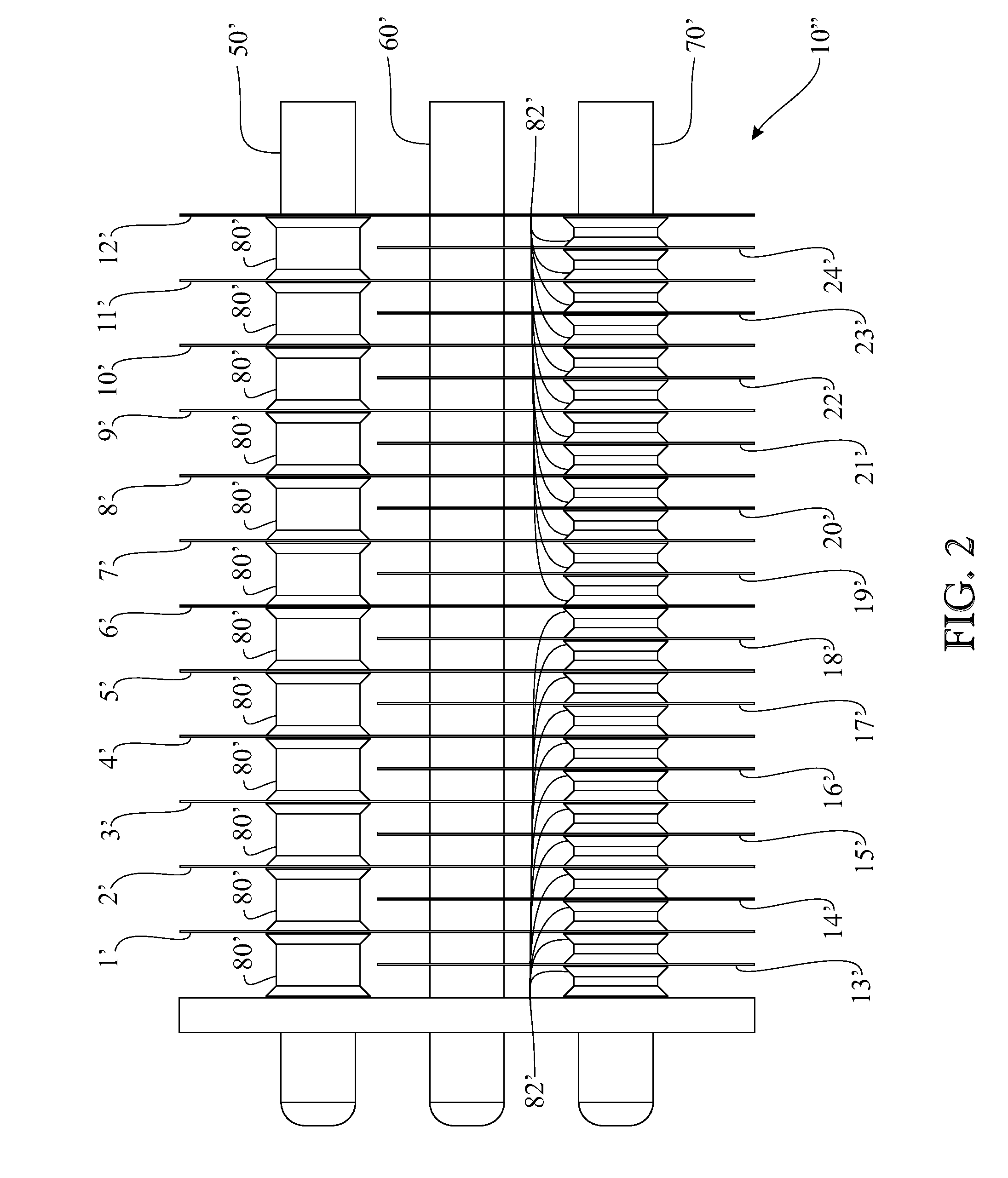

[0037]Referring to FIG. 2, a view of a three column coil evaporator for a water generating apparatus 10′ is shown. In this embodiment the top refrigerant coil 50′, the center refrigerant coil 60′ and the bottom refrigerant coil 70′ are shown. In this embodiment the top refrigerant coil 50′ has twelve spacers 80′ placed along its length. Additionally, the bottom refrigerant coil 70′ has twenty-four spacers 82′ placed along its length.

[0038]Except for the leftmost spacer 80′ on rear refrigerant coil 50′ each pair of spacers 80′ has a fin of the configuration of group 1 intermediately located. At the intersection of each spacer 80′ a fin element is located. Referring to the top refrigerant coil 50′, fins 1′-12′ are intermediate each of the spacers 80′ and each fin selected from the fins of the configuration of group 1. The three refrigerant coils (50′, 60′, 70′) have fins 1′-12′ mounted thereon, each spaced the width of one of the spacers 80′.

[0039]Similarly to the embodiment shown in ...

third embodiment

[0044]Referring now to FIG. 4, a view of a three column coil evaporator of a water generating apparatus 200 is shown. A first set of wider spacers 215 are placed on the rear refrigerant coil 210. A second set of smaller width spacers 222 are placed on the center refrigerant coil 220. A third set of the same smaller width spacers 232 are placed on the front refrigerant coil 230. The second set of smaller width spacers 222 are essentially the same width as the third set of smaller width spacers 232.

[0045]The rear refrigerant coil 210 shows twelve spacers 215. The spacers 215 are of equal width. These spacers 215 are not limited to twelve and would extend the length of the horizontal portion of the rear refrigerant coil 215.

[0046]The center refrigerant coil 220 shows twenty-four smaller spacers 222. The smaller spacers 222 are of equal width. These smaller spacers 222 are about ½ the width of the larger spacers 215.

[0047]The front refrigerant coil 230 includes twenty-four smaller space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com