Copper electroplating apparatus

a technology of copper electroplating and copper plate, which is applied in the direction of electrolysis process, semiconductor devices, electrolysis components, etc., can solve the problems of substrate damage, difficult to produce firm black film in a manner, and inability to permeate non-ionic organic additives, etc., and achieves uniform thickness and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]Embodiments of the present invention will now be described with reference to the drawings. The same reference numerals are used in the following figures and description to refer to the same or like members, components, etc., and a duplicate description thereof will be omitted.

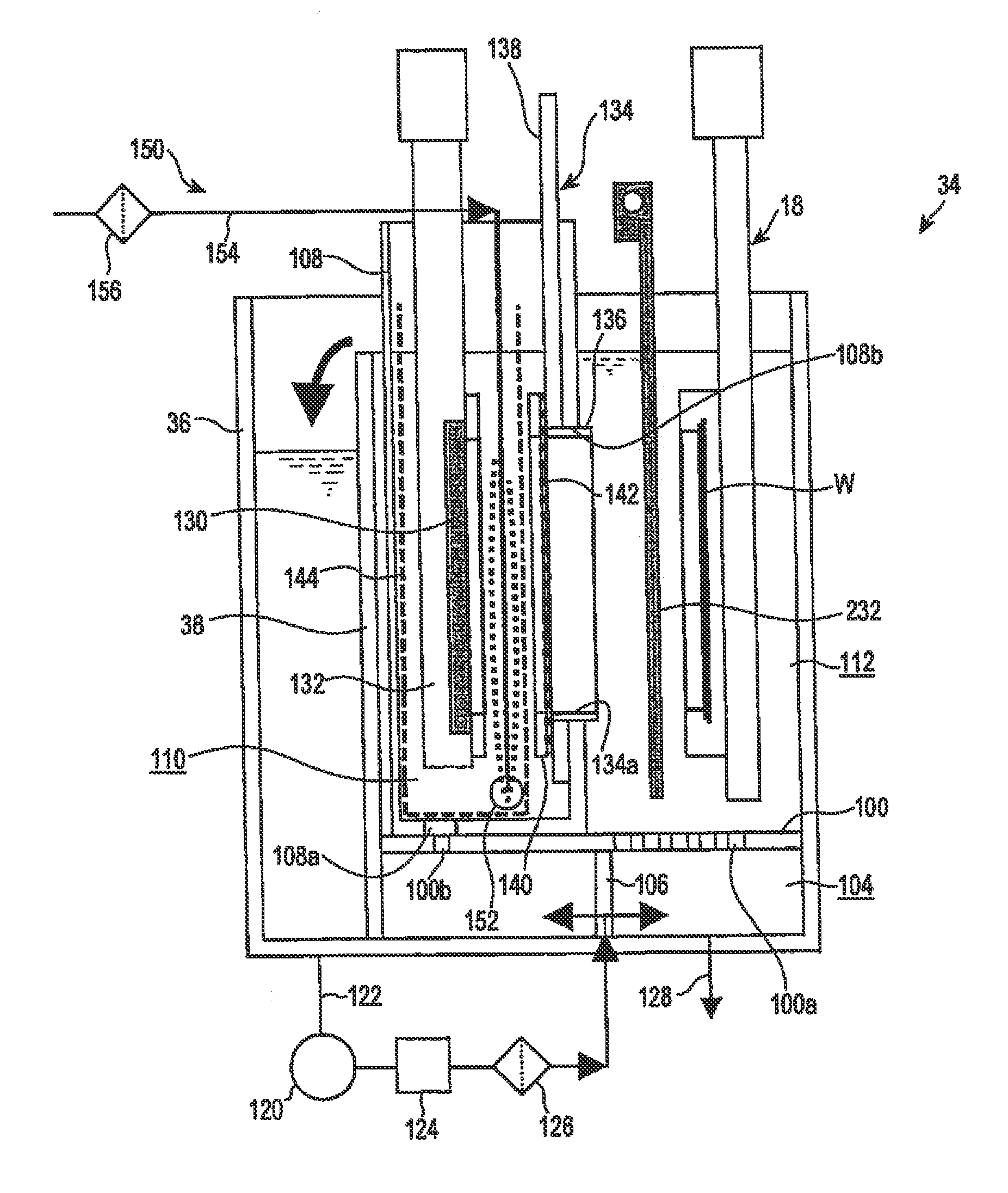

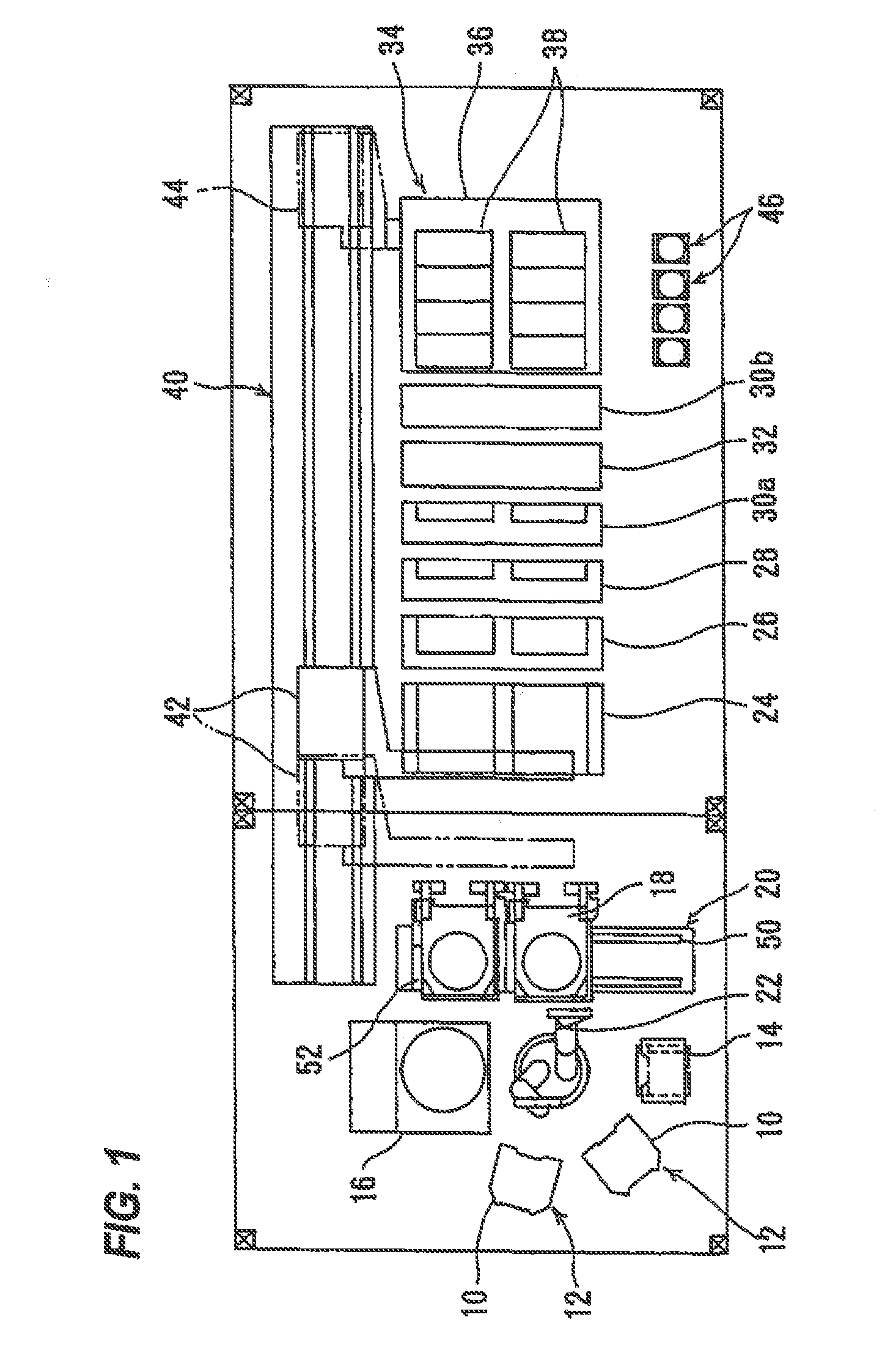

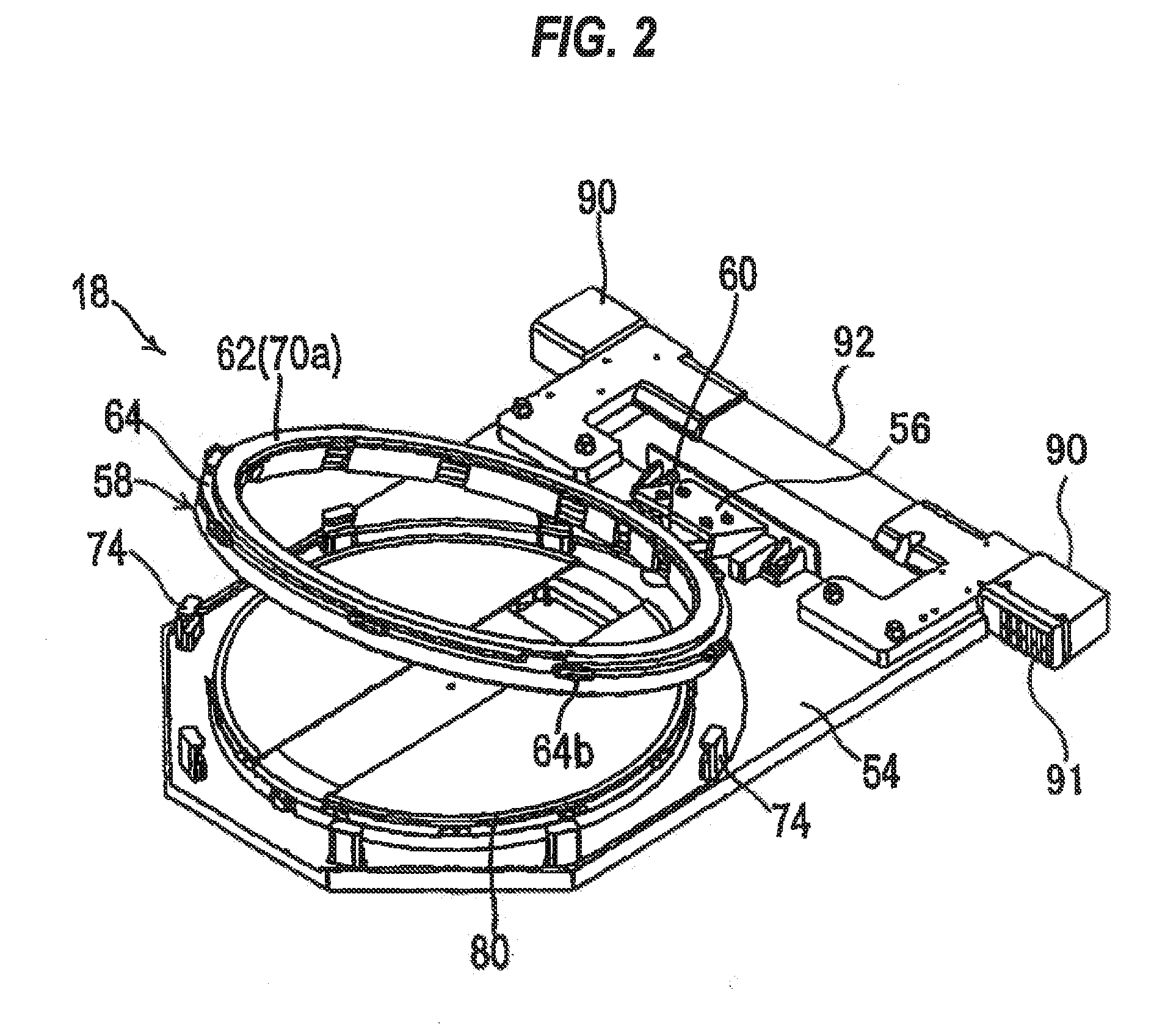

[0037]FIG. 1 shows an overall layout plan of a copper electroplating apparatus according to an embodiment. As shown in FIG. 1, the copper electroplating apparatus includes two cassette tables 12 on which substrate cassettes 10, each storing therein substrates, such as semiconductor wafers, are placed, an aligner 14 for aligning an orientation flat or a notch of a substrate in a predetermined direction, and a spin rinse drier 16 for drying a plated substrate by rotating it at a high speed. Near the spin rinse drier 16 is provided a substrate loading unit 20 for placing a substrate holder 18 thereon and loading the substrate into the substrate holder 18 and removing the substrate from the substrate holder 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com