Oxy-boiler with steam assisted production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

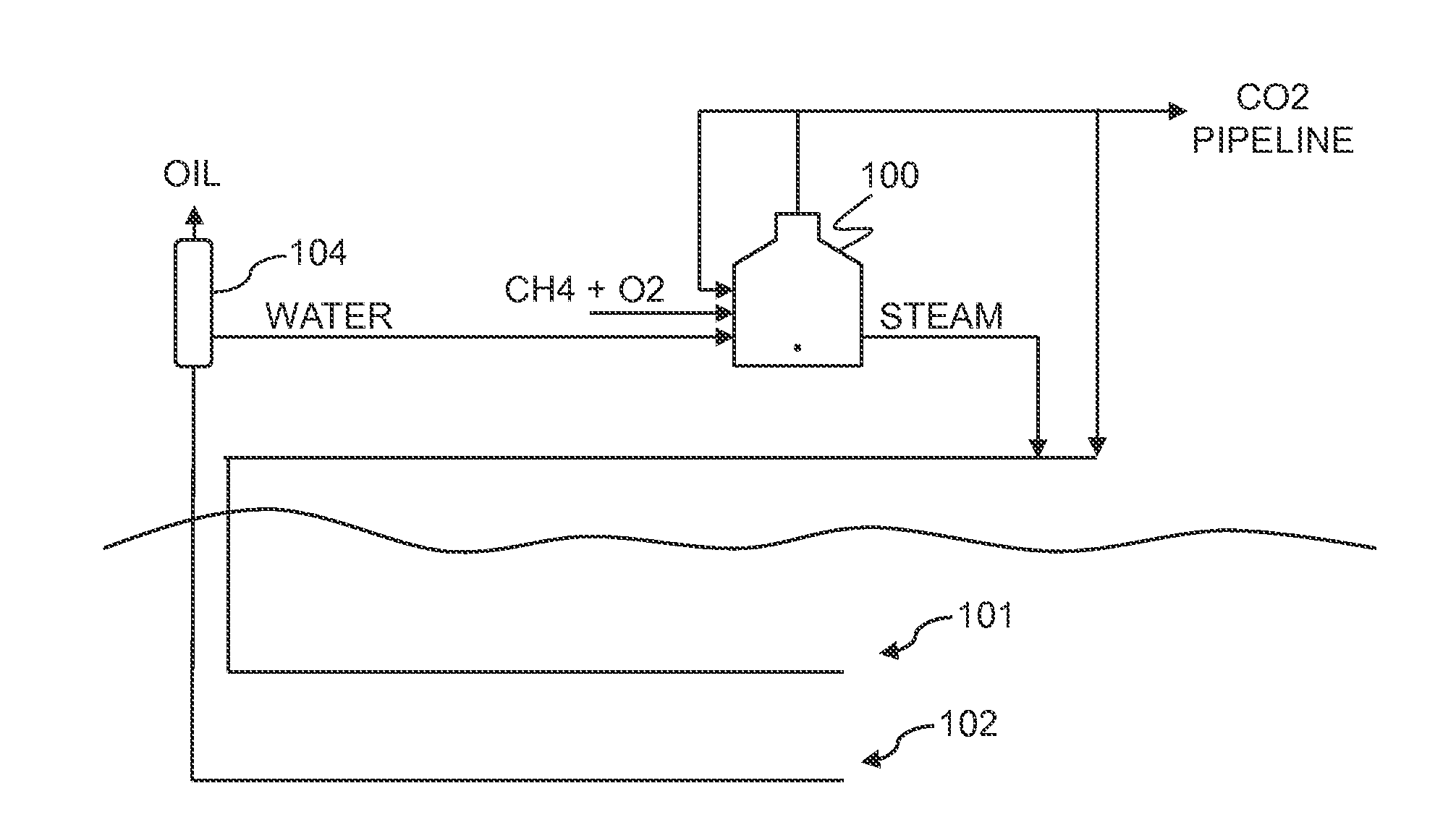

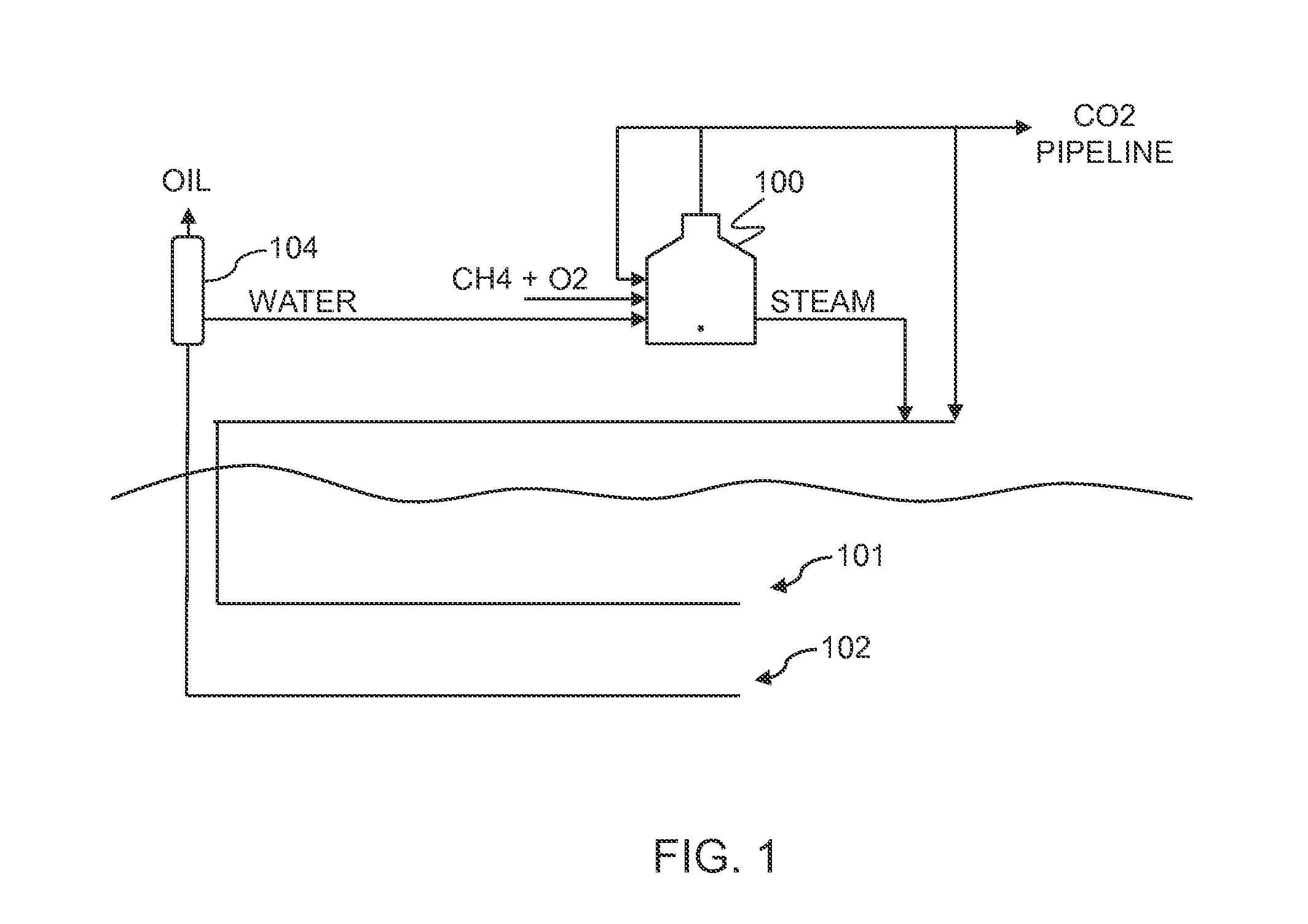

[0012]Turning now to the detailed description of the preferred arrangement or arrangements of the present invention, it should be understood that the inventive features and concepts may be manifested in other arrangements and that the scope of the invention is not limited to the embodiments described or illustrated. The scope of the invention is intended only to be limited by the scope of the claims that follow.

[0013]Methods and systems relate to an oxy-boiler used to generate steam injected into a well for assisting recovery of hydrocarbons. Operating conditions of a burner for the oxy-boiler limits oxygen contamination in a resulting flue gas for carbon dioxide recovery and limits size of the oxy-boiler, which may thus be located proximate the well rather at a central processing facility. In contrast to a direct steam generation approach where resulting carbon dioxide is mixed with steam, the oxy-boiler also enables selection of a desired level of carbon dioxide injection, which m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com