Cycloidal Pinwheel Pair with Uniform Contact and One-tooth Difference

a technology of cycloid pinwheel and uniform contact, which is applied in the direction of liquid fuel engines, machines/engines, rotary piston liquid engines, etc., can solve the problems of significant affecting the working stability of hydraulic equipment, reducing complex structure, so as to improve volume efficiency and mechanical efficiency, improve manufacturability, and improve the effect of volume efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

[0026 one:

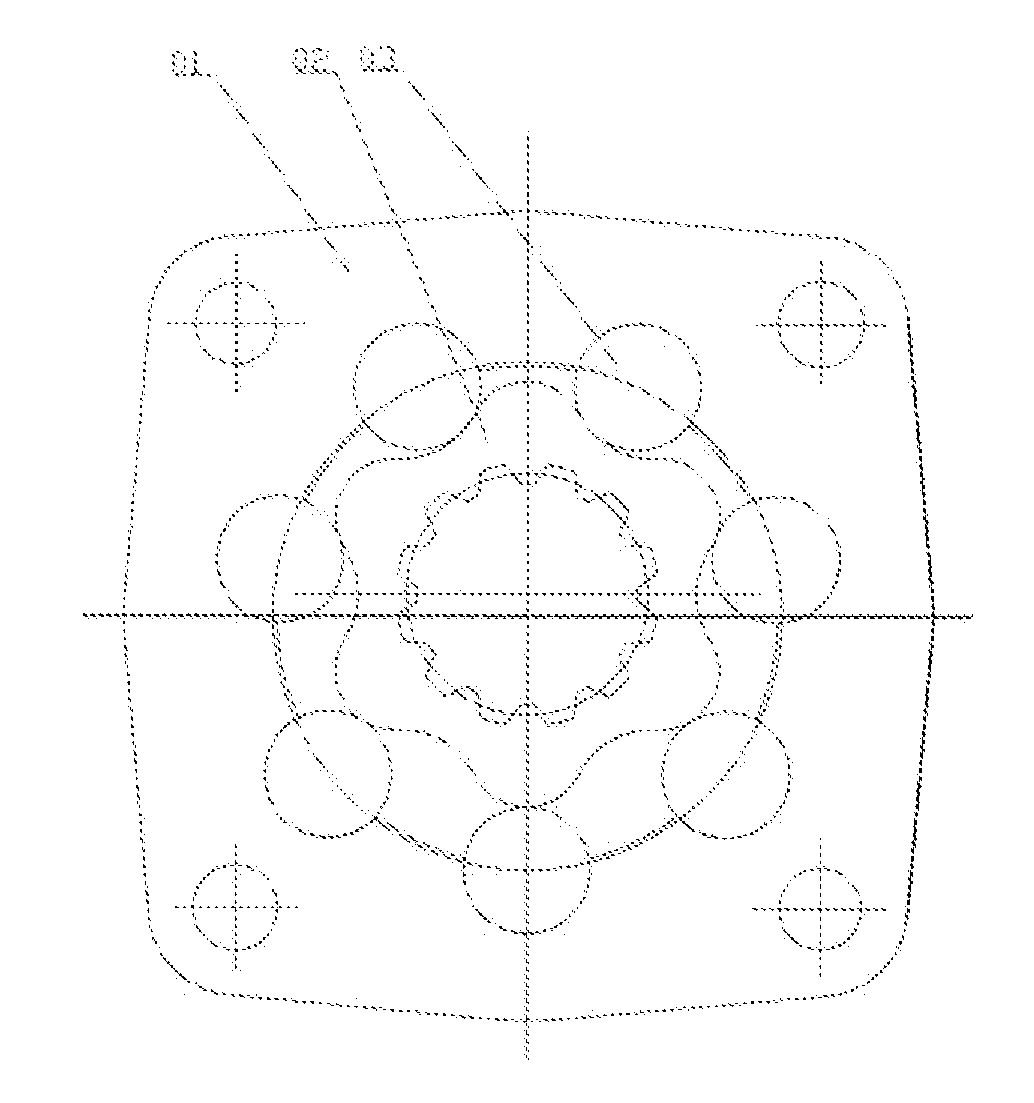

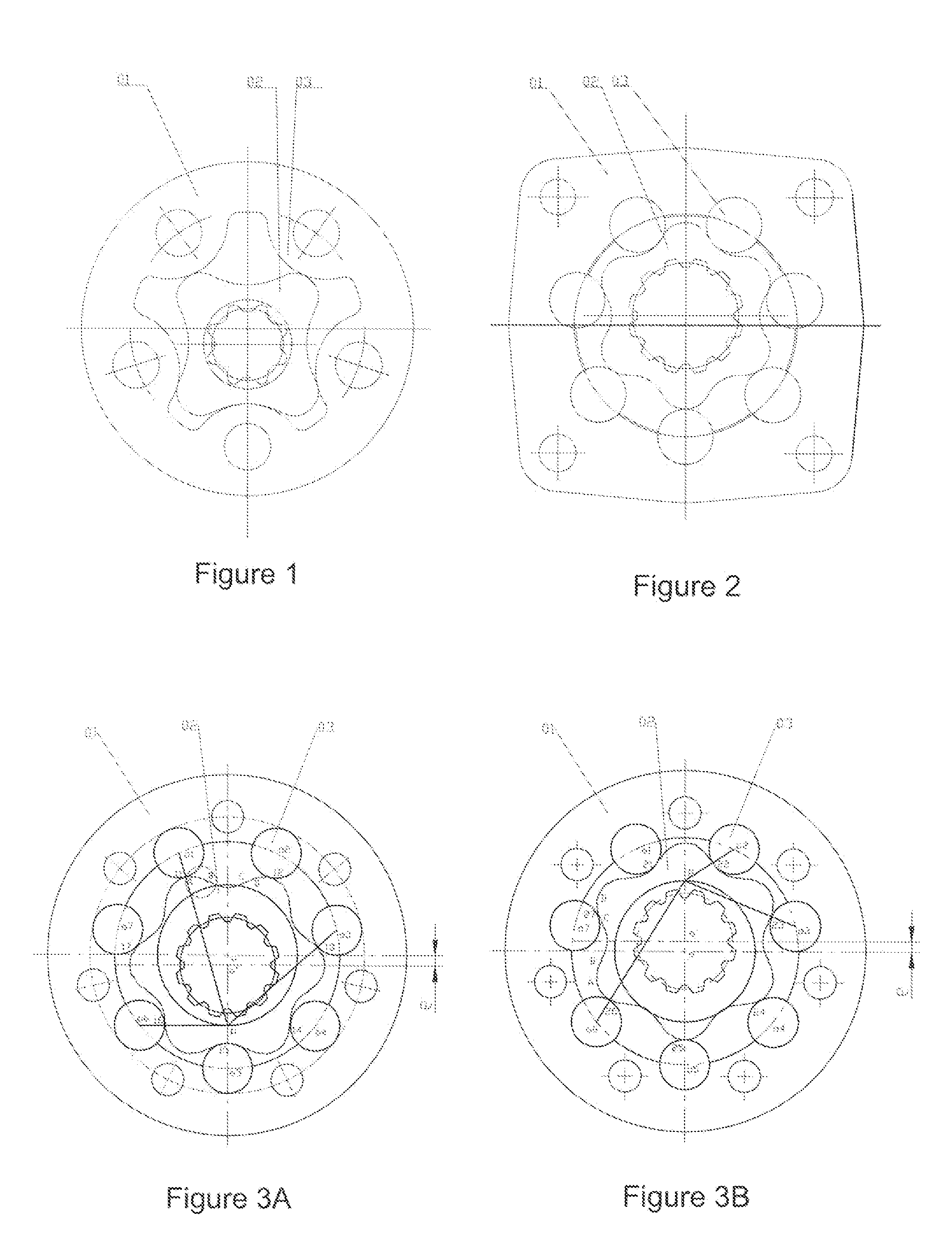

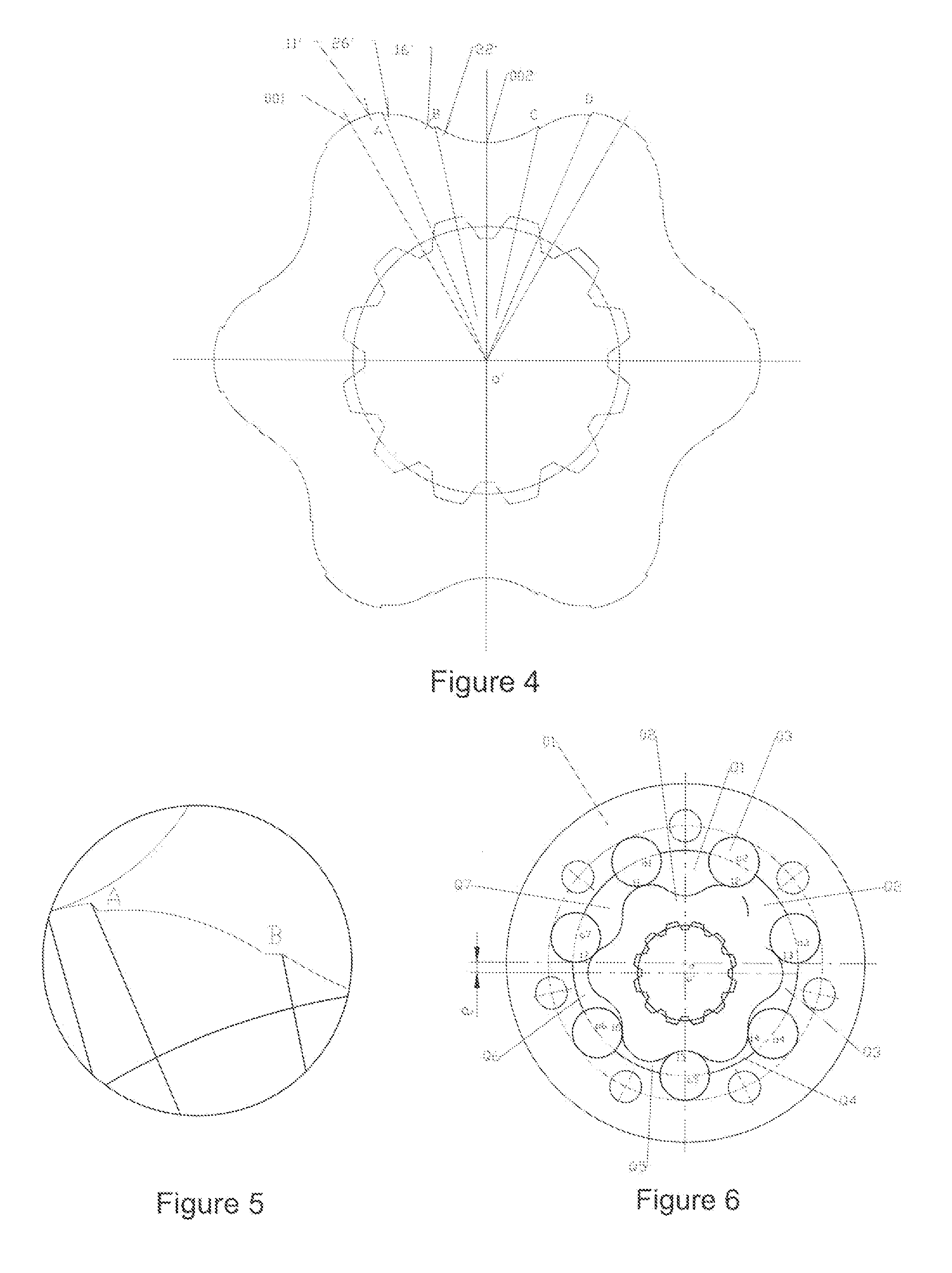

[0027]The structure of the cycloidal pinwheel pair with uniform contact and one-tooth difference according to embodiment one is as shown in FIG. 3A and FIG. 3B, including the stator 01 having seven pin teeth 03 in interval distribution, and the pinwheel rotor 02 having six gear teeth meshing with the stator, the centers of the seven pin teeth respectively are o1, o2, o3, o4, o5, o6 and o7. The meshing instant center P is the meshing pitch point formed by the rotor and the pin teeth, and is also the intersection point of the connection lines respectively formed between each of pin tooth centers o1, o2, o3, o4, o5, o6 and o7, and the respective meshing contact points 11, 12, 13, 14, 15, 16 and 17 of the gear teeth. Each gear tooth profile of the pinwheel rotor has a modified recess provided symmetrically on both sides (as shown in FIG. 4).

[0028]As shown in FIG. 4, the starting point A of the modified recess on one side of the gear tooth profile is located between the first p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com