Blade structure of axial fan

a blade structure and fan technology, applied in the direction of liquid fuel engines, vessel construction, marine propulsion, etc., can solve the problems of increasing the product cost of getting a higher air pressure, limiting success, etc., to achieve a greater air volume, higher air pressure, and improved static pressure and air flow rate characteristic. q curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]In cooperation with attached drawings, the technical contents and detailed description of the invention are described thereinafter according to a number of preferable embodiments, being not used to limit its executing scope. Any equivalent variation and modification made according to appended claims is all covered by the claims claimed by the present invention.

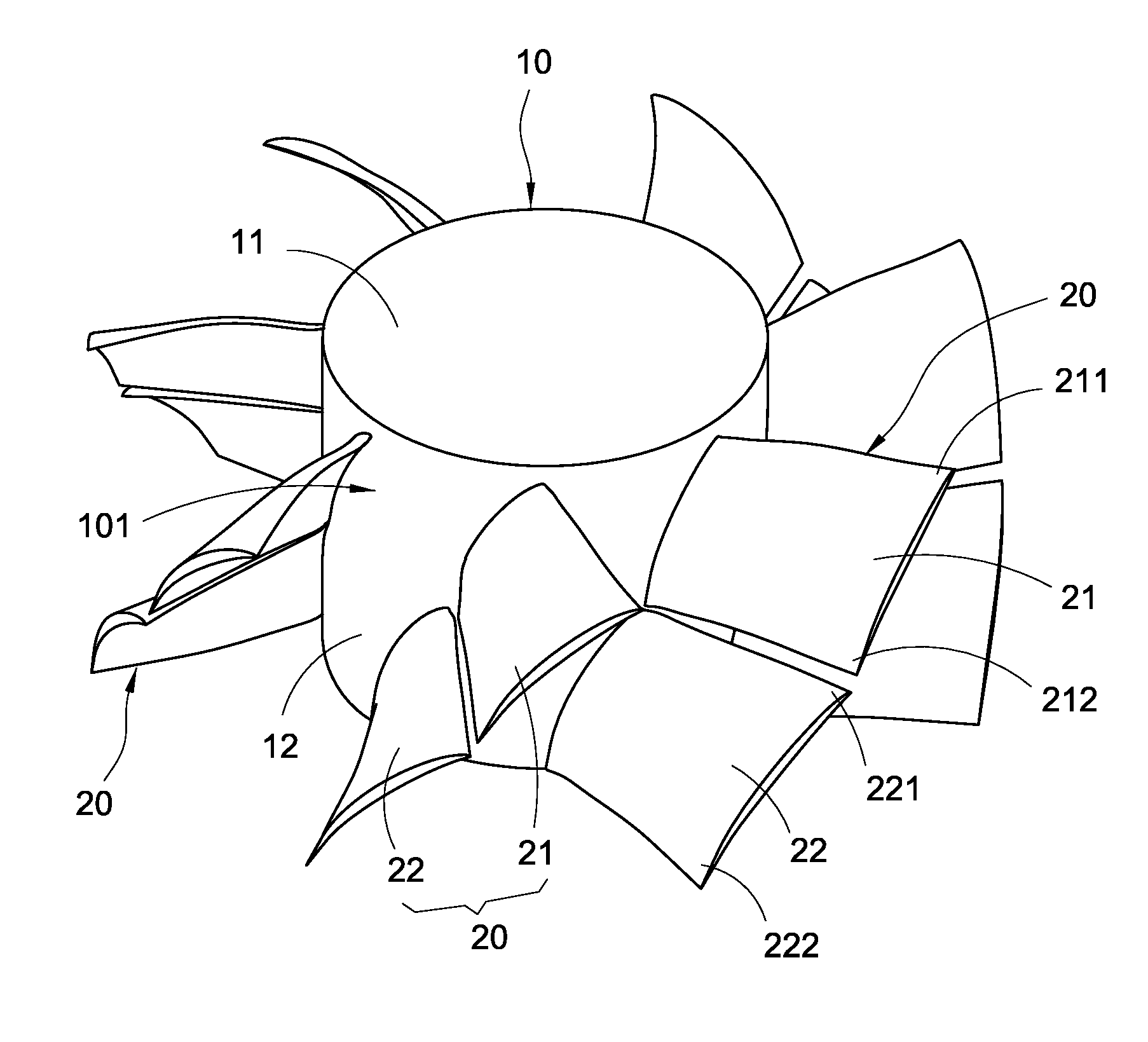

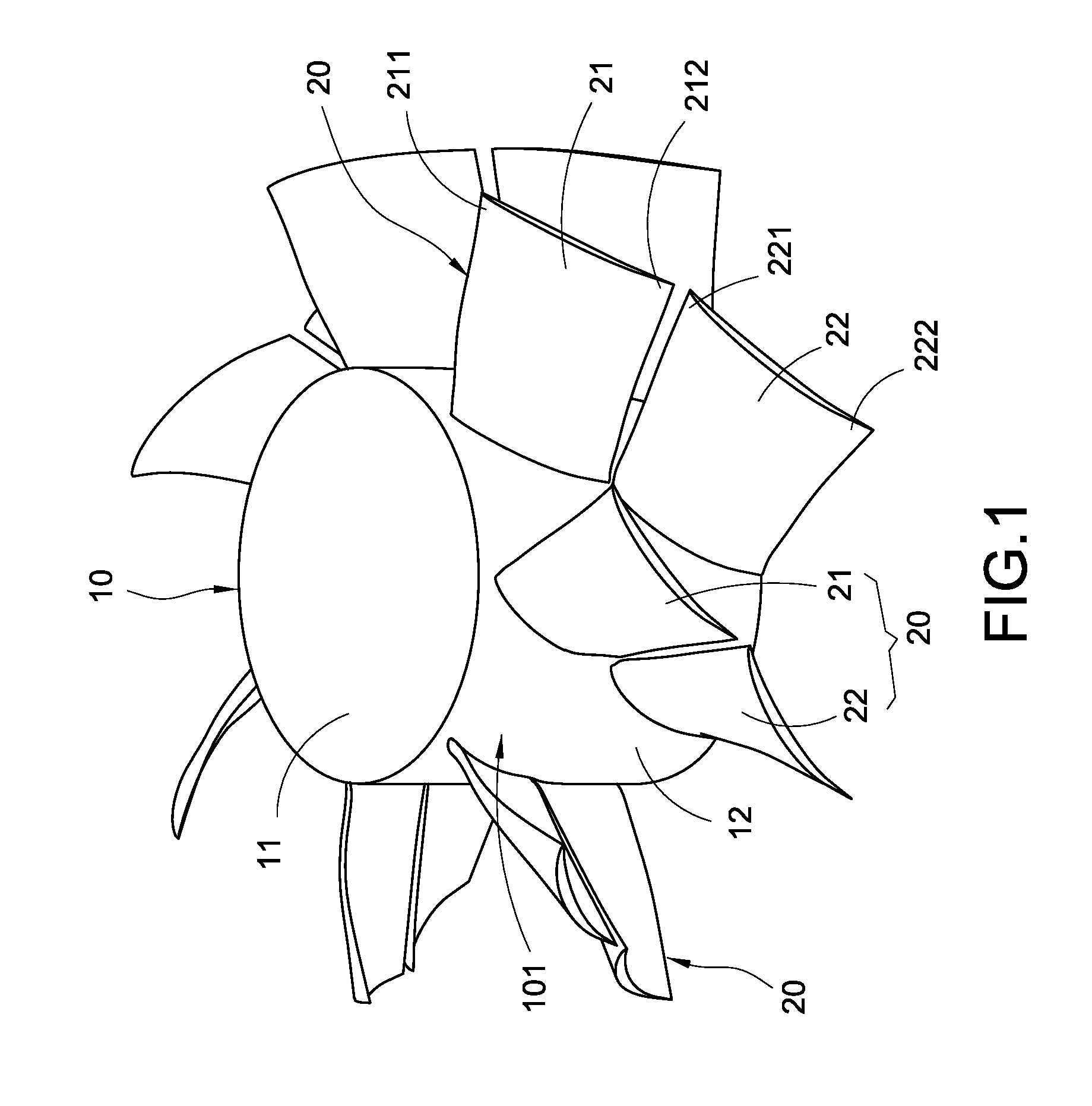

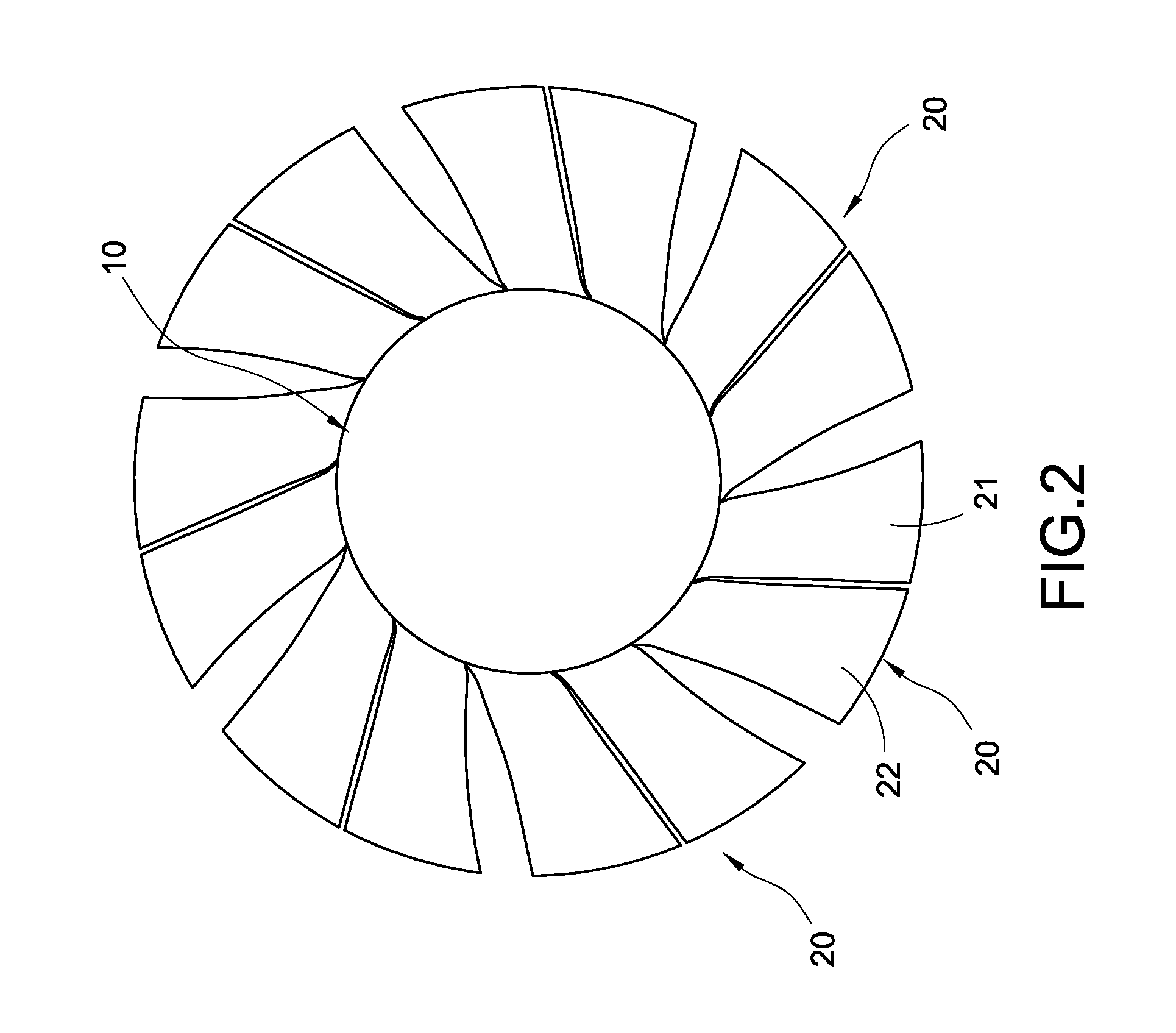

[0019]Please refer to FIG. 1 and FIG. 2, they depict a perspective schematic view and a top view of a blade structure of an axial fan of the present invention. The present invention provides a blade structure of an axial fan including a hub 10 and a plural of fan blades 20. The fan blades 20 are combined on the hub 10. The hub 10 is driven to rotate with the fan blades 20 to push surrounding fluid flowing.

[0020]The hub 19 is a cylinder including a top plate 11 and a side plate 12 extended from a periphery of the top plate 11, and the side plate 12 encloses one side of the top plate 11 for forming a peripheral surface 101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com