Heat dissipating fin and heat dissipating device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

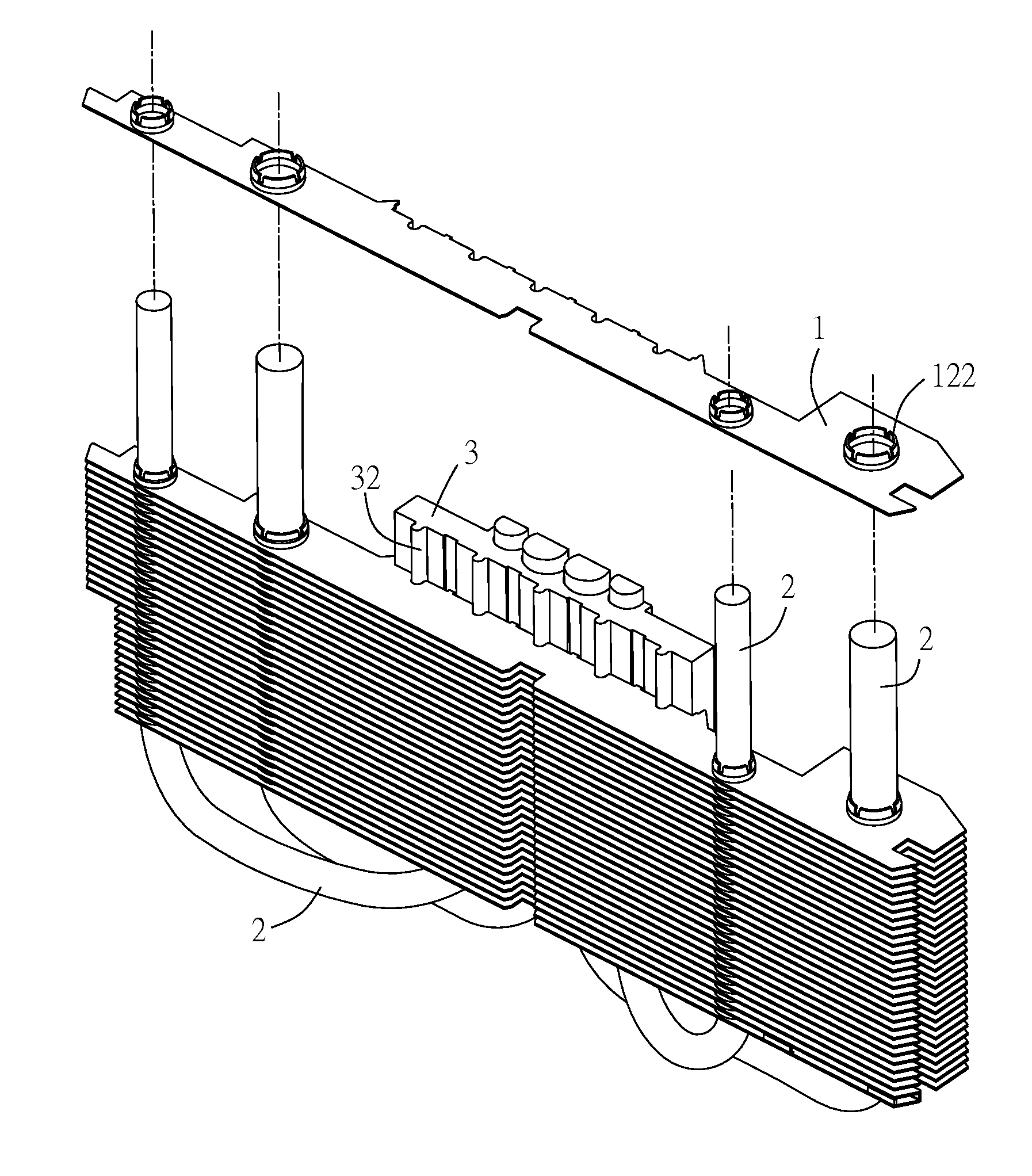

[0020]A heat dissipating fin and a heat dissipating device will be illustrated with relating drawings, and the same number donates the same component.

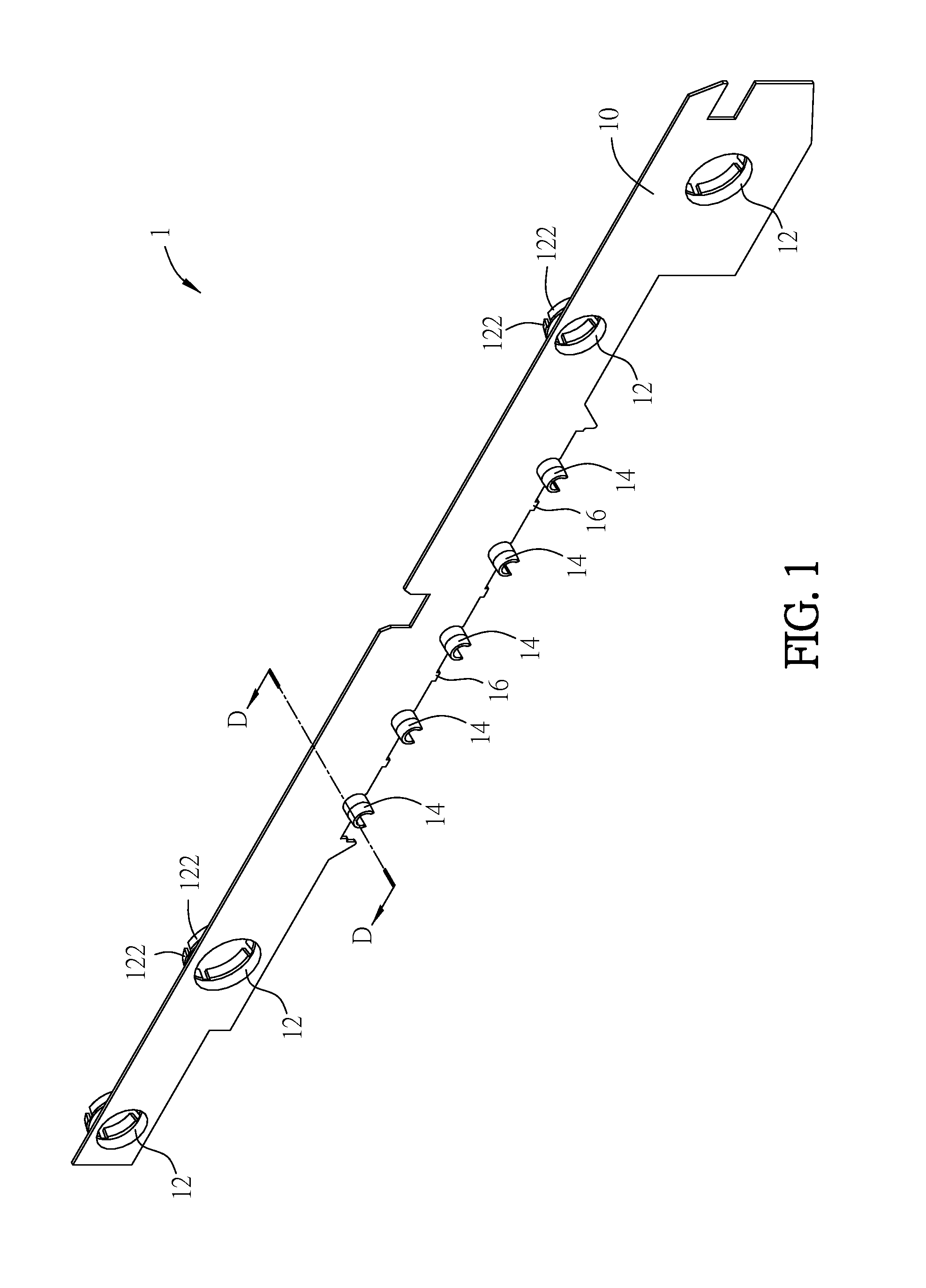

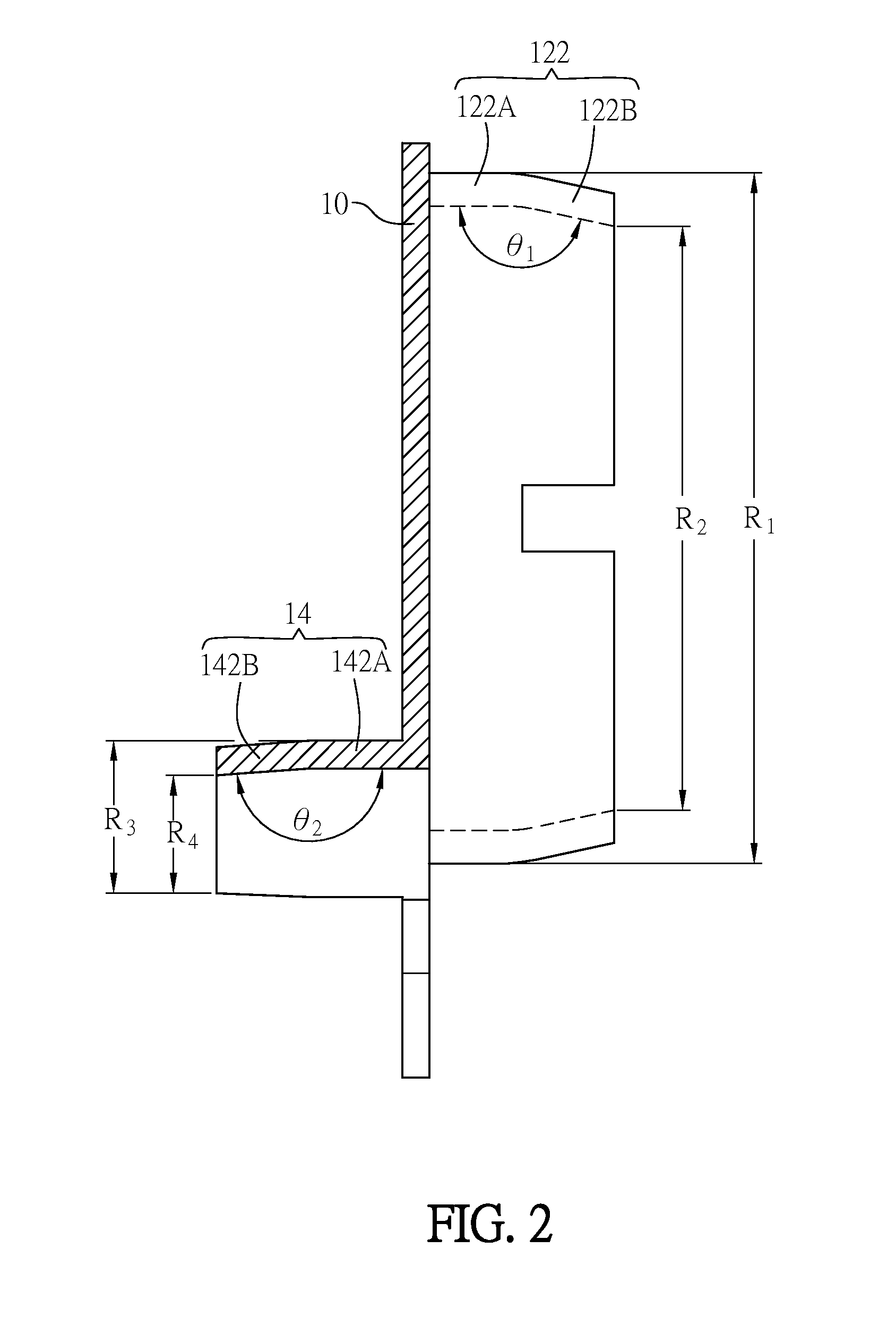

[0021]FIG. 1 is a schematic diagram showing a heat dissipating fin in an embodiment of the disclosure. FIG. 2 is a schematic diagram showing a cross section of the heat dissipating fin in FIG. 1 along the cross line DD. FIG. 3 is an enlarged view showing a through hole of the heat dissipating fin in FIG. 1.

[0022]In an embodiment, a heat dissipating fin 1 includes a main body 10 and at least a through hole 12 formed on the main body 10. In the embodiment, the number of the through hole 12 is four, however, the number of the through hole 12 is not a limitation herein. In an embodiment, the material of the heat dissipating fin 1 is aluminum, copper, aluminum alloy, copper alloy or copper aluminum alloy which is not limited herein.

[0023]Each through hole 12 at least includes two collar portions 122, each collar portion 122 forms on the edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com