Method for Producing at least One Component and Open-Loop and/or Closed-Loop Control Device

a control device and component technology, applied in the direction of liquid surface applicators, solid-state diffusion coatings, coatings, etc., can solve the problems of difficult diffusion of donor gases within the charge and/or within the interior geometries, such as blind hole bores, and the inability to ensure a continuous uptake of carbon and nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

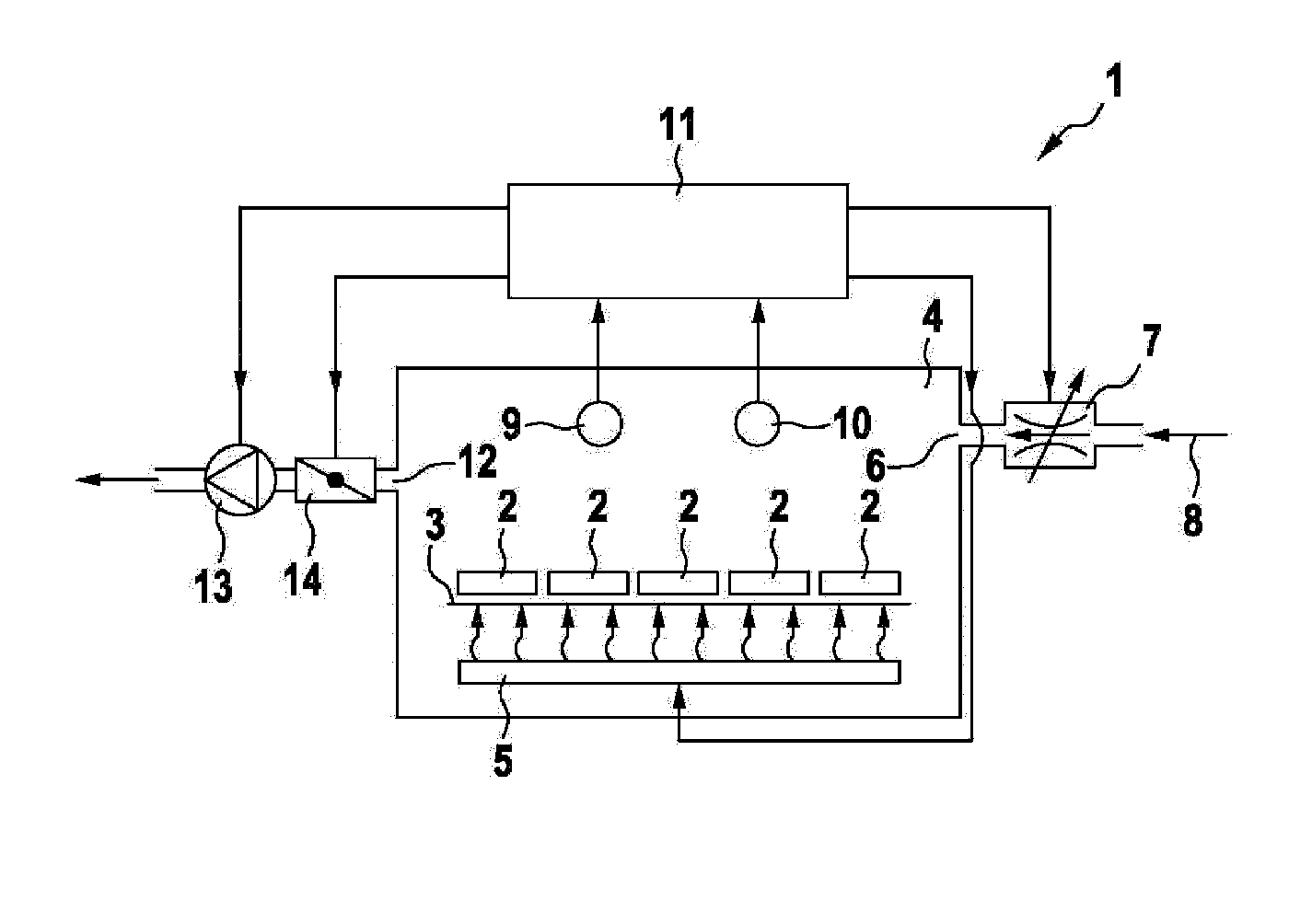

[0033]FIG. 1 shows a schematic representation of a plant 1 for the low-pressure carbonitriding of one or more components 2. In FIG. 1, five components 2 are represented by way of example. The components 2 are arranged on a support 3 in a treatment chamber 4. The components 2 can be heated by means of a heating device 5 represented in the lower region of the drawing. An inlet 6 with an associated flow control valve 7 allows the introduction of a carbon- and nitrogen-donor gas 8. A temperature sensor 9 and a pressure sensor 10 are arranged in the upper region of the drawing of the treatment chamber 4. An open-loop and / or closed-loop control device 11 shown above them receives the signals coming from the temperature sensor 9 and the pressure sensor 10. An outlet 12 of the treatment chamber 4 leads to the input of a pump 13, which may be formed for example as a vacuum pump. Arranged upstream of the pump 13 is a throttle 14, in particular for controlling the pressure.

[0034]During the ope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com