Esomeprazole magnesium enteric-coated pellets and capsules and preparation method thereof

A technology of esomeprazole magnesium enteric-coated pellets and esomeprazole magnesium, which is applied in capsule delivery, pill delivery, pharmaceutical formulations, etc., and can solve problems such as unsatisfactory effects of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

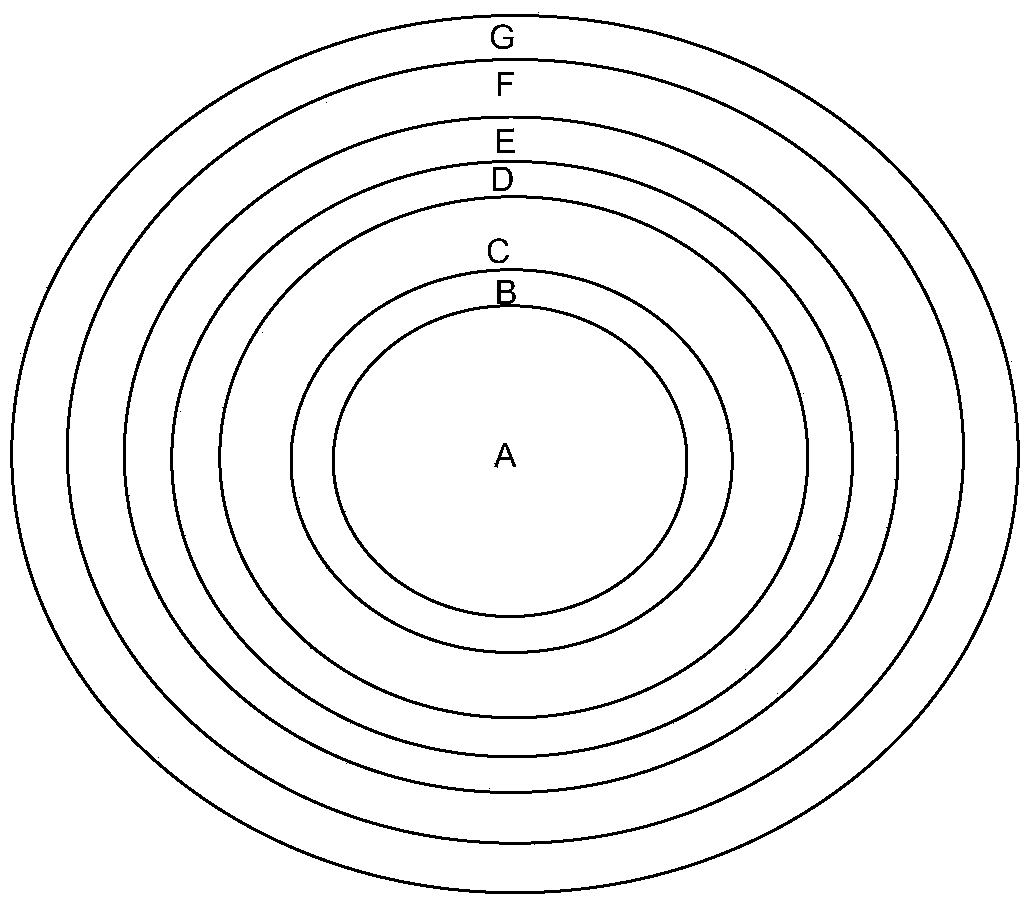

Image

Examples

preparation example Construction

[0080] The preparation method of esomeprazole magnesium enteric-coated pellets is as follows:

[0081] ⑴Isolation gown layer

[0082] Purpose: To isolate the sugar pill from the active ingredient layer, so that the surface of the sugar pill is smoother and rounder.

[0083] prescription:

[0084]

[0085] Preparation process: ① Weigh purified water and pour it into a container, add the above three auxiliary materials while stirring, and stir for 10-20 minutes to obtain a solution for later use.

[0086] ② Pour the medicinal pellet core into the bottom spray coating pot, set the inlet air temperature: 40-65°C, air volume:

[0087] 200-1500m 3 / h, control the liquid supply speed:

[0088] Spray liquid at 8-50rpm, dry, and increase the weight of the coating by 5%-12%.

[0089] ⑵ drug layer

[0090] Purpose: To coat the active ingredient layer.

[0091] prescription:

[0092]

[0093] Preparation process: ① Weigh purified water and pour it into a container, add esome...

Embodiment 1

[0123] Preparation of enteric-coated pellets of esomeprazole magnesium

[0124] ⑴Isolation gown layer

[0125] prescription:

[0126]

[0127] Preparation process: ① Weigh 4 kg of purified water and pour it into a container, add the above three auxiliary materials while stirring, and stir for 15 minutes to obtain a solution for later use.

[0128] ② Pour the medicinal pellet sugar core (sucrose core, 160μm average particle size) into the bottom spray coating pan, set the inlet air temperature: 40-65°C, air volume:

[0129] 800m 3 / h, control the liquid supply speed: spray liquid at 35rpm, dry, and the coating weight increases by 7.5%.

[0130] ⑵ drug layer

[0131] Purpose: To coat the active ingredient layer.

[0132] prescription:

[0133]

[0134] Preparation process: ① Weigh purified water and pour it into a container, add esomeprazole magnesium and the above two excipients while stirring, stir for 15 minutes, set aside,

[0135] ② Pour the dry coated product ...

Embodiment 2

[0164] The pellets and auxiliary materials obtained in Example 1 were mixed evenly, and compressed into tablets to prepare tablets.

[0165] prescription:

[0166]

[0167] Preparation process: Add esomeprazole magnesium enteric-coated pellets, microcrystalline cellulose, crospovidone, and polyethylene glycol into a three-dimensional mixer and mix for 15 minutes, then add magnesium stearate and mix for 5 minutes, and the Material, tablet. Made in different doses. That is, the dosage is that each tablet contains 20 mg and 40 mg of esomeprazole magnesium respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average layer thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com