Vibration-reducing structure for compressing diaphragm pump

a diaphragm pump and vibration-reducing technology, which is applied in the direction of pump control, pump components, positive displacement liquid engines, etc., can solve the problems of long-standing serious drawbacks of forgoing other parts of conventional compressing diaphragm pumps also shaking simultaneously, and the whole conventional compressing diaphragm pump vibrates directly, etc., to achieve shorten the length of the moment arm, reduce the torque, and reduce the torqu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

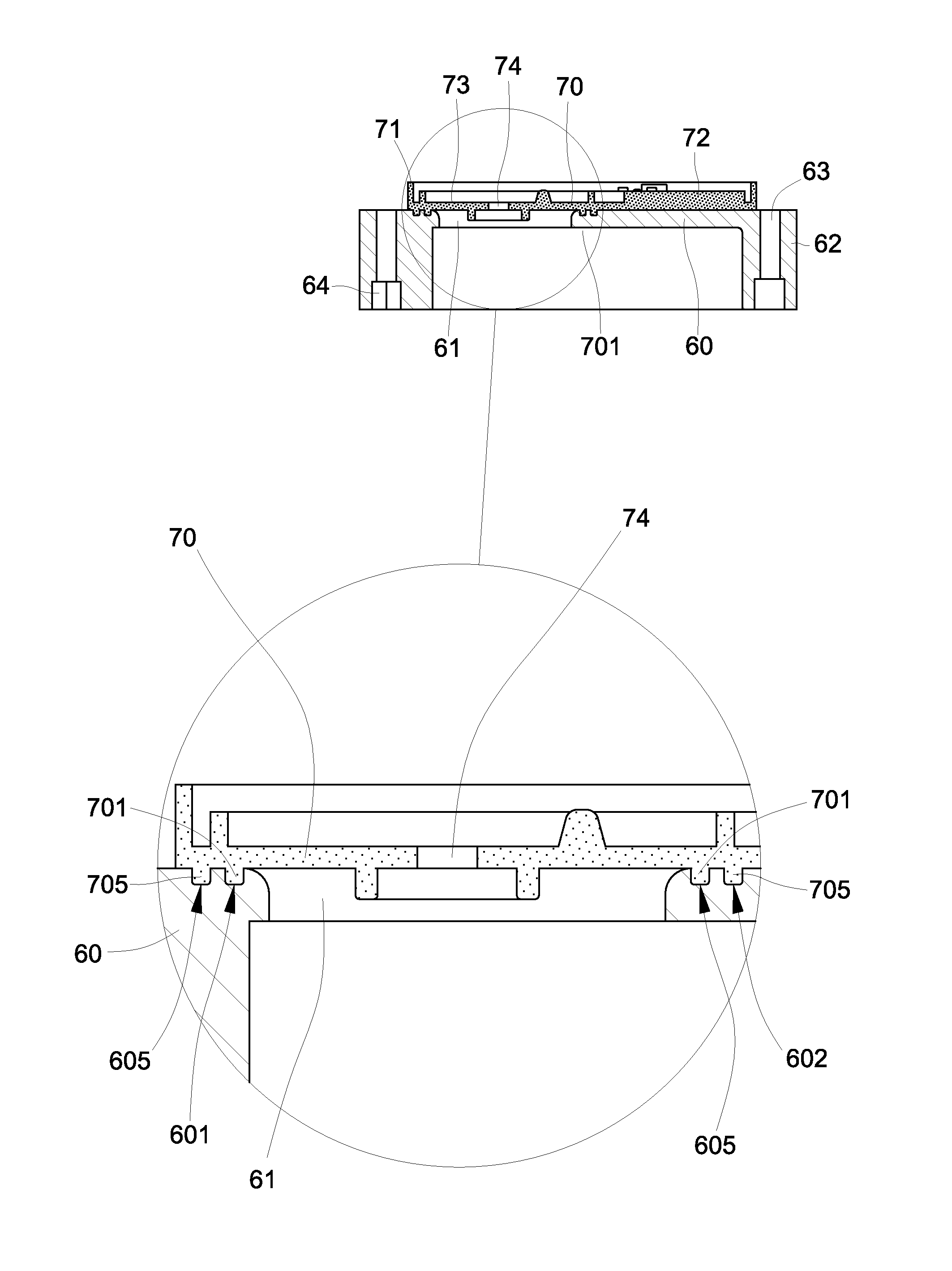

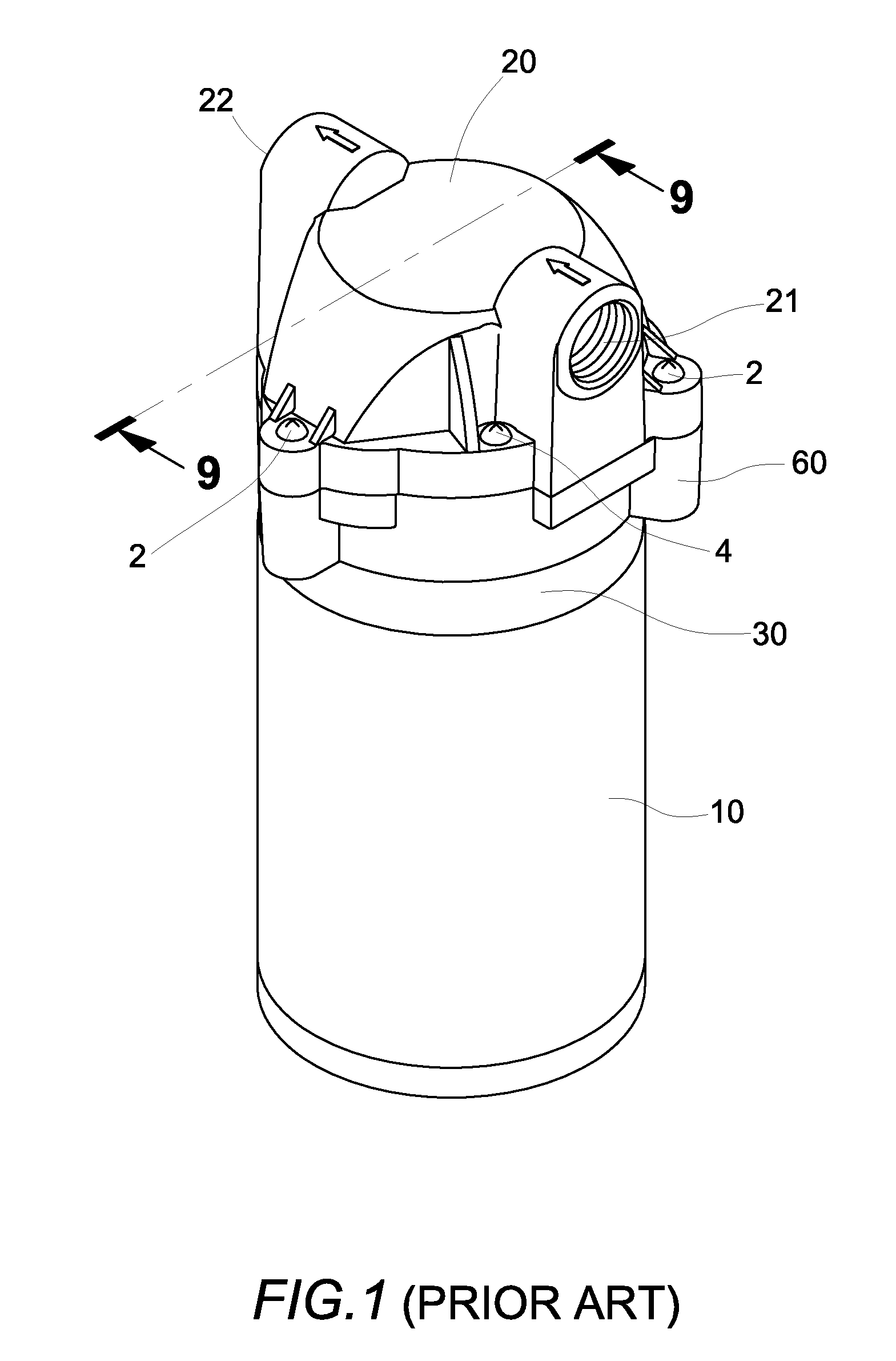

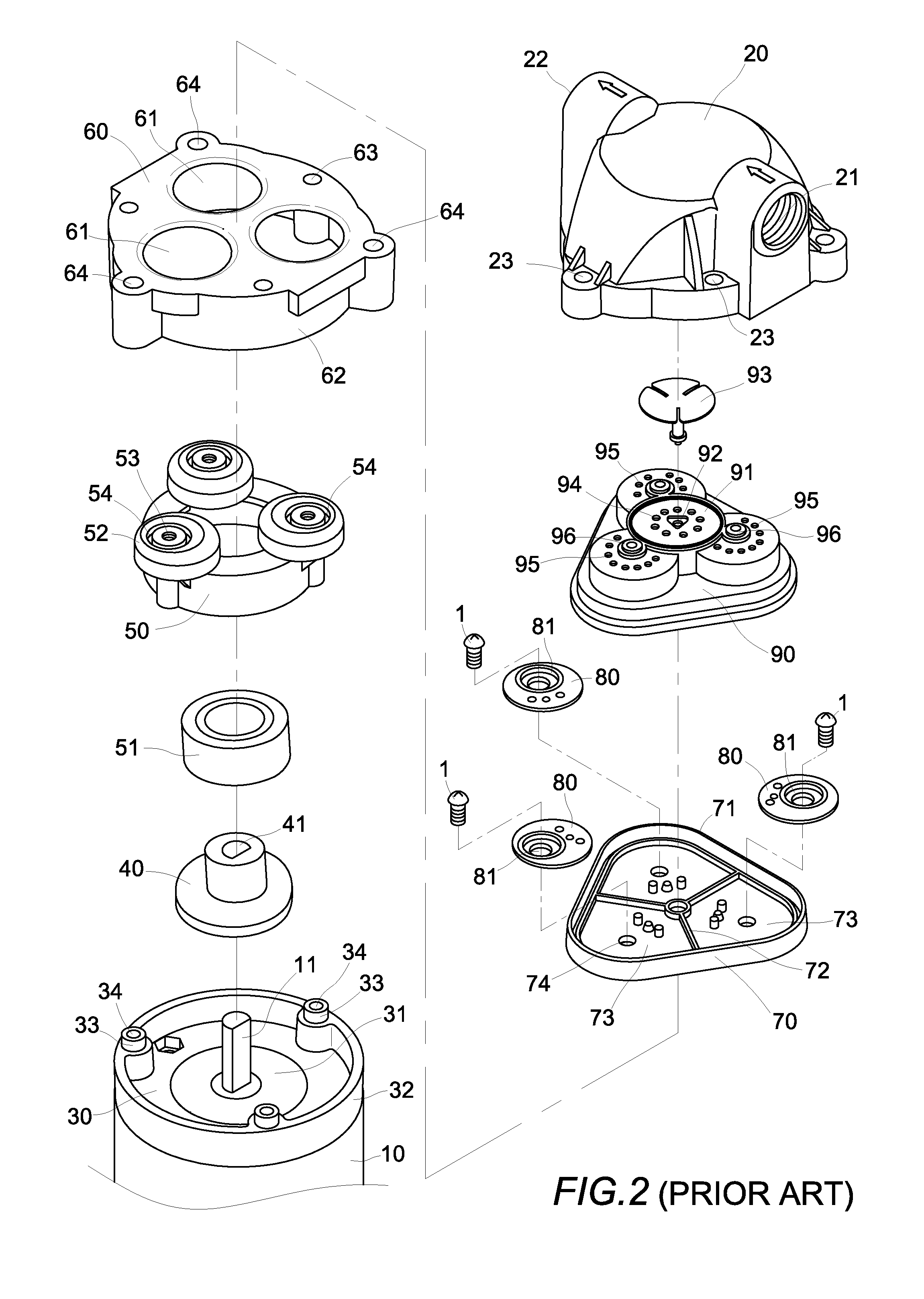

[0074]FIGS. 15 through 59 are illustrative figures for the vibration-reducing method for compressing diaphragm pump of the present invention. The compressing diaphragm pump comprises a motor 10 with an output shaft 11, a pump head cover 20, a motor upper chassis 30, a wobble plate 40 with integral protruding cam-lobed shaft, an eccentric roundel mount 50, a pump head body 60, a diaphragm membrane 70, three pumping pistons 80 and a piston valvular assembly 90, wherein, except as described below, components included in each part may be the same as those in the conventional compressing diaphragm pump as described above.

[0075]The basic operation mode of the compressing diaphragm pump is as follows: When the motor 10 is powered on, the wobble plate 40 is driven to rotate by the motor output shaft 11 so that three eccentric roundels 52 on the eccentric roundel mount 50 sequentially and constantly move in up-and-down reciprocal stroke. Meanwhile, three pumping pistons 80 and three piston a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com