Vibration-reducing structure for four-compression-chamber diaphragm pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

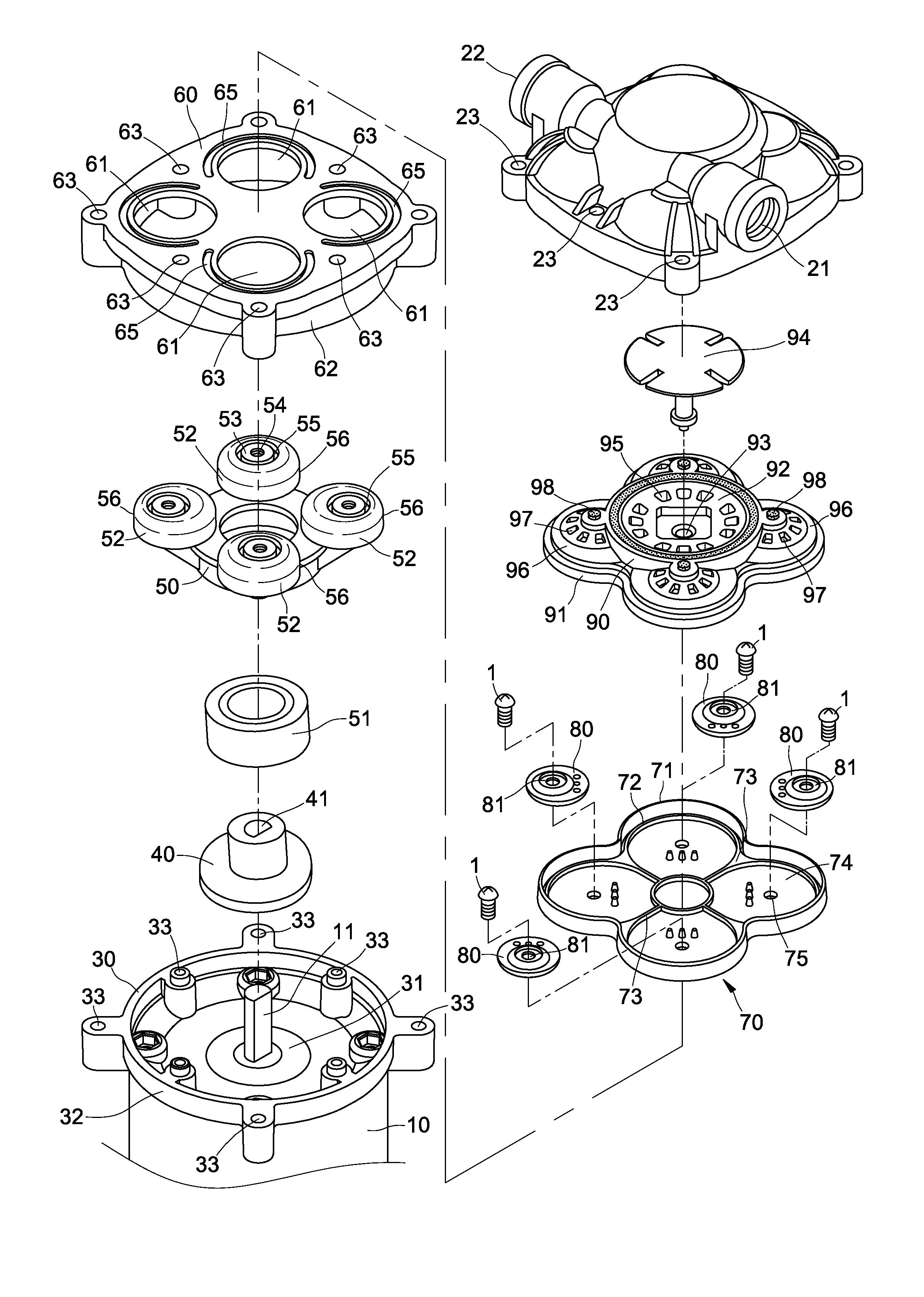

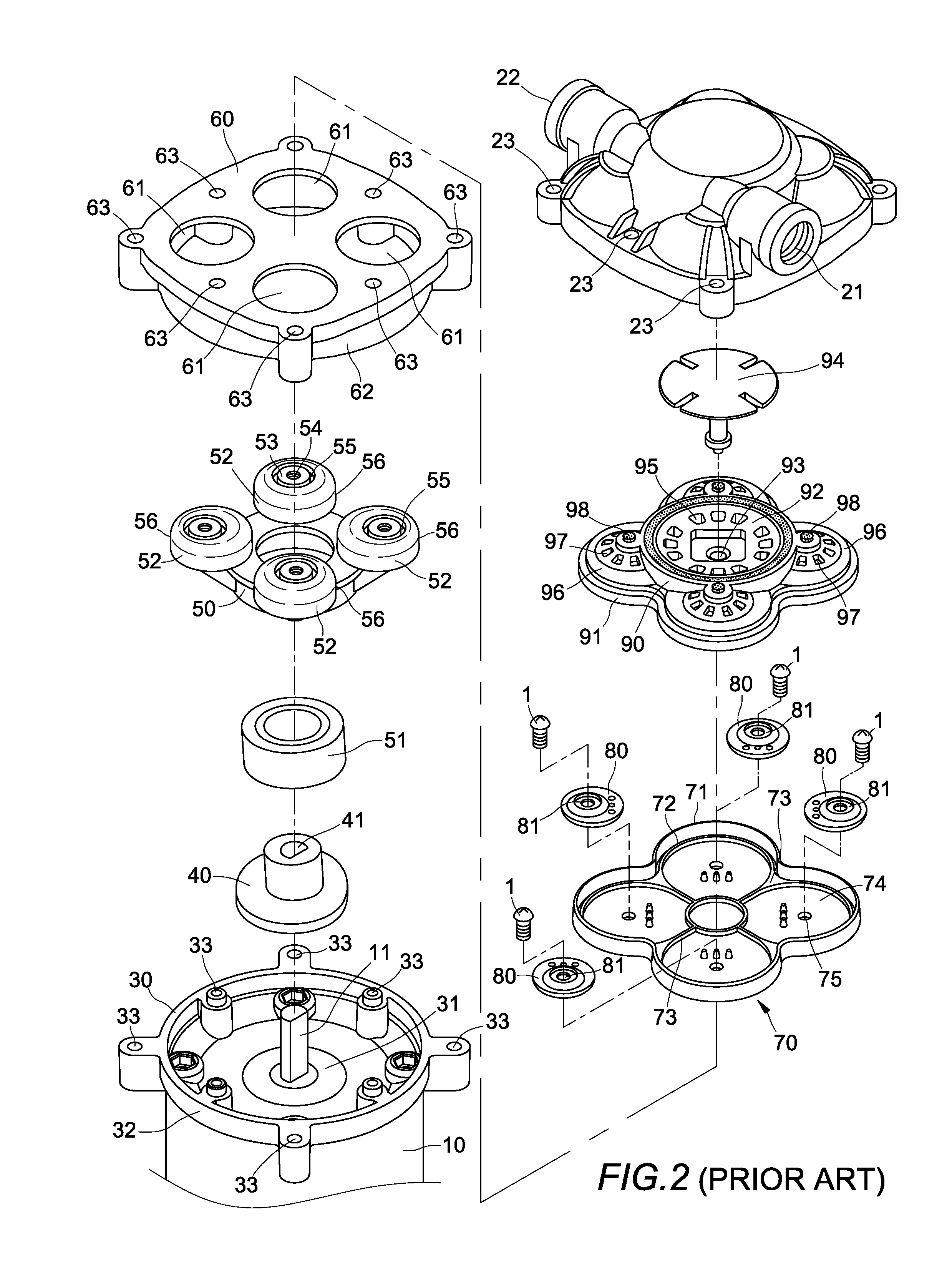

[0130]FIGS. 15 through 22 are illustrative figures of a first exemplary embodiment of a vibration-reducing structure for a four-compression-chamber diaphragm pump.

[0131]A basic curved groove 65 is circumferentially disposed around a portion of the upper side of each operating hole 61 in the pump head body 60 while a basic curved protrusion 77 is circumferentially disposed around a portion of each concentric annular positioning protrusion 76 at the bottom side of the diaphragm membrane 70 at positions corresponding to the positions of the mating basic curved grooves 65 in the pump head body 60 (as shown in FIGS. 20 and 21) so that each of the basic curved protrusions 77 at the bottom side of the diaphragm membrane 70 is completely inserted into each corresponding basic curved groove 65 in the upper side of the pump head body 60 upon assembly of the pump head body 60 and the diaphragm membrane 70, resulting in a shortened length of moment arm L2 from the basic curved protrusion 77 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com