Installation and method for individually tailored filling of blister packs with medication according to predetermined prescription data

a technology of predetermined prescription data and installation method, which is applied in the directions of drug and medication, packaging, special packaging, etc., can solve the problem of not bringing the operation of the installation to a standstill, and achieve the effect of simplifying the dispatch and marketing of the blister packs without a loss in the efficiency of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

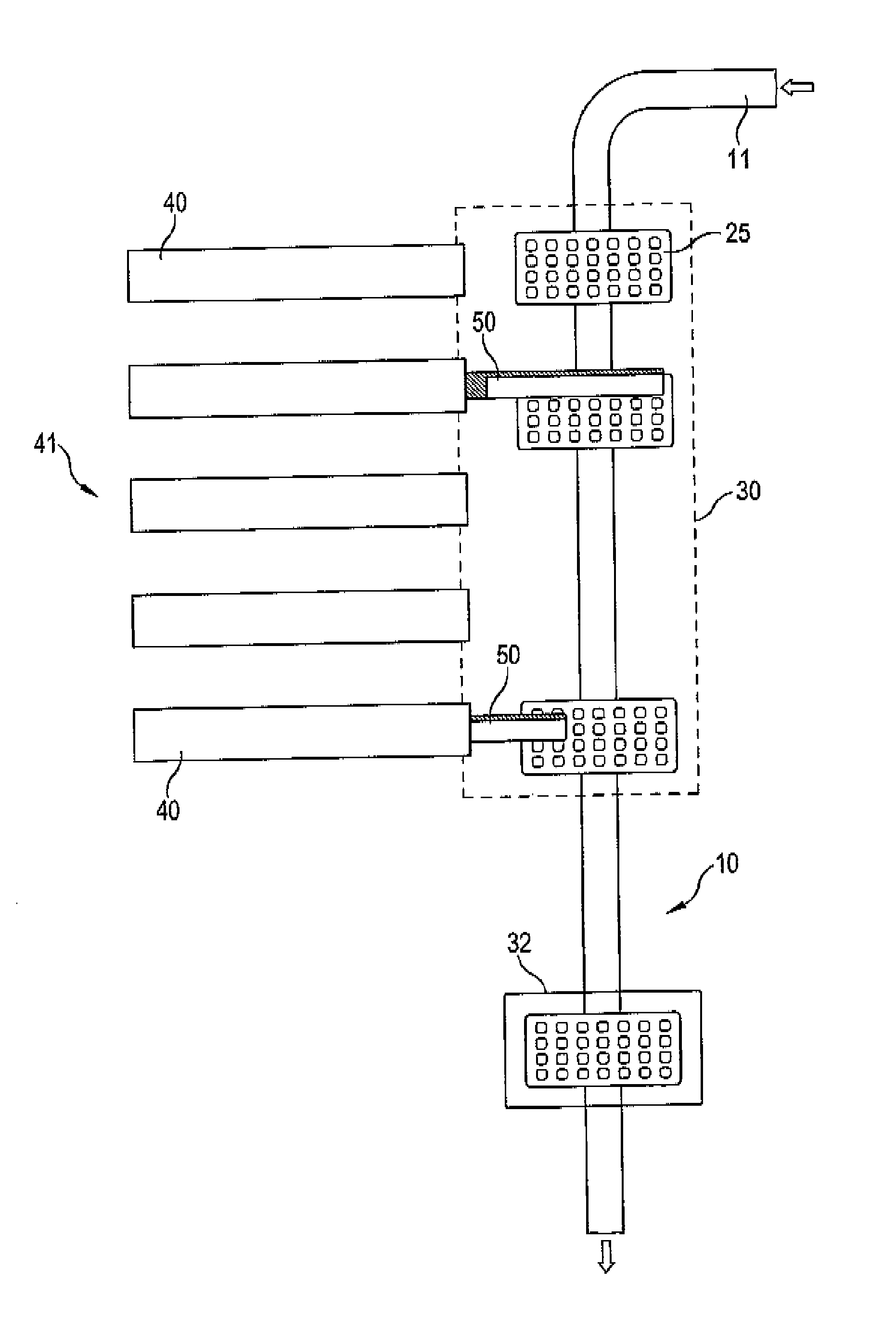

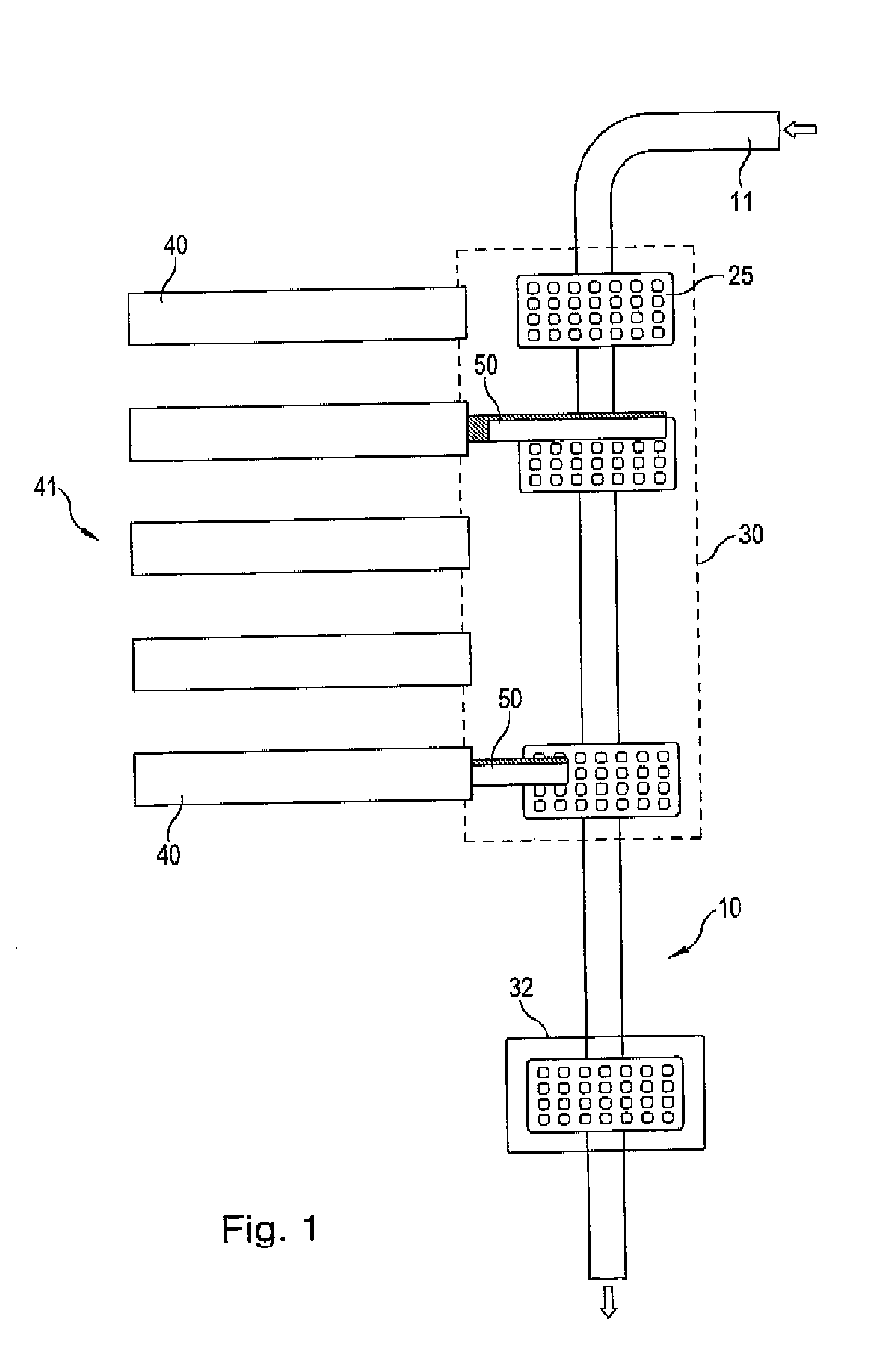

[0026]FIG. 1 is a schematic plan view of a filling module 41 of an embodiment of the installation according to the invention for individually tailored filling of blister packs 25. In the embodiment shown, such a filling module 41 comprises five medication filling stations 40 arranged one after the other, each of which is provided for output of dosing units of a particular medication type. The number of medication filling stations 40 combined in a filling module 41 is of course not limited to five, but can be selected according to space conditions or expediency. Likewise, the total number of medication filling modules 41 in the installation is not limited to a particular number. The total number of filling stations 40 in this context in principle determines the maximum number of medications which can be blister-packed with the installation, it also being possible for more than one filling station to be provided for medications which are used particularly frequently.

[0027]The installa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| mechanical force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com