Propellant feed circuit and a cooling method

a technology of propellant feed circuit and cooling method, which is applied in the field of aerospace, can solve the problems of difficult to remove the heat generated by such devices and few channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

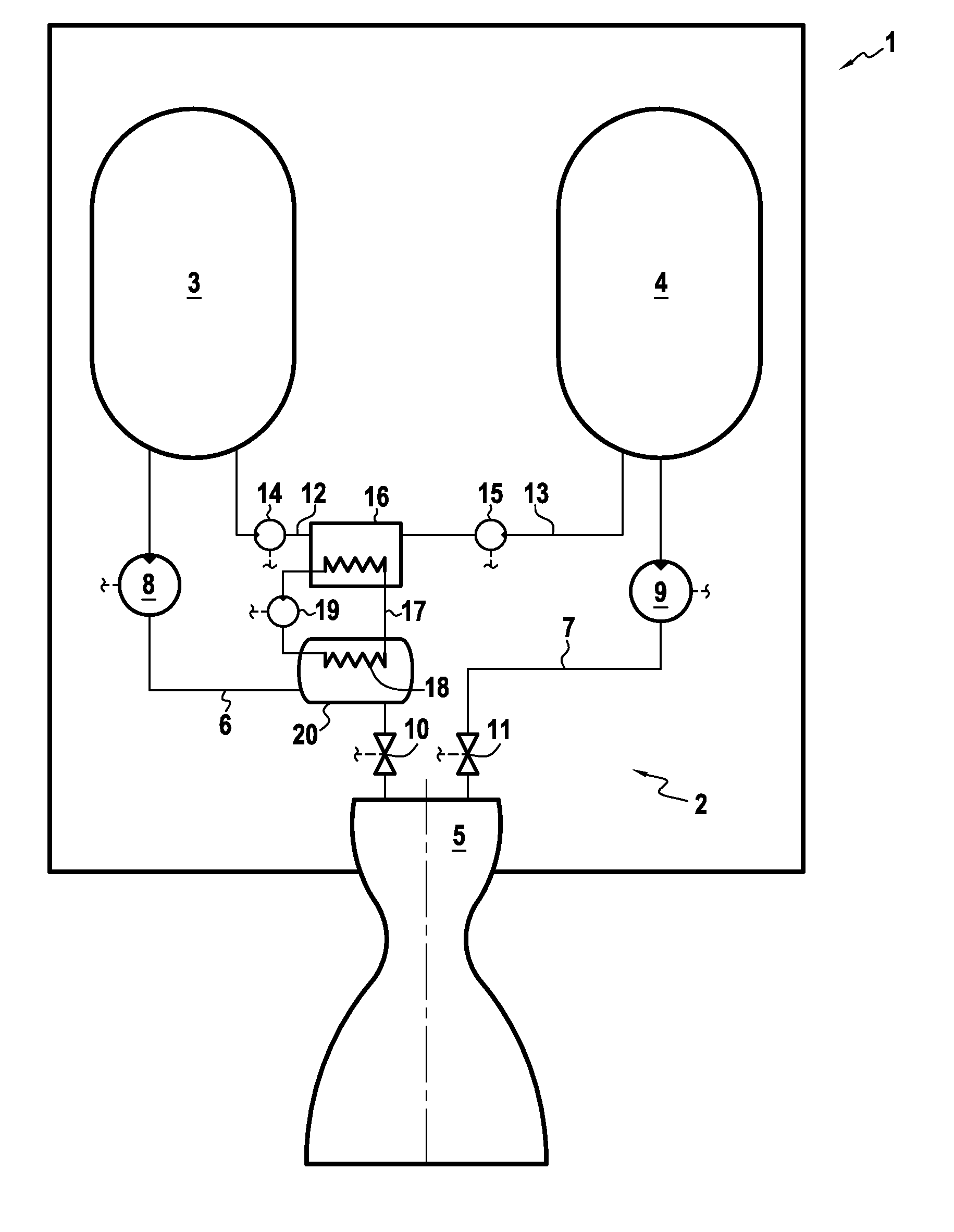

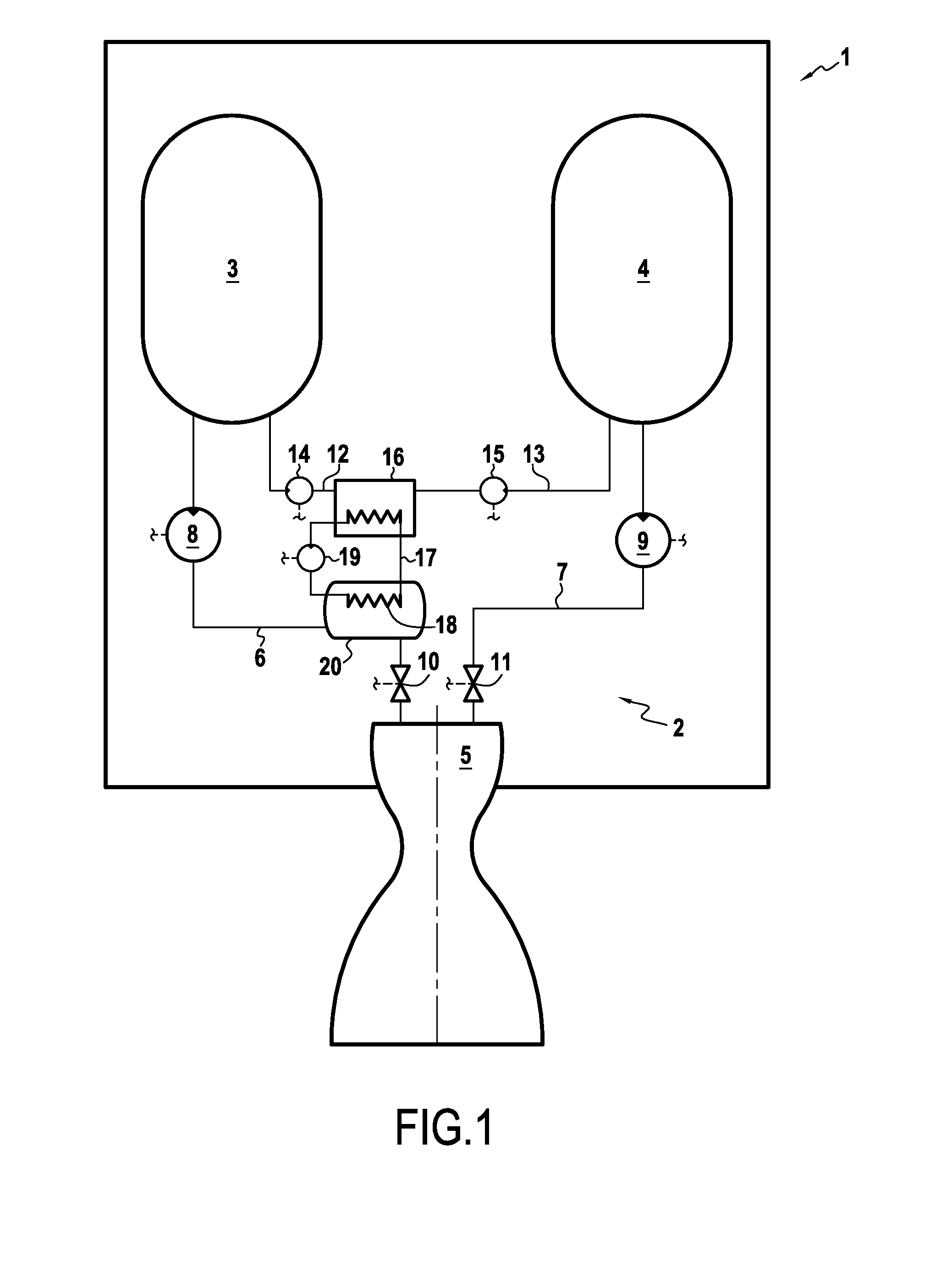

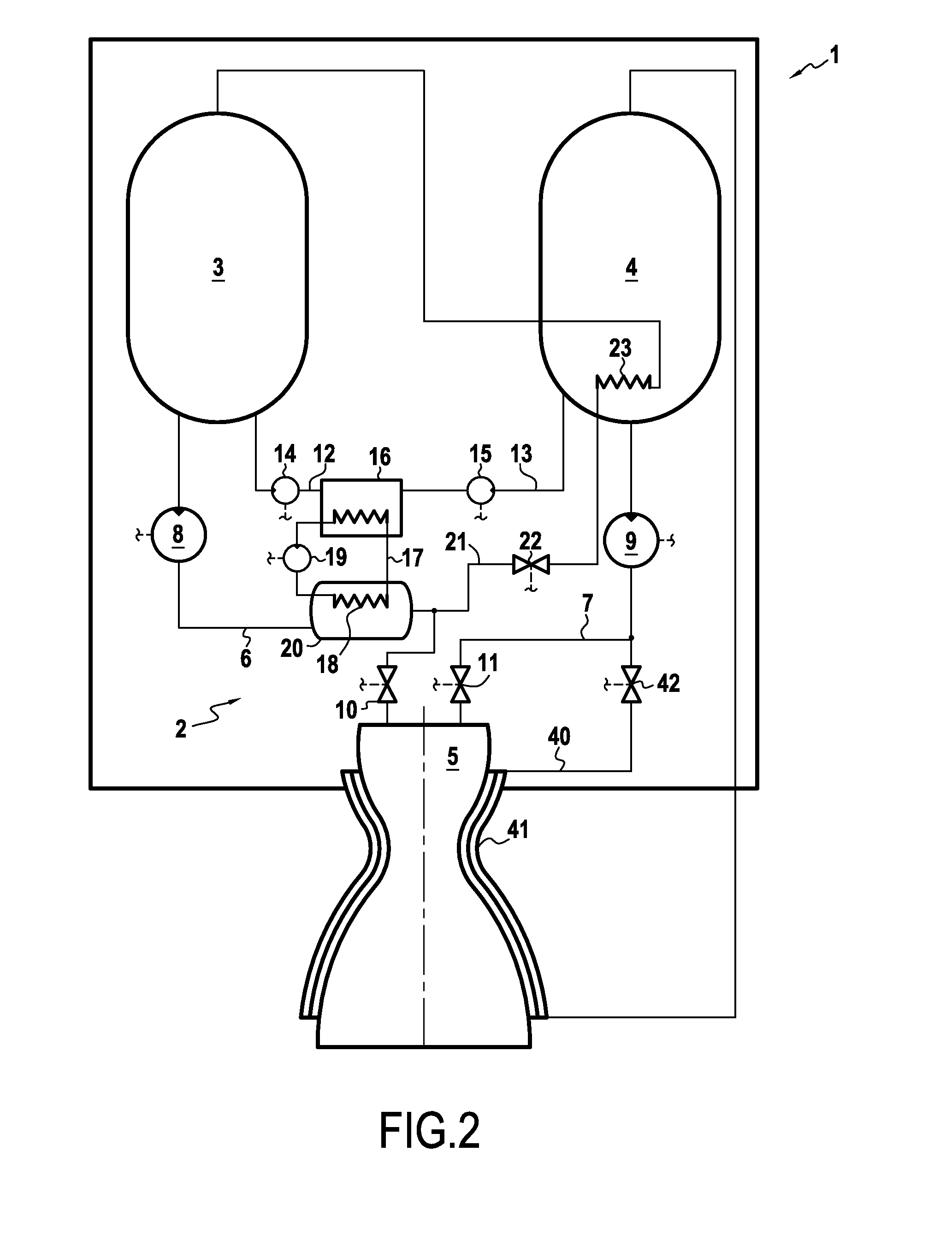

[0018]FIG. 1 is a diagram showing a vehicle 1, which may for example be a stage of a space launcher. For its propulsion, this vehicle 1 has a liquid propellant rocket-engine 2 with a first tank 3 for a first propellant, a second tank 4 for a second propellant, a thrust chamber 5 for combustion of a mixture of the two propellants and for accelerating the gas that results from combustion of the mixture, a first feed circuit 6 connected to the first tank 3 and to the first chamber 5 in order to bring the first propellant from the first tank 3 to the thrust chamber 5, and a second feed circuit 7 connected to the second tank 4 and to the thrust chamber 5 in order to bring the second propellant from the second tank 4 to the thrust chamber 5. The first and second propellants may be cryogenic propellants such as liquid hydrogen and liquid oxygen. Each of the feed circuits 6, 7 comprises a pump 8, 9 for causing the respective propellant to flow through each feed circuit 6, 7, and outlet valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com