Middle phase continuously variable valve timing system with intermediate lock pin and cam torque response control and method thereof

a technology of cam torque response control and lock pin, which is applied in the direction of analogue processes, machines/engines, instruments, etc., can solve the problems of response delay, delay in unlocking [lockingunlocking] of the lock pin, and decrease the efficiency of emission effect, so as to reduce the response delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

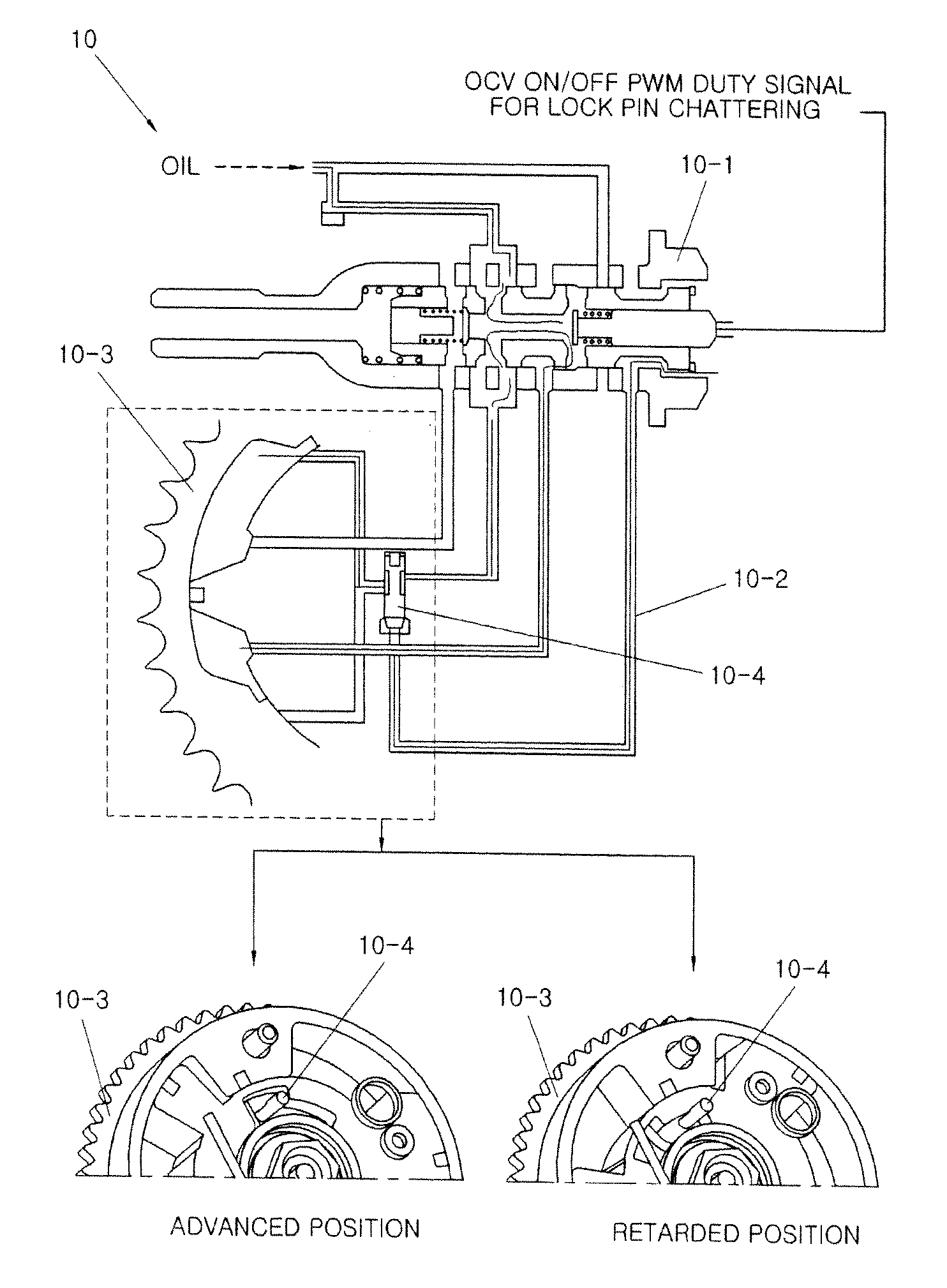

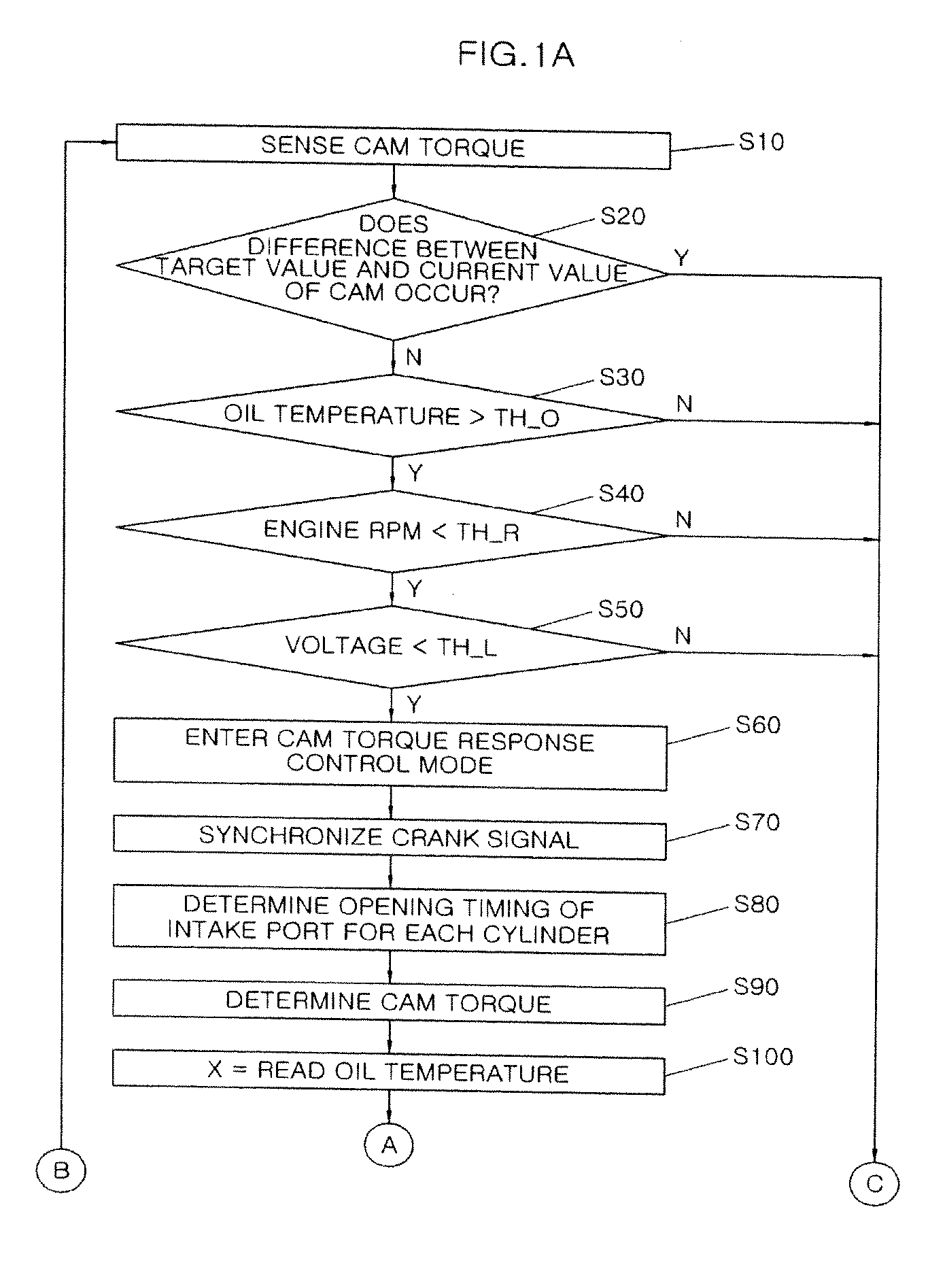

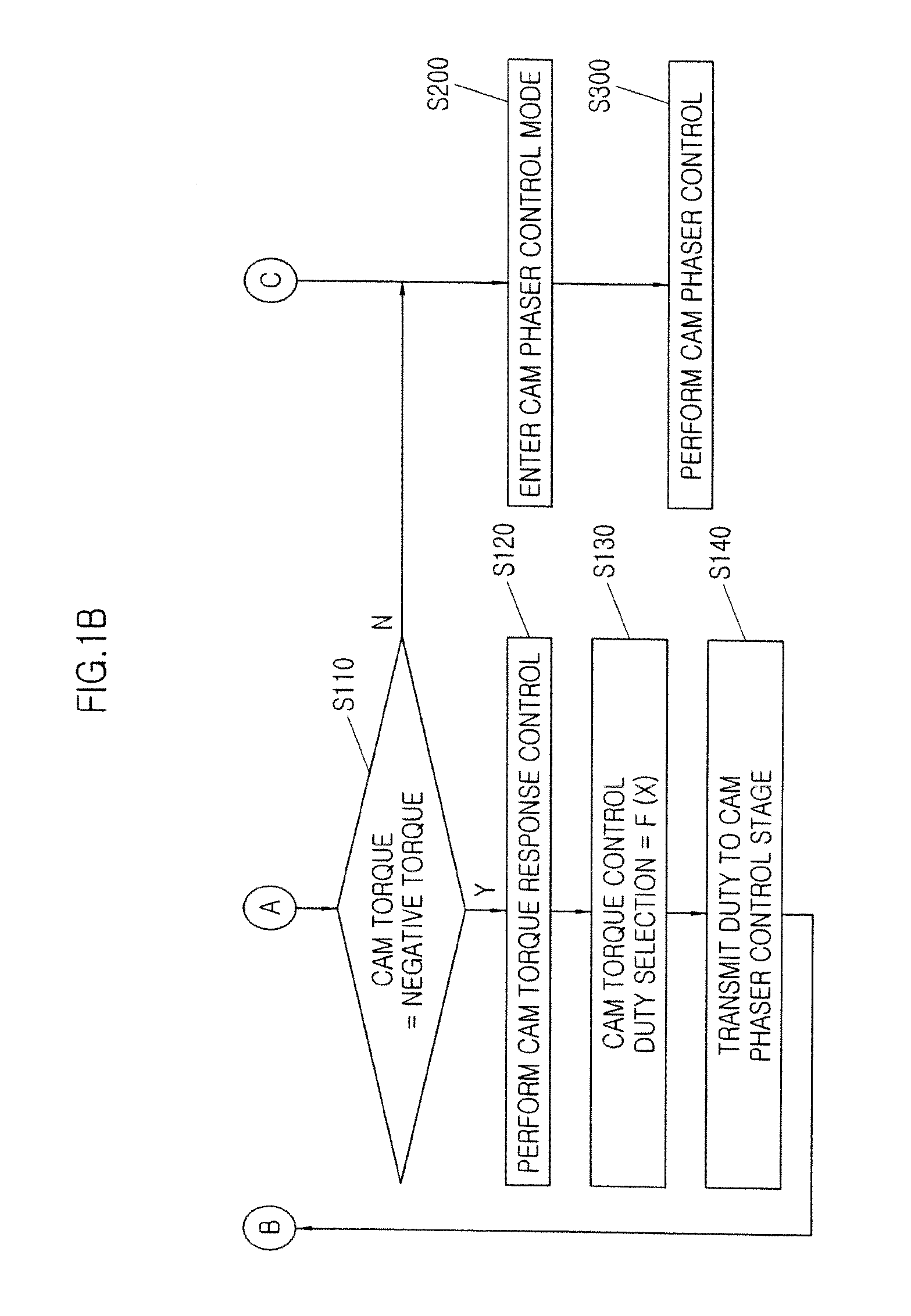

[0034]FIGS. 1A and 1B, 2, 3, and 4 illustrate an example of a middle phase continuously variable valve timing (CVVT) system with intermediate lock pin and cam torque response control and a method thereof.

[0035]Referring to FIGS. 1A and 1B, an intermediate lock pin and cam torque response control method for a middle phase continuously variable valve timing system includes sensing a cam torque when an engine starts (S10) and determining a difference between a target value and a current value of a cam (S20). A cam phaser control mode is entered when the difference between the target value and the current value of the cam occurs (S200 and S300), and a cam torque response control mode is entered (S30 to S140) when there is no difference between the target value and the current value of the cam. In this case, the occurrence of the difference between the target value and the current value of the cam represents a predetermined time period after an initial starting of the engine, and the non...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com