Hydraulic fracturing while drilling and/or tripping

a technology of hydraulic fracturing and subterranean formation, which is applied in the direction of wellbore/well accessories, survey, sealing/packing, etc., can solve the problems of time-consuming and expensive overall process of creating a productive wellbore, and achieve significant time and cost savings , the effect of reducing the requirements of the crew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 200

[0030]FIG. 5 depicts a flow chart of one disclosed method embodiment 200. A subterranean wellbore is drilled through a formation of interest at 202, for example, using conventional directional drilling, logging while drilling, and measurement while drilling techniques. During the drilling process in 202 logging while drilling (formation evaluation) data may optionally be acquired and evaluated at 204 in order to precisely locate and tag (identify) locations for subsequent hydraulic fracturing (stimulation). At 206 the surface system and the bottom hole assembly may be reconfigured in preparation for the hydraulic fracturing operation (e.g., by flushing the drilling fluid out of the system and connecting the drill string to the fracturing fluid blender). The drill string is pulled off bottom at 208 such that the fracture port (or ports) are located adjacent a region (or regions) to be fractured. After inflating (or expanding) the packers and thereby sealing the annulus about the frac...

embodiment 300

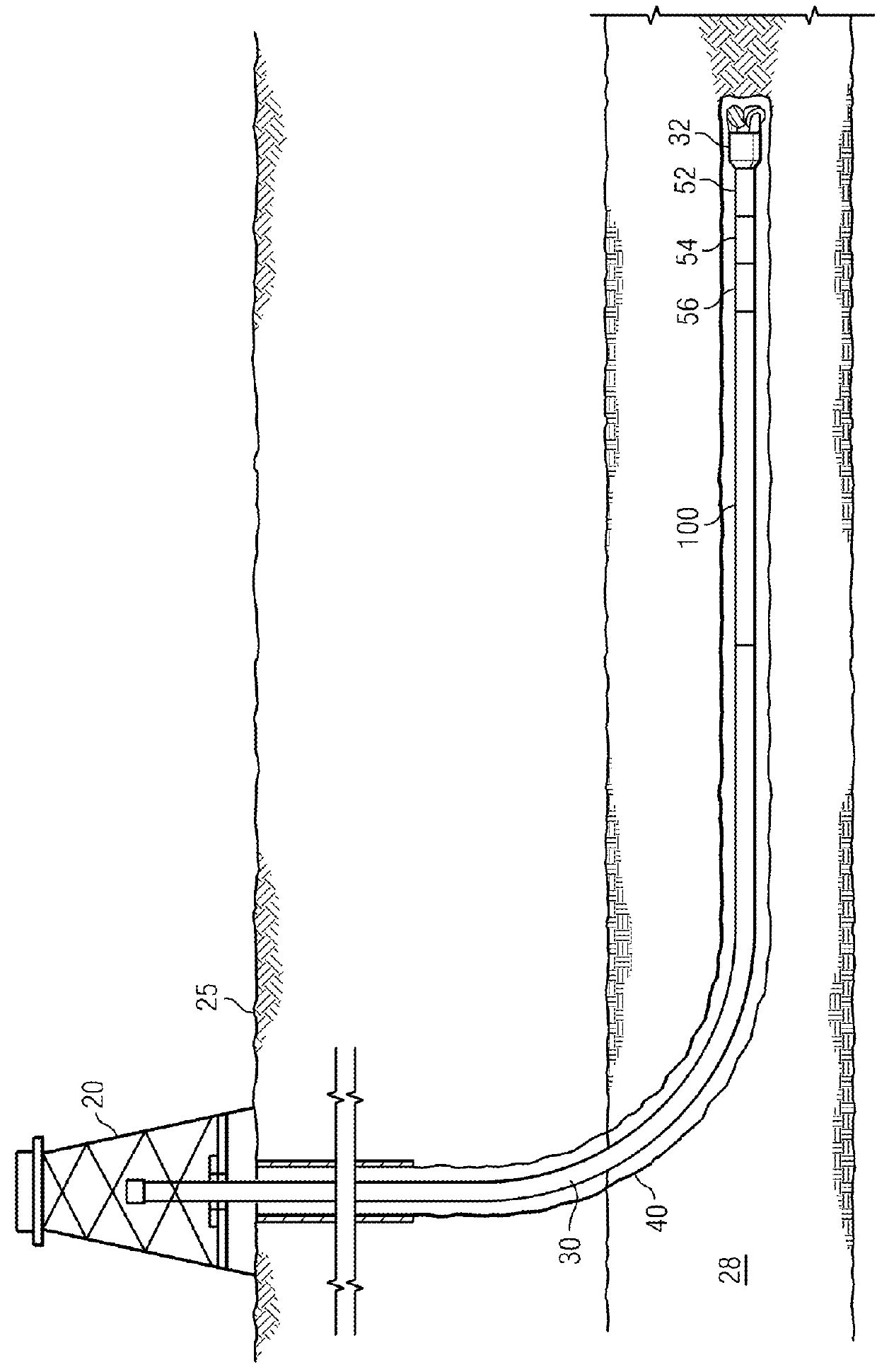

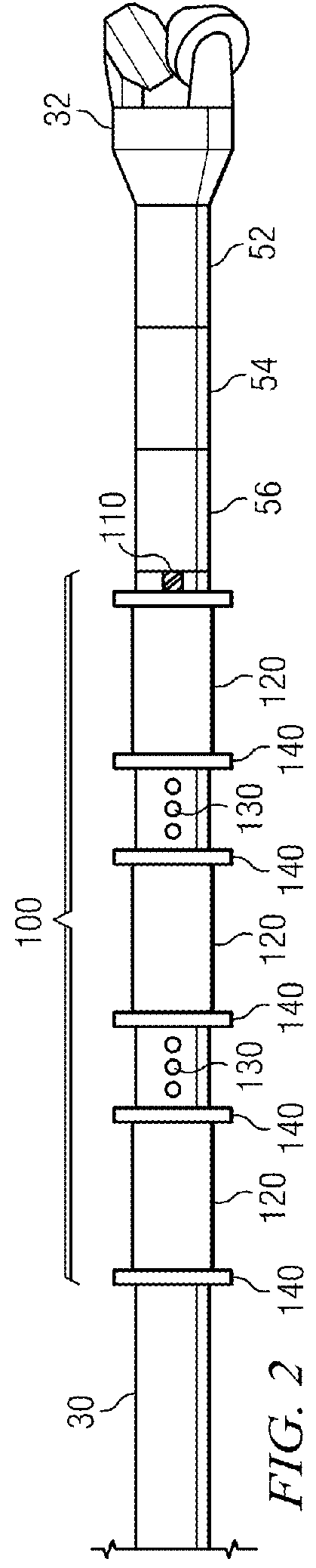

[0044]FIG. 1 depicts a flow chart of another disclosed method embodiment 300. A subterranean wellbore is drilled through a formation of interest at 202, for example, using conventional directional drilling, logging while drilling, and measurement while drilling techniques (as described above with respect to method 200 and FIG. 5). During the drilling process in 202 logging while drilling (formation evaluation) data may optionally be acquired and evaluated at 204 in order to precisely locate and / or tag (identify) locations for subsequent fracturing (stimulation). After the drilling operation has been finished, the drill string may be tripped out of the wellbore at 306 and the drill bit (and possibly other BHA components) replaced with a hydraulic fracturing assembly such as hydraulic fracturing assembly 100 or 100′ depicted on FIGS. 2 and 8. At 308 the surface system may be reconfigured in preparation for the fracturing operation, for example, as described above at 206 of FIG. 5. Suc...

embodiment 450

[0047]FIG. 13 depicts a flow chart of still another disclosed method embodiment 450, in this case, for fracturing while drilling and casing. Method 450 may employ, for example, one of the drill string configurations depicted on FIGS. 12A and 12B. A subterranean wellbore is drilled through a formation of interest at 452, for example, using a drill string including a casing while drilling assembly (e.g., as described above) and a hydraulic fracturing assembly (such as also described above). After the drilling operation has been completed, the surface system and the bottom hole assembly may be reconfigured at 454 (e.g., as described above at 206 of FIG. 5) in preparation of the fracturing operation. The drill string may be translated upward at 456 such that the frac ports in hydraulic fracturing assembly 430 are located adjacent a region of the formation that is to be fractured. After inflating the packers, high pressure fracturing fluid may then be pumped downhole at 458 to fracture t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com