Energy storage tank having function of fixing energy storage units

a technology of energy storage tank and function, which is applied in the field of energy storage structure, can solve the problems of low cold amount of ice balls, smaller density of ice balls than that of working liquids, etc., and achieve the effect of improving energy storage efficiency of energy storage tanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

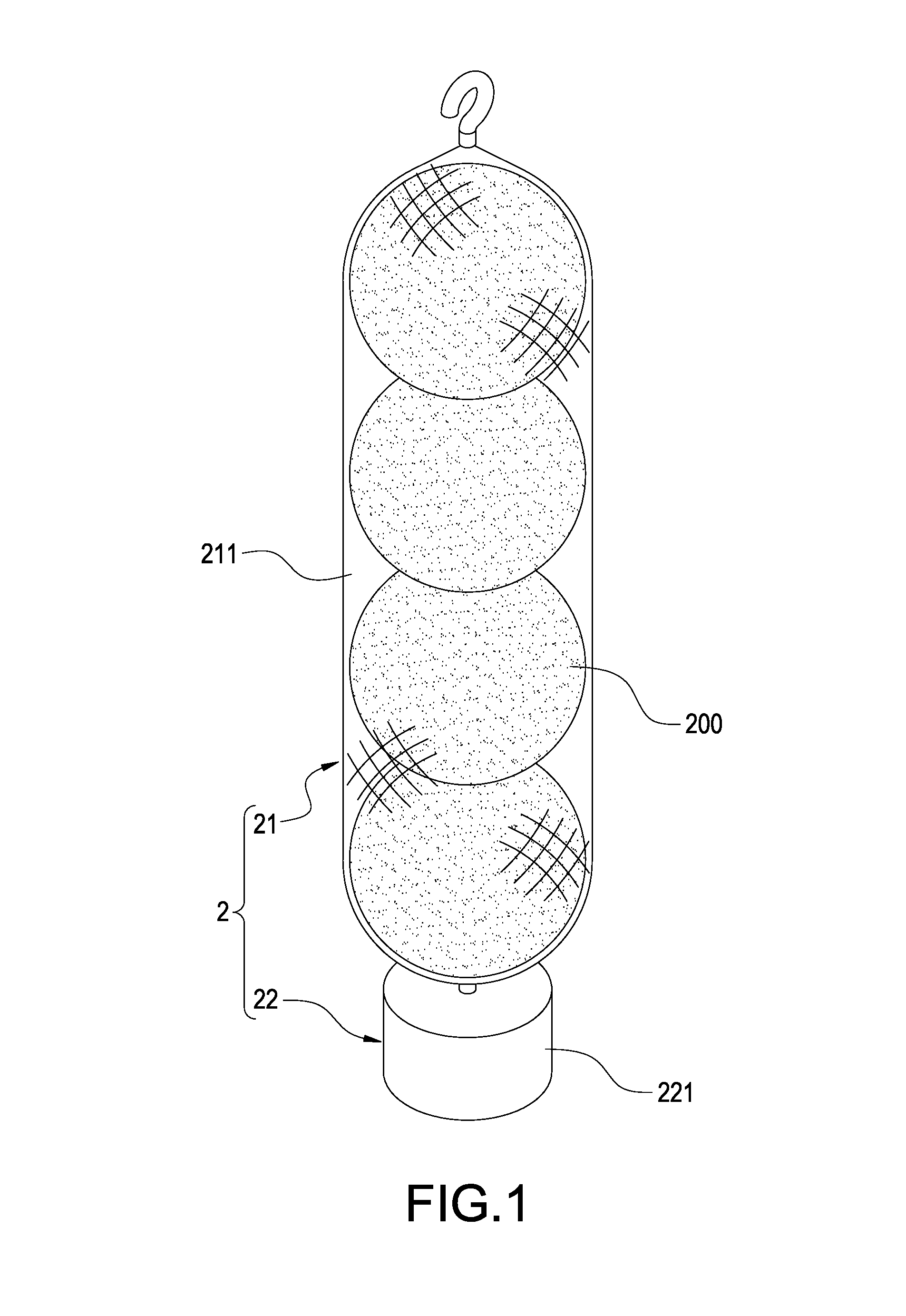

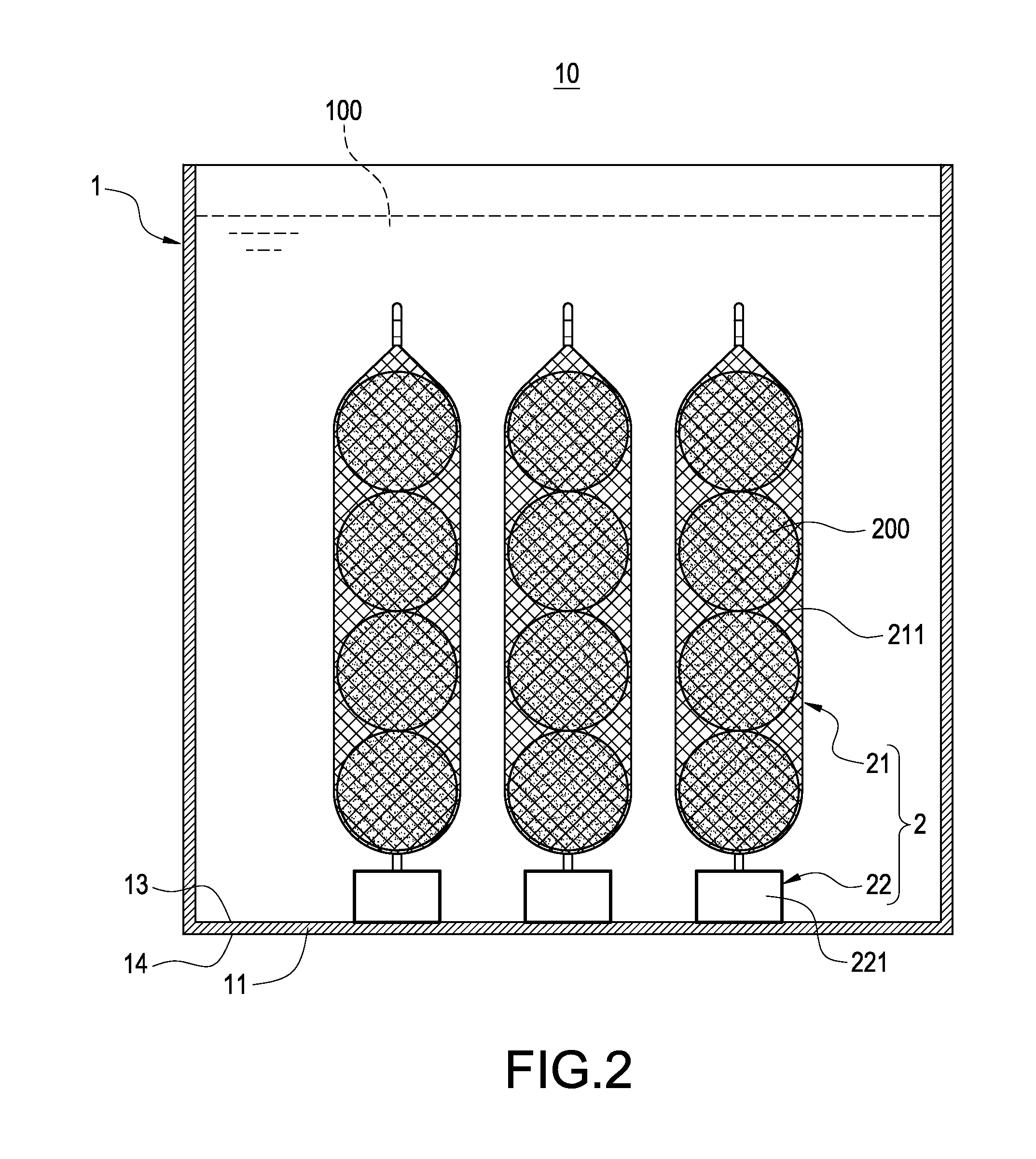

first embodiment

[0029]The detailed description is given below. The magnets 111 are install on the internal side surface 13 of the bottom plate 11. The installation part 22 is a magnetic part 222 made of a material containing iron. The magnet 111 and the magnetic part 222 attract to each other. In this way, through the magnetic attraction between the magnet 111 and the magnetic part 222, the magnetic part 222 is fixed to the bottom plate 11 such that the bag 211 and the energy storage units 200 are completely held under the surface of the working liquid 100, achieving the same function and effect as the

[0030]Please refer to FIG. 4, which shows the energy storage tank 10 according to the third embodiment of the present invention. The third embodiment is roughly similar to the second embodiment. The difference is that the magnets 111 are installed on the external side surface 14 in the third embodiment.

second embodiment

[0031]The detailed description is given below. The magnets 111 are installed either on the internal side surface 13 or on the external side surface 14; either of the above two cases will make the magnetic parts 222 be fixed steadily to the bottom plate 11 to achieve the same function and effect as the

[0032]Please refer to FIG. 5, which is the fourth embodiment of the present invention. The fourth embodiment is roughly similar to the first embodiment. The difference is that the bottom plate 11 is provided with plural magnetic parts 112 in the fourth embodiment.

[0033]A further explanation is given below. The bottom plate 11 is made of a material containing iron such that the bottom plate 11 itself is a magnetic part 112. The installation part 22 is a magnet 223. The magnet 223 and the magnetic part 112 attract to each other. In this way, through the magnetic attraction between the magnet 223 and the magnetic part 112, the magnet 223 is fixed to the bottom plate 11 such that the bag 21...

sixth embodiment

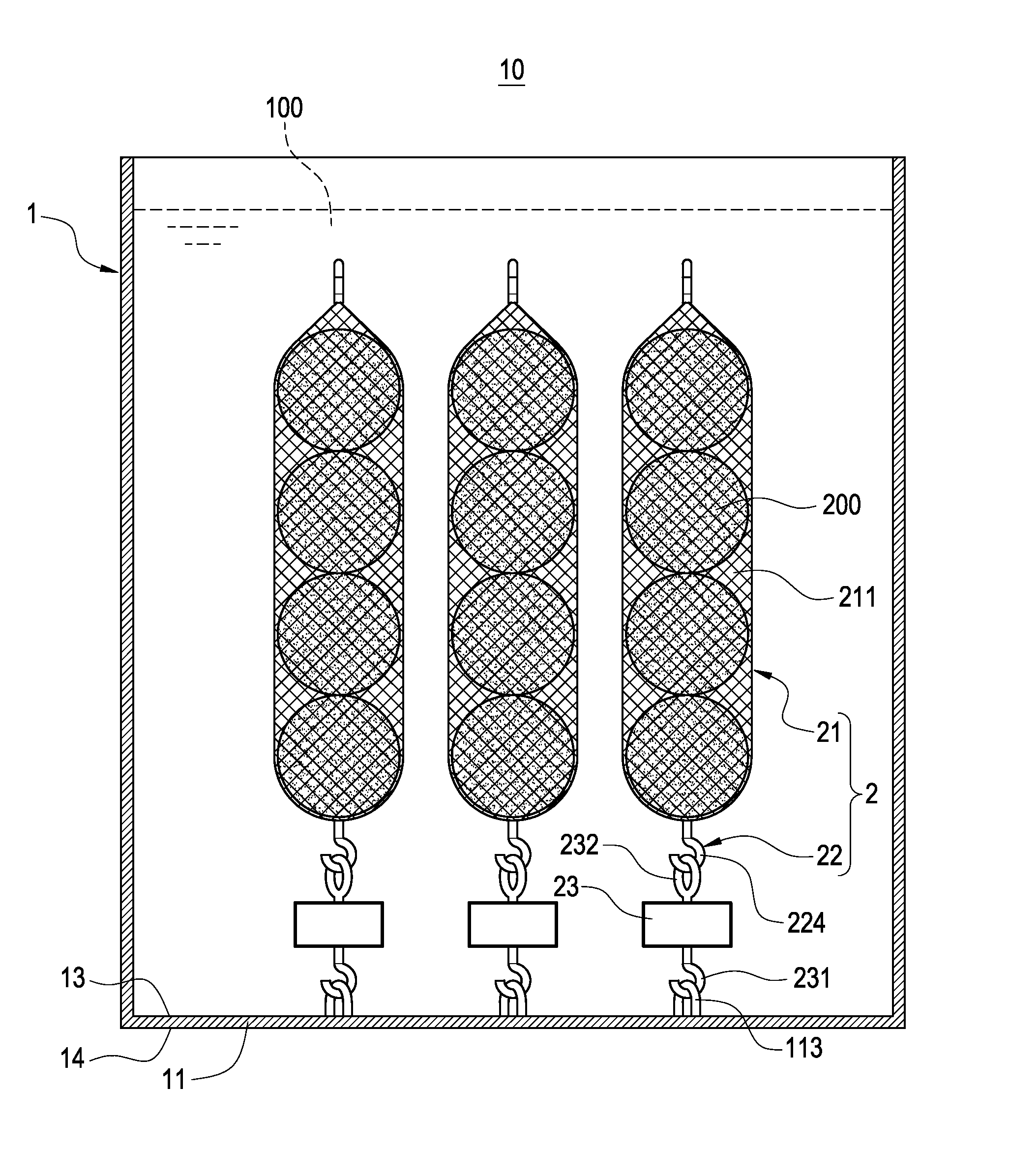

[0041]The detailed description is given below. As shown in FIG. 7, the first hook 113 has a roughly U-like shape and the second hook 224 has a roughly C-like shape. The U-like hook and the C-like hook hook to each other. As shown in FIG. 8, the first hook 113 has a roughly C-like shape and the second hook 224 has a roughly O-like shape. The C-like hook and the O-like hook can also hook to each other, achieving the same function and effect as the However, the fixing assembly 2 is apt to sway in the working liquid 100. The hook which has a U-like or O-like shape can prevent the two attached hooks from swaying and separating from each other to enhance the hooking stability.

[0042]Similarly, both of the first hook 113 and the second hook 224 can have a C-like shape. These two C-like hooks can hook to each other to achieve the same function and effect as the sixth embodiment.

[0043]Please refer to FIG. 9, which is the eighth embodiment of the present invention. The eighth embodiment is ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com