Riser stabilisation

a technology of stabilizing and rising towers, applied in waterborne vessels, drilling accessories, borehole/well accessories, etc., can solve problems such as significant fatigue, and achieve the effect of maximizing the corrective effect of thrust units and maximizing the cancelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

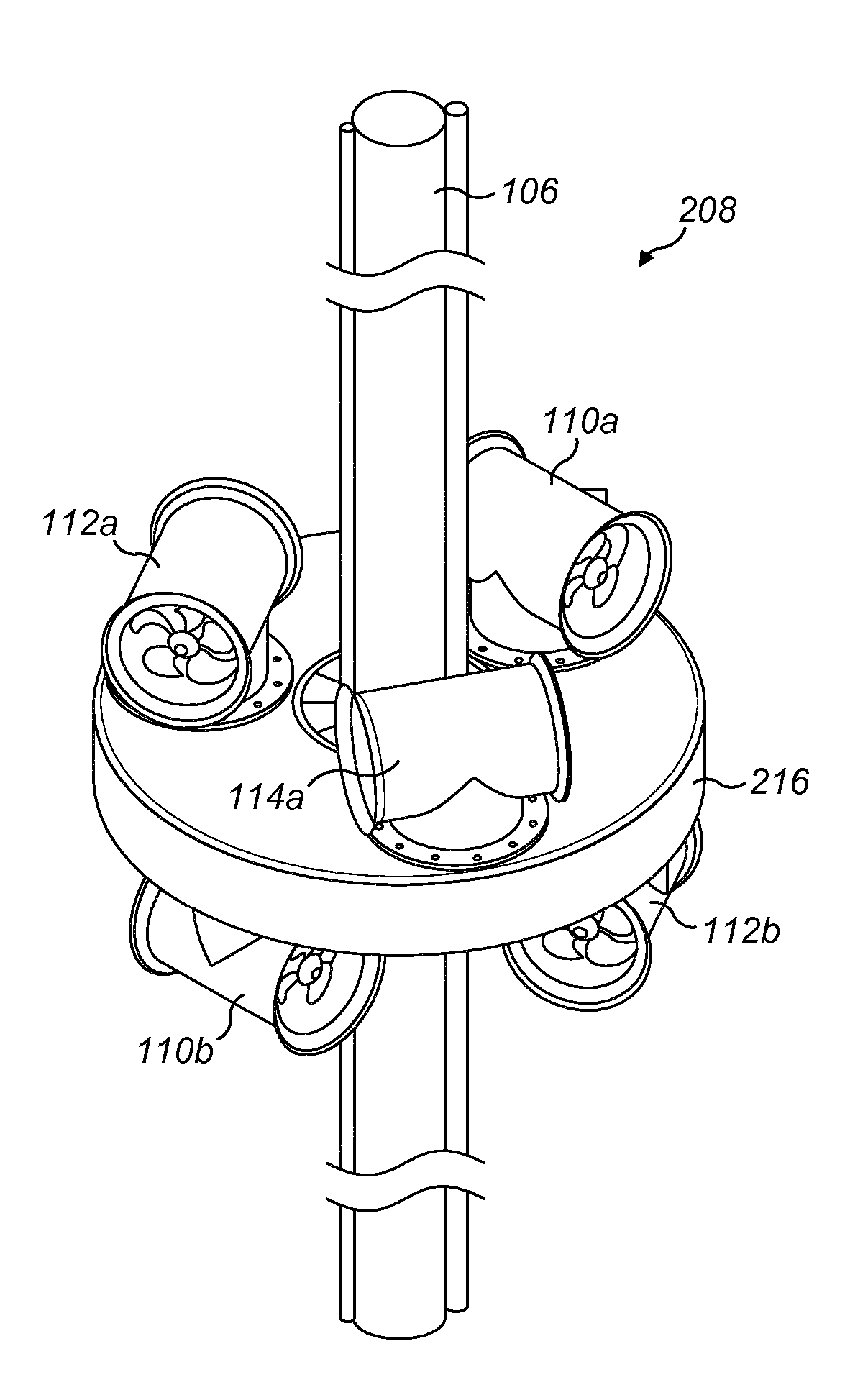

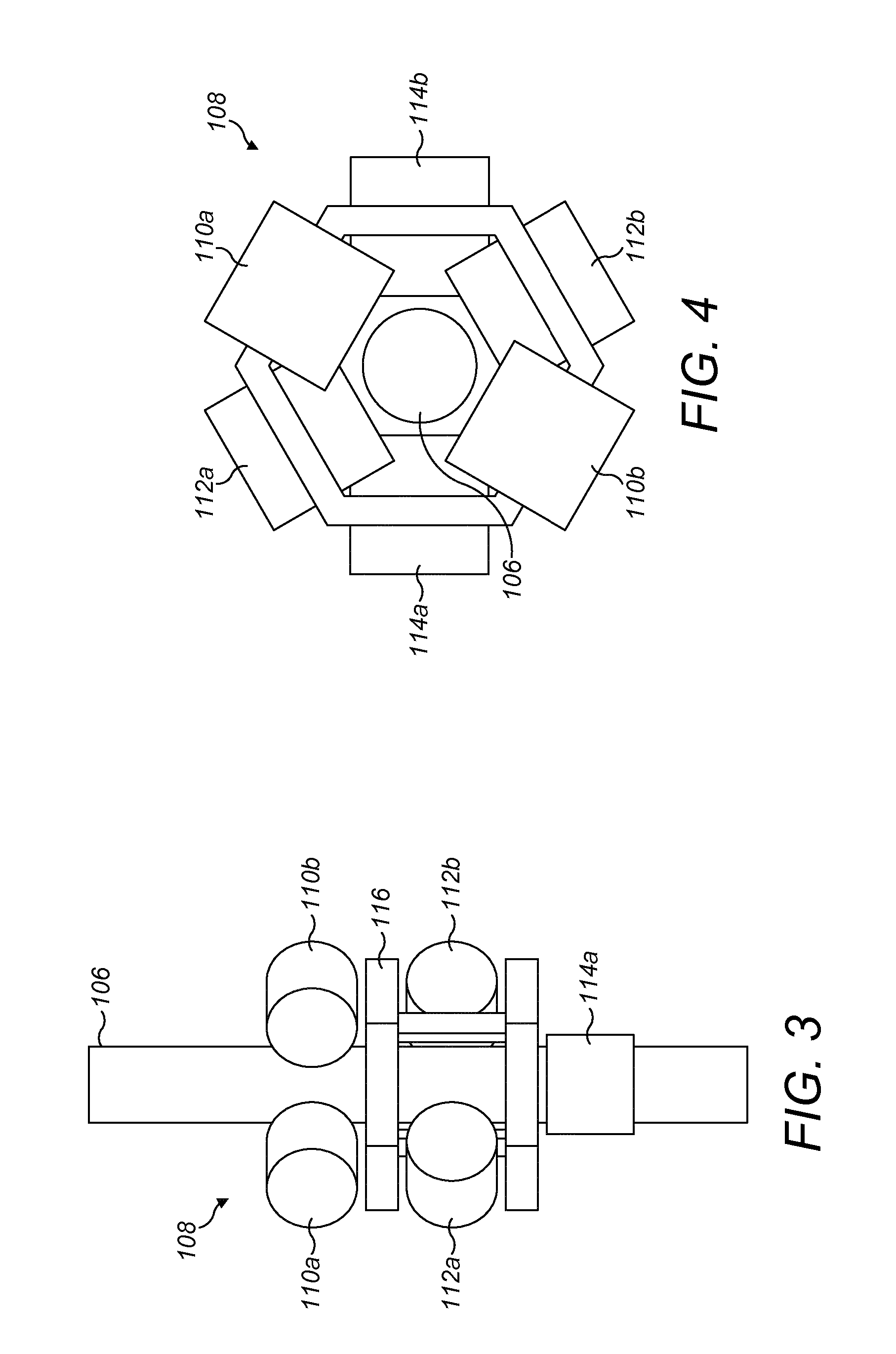

Image

Examples

Embodiment Construction

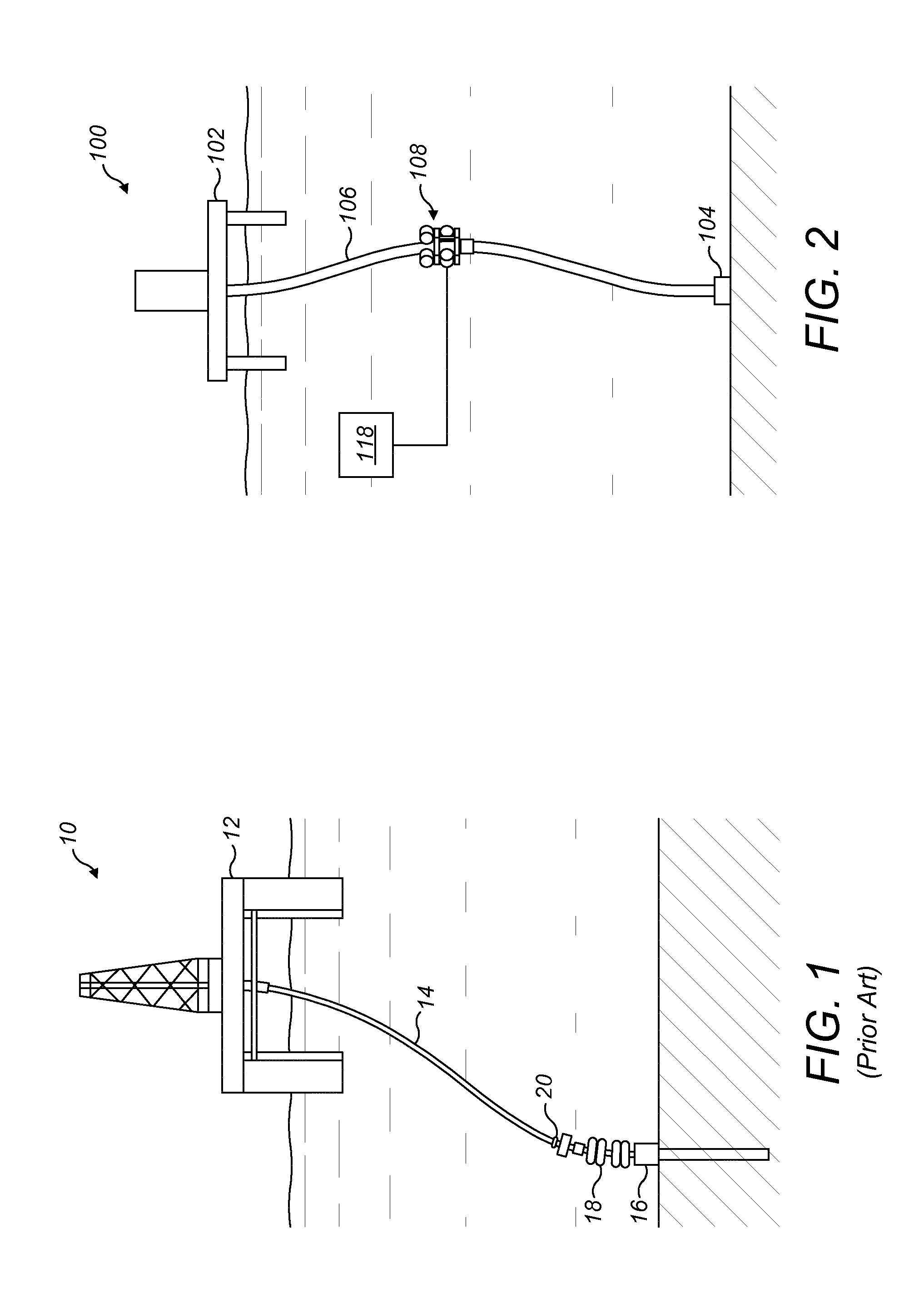

[0062]FIG. 1 shows a simplified diagram of a conventional offshore installation 10. The installation 10 comprises a floating platform 12 (formally a floating production, storage, and offloading system), a production riser 14, and a wellhead 16. The production riser 14 connects the floating platform 12 to the wellhead 16 via a lower riser package 18 (also known as a Christmas tree) and a blow-out protector (BOP) 20. The riser 14 is typically tensioned by a heave compensating system, which is a system that tries to compensate for the relative movement of the floating platform 12 with respect to the seabed, in order to improve the stability of the riser 14.

[0063]Fatigue problems at the upper part of the riser 14 occur at all water depths due to motion of the floating platform 12. It is predominantly roll and pitch motions (i.e. rotation about the horizontal axes) that cause bending moments in the riser 14, but surge and sway motions can also contribute. Tension variations in a heave co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com