Drum electrode, method for producing drum electrode, plating device, method for producing resin molded body, and method for producing metal porous body

a drum electrode and drum electrode technology, applied in the direction of electrolysis components, electrolysis processes, contact devices, etc., can solve the problems of reducing current efficiency, and achieve the effect of convenient maintenance during operation and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0096]1>

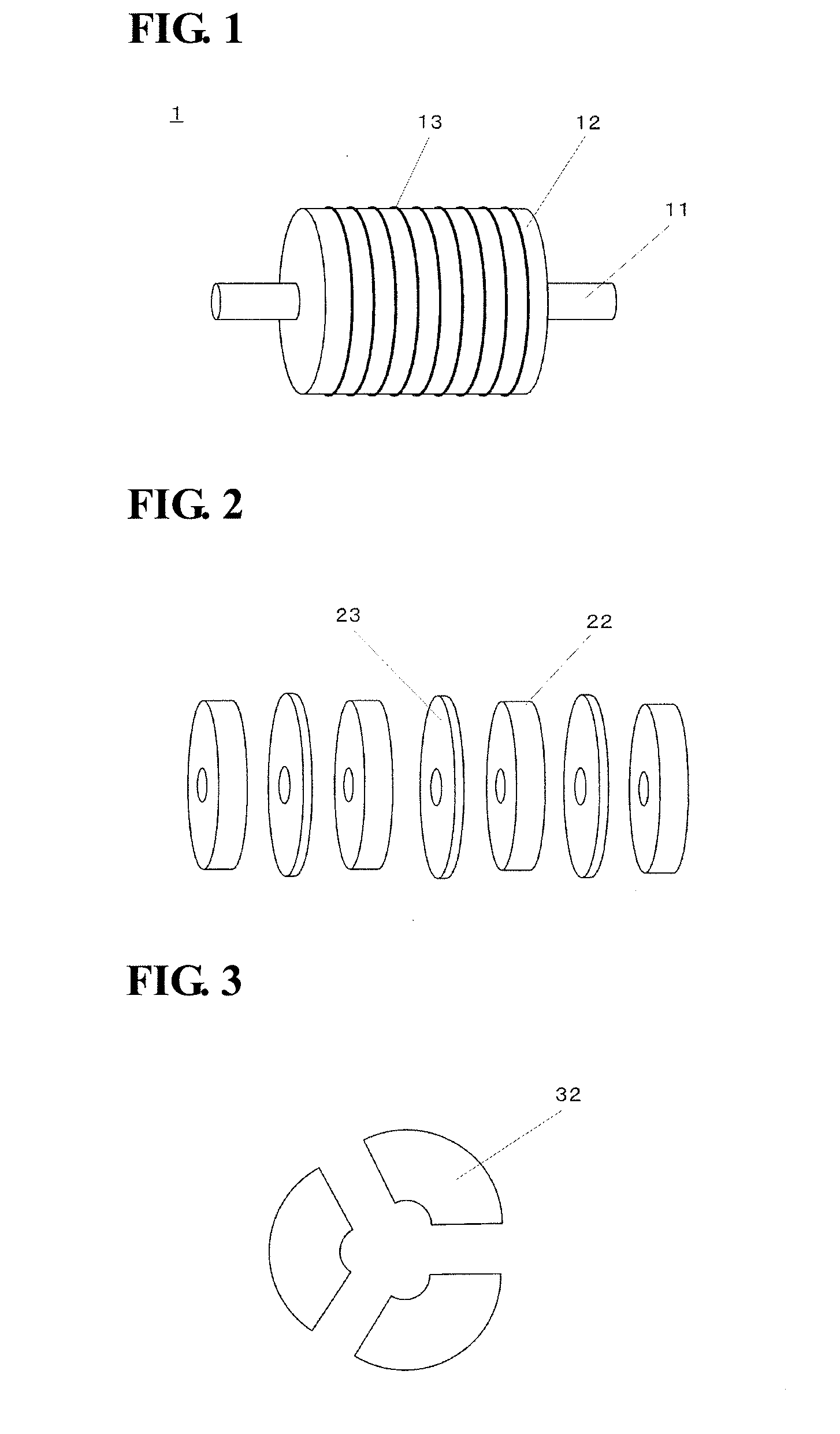

[0097]24 Disks made of aluminum with a thickness of 1 mm and a diameter of 200 mm were prepared, and a through-hole with a diameter of 40 mm was formed in the center of each of the disks.

[0098]25 Insulating disks made of vinyl chloride with a thickness of 4 mm and a diameter of 199 mm were prepared, and a through-hole with a diameter of 40 mm was formed in the center of each of the disks.

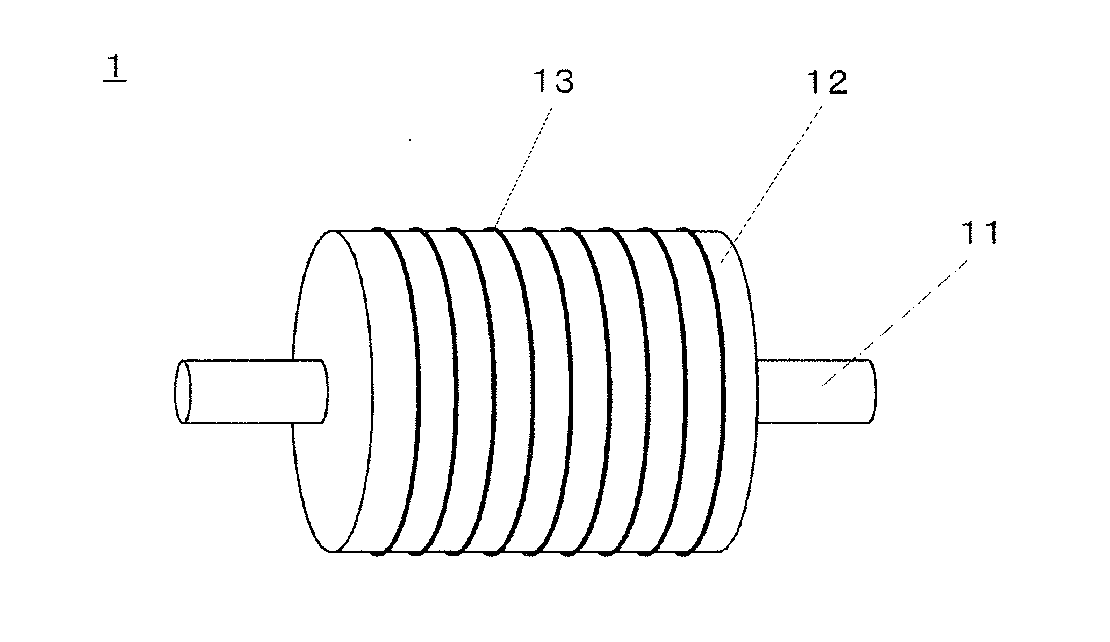

[0099]The disks made of aluminum and the insulating disks were alternately arranged and fixed firmly with bolts. A power feeding layer made of titanium with a diameter of 39 mm and a length of 250 mm was inserted into the through-hole portion in the center, and fixed firmly with a jig. Thus, a drum electrode 1 was obtained, in which linear projecting electrodes continuously extending in the circumferential direction with a width of 1 mm were formed at an interval of 4 mm.

[0100]The projecting electrodes of the drum electrode 1 thus obtained were subjected to aluminum plating treatment in orde...

example 2

[0110]2>

[0111]A drum made of aluminum with a diameter of 200 mm was prepared, and 24 linear projections extending continuously in the circumferential direction were formed at an interval of 4 mm. The width of the projections was set at 1 mm, and the height of the projections was set at 1.5 mm.

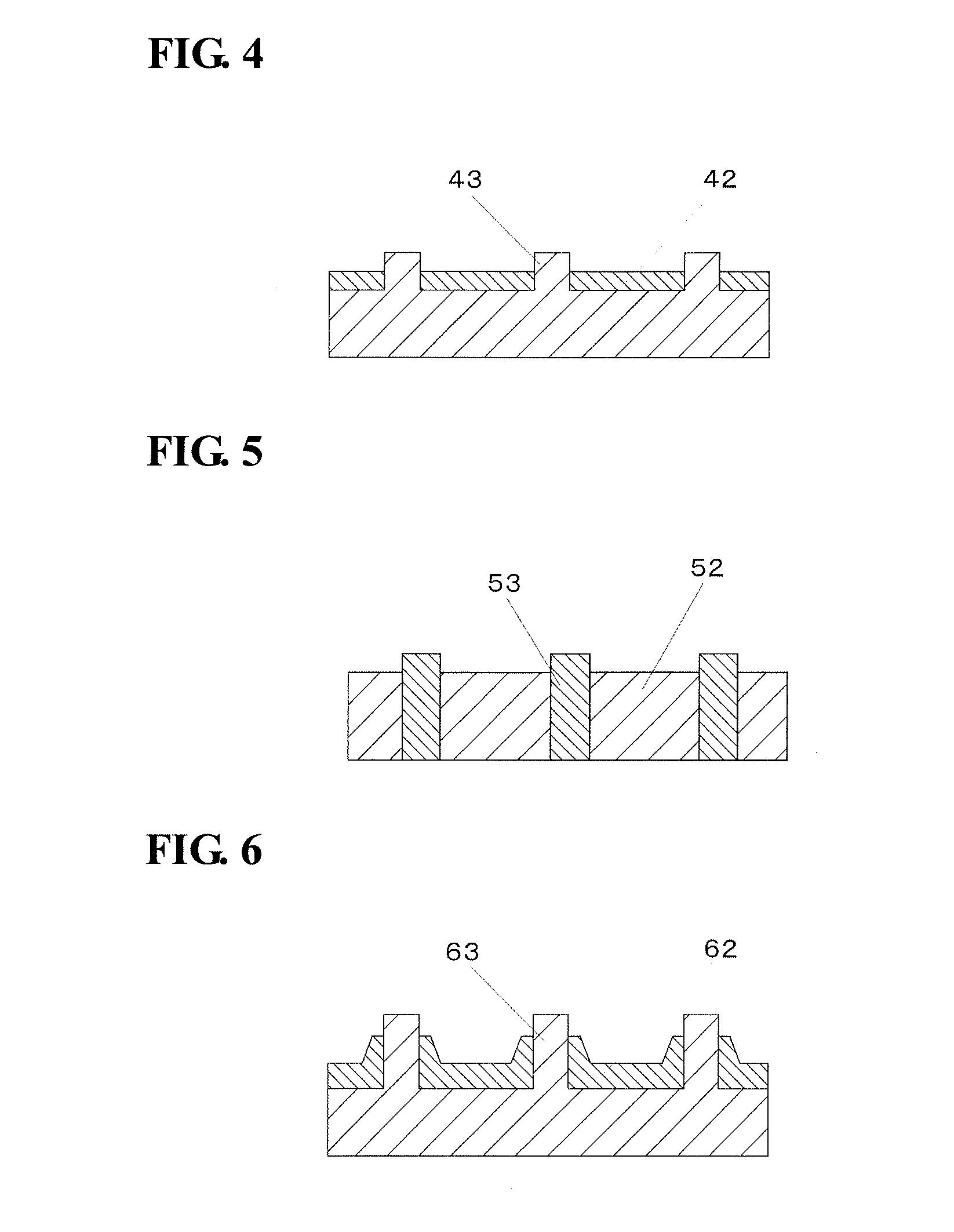

[0112]The entire surface of the aluminum drum was coated with a fluororesin (ETFE) with a thickness of 0.6 mm. Since the fluororesin layer was also formed on the surfaces of the projections, the surface coated with the fluororesin was scraped until the surfaces of the projections were exposed. Aluminum plating was grown with a thickness of 0.5 mm on the surfaces of the projections (aluminum) exposed from the surface of the fluororesin. Thus, a drum electrode 2 was obtained, in which linear projecting electrodes 63 continuously extending in the circumferential direction with a width of 1 mm were formed at an interval of 4 mm. FIG. 6 is an enlarged cross-sectional view of a surface portion of the...

example 3

[0115]3>

[0116]A drum made of aluminum with a diameter of 200 mm was prepared, and by subjecting the surface thereof to anodic oxide coating treatment, an anodic oxide film of aluminum was formed. The thickness of the anodic oxide film of aluminum was about 10 μm.

[0117]On the surface of the drum on which the anodic oxide film had been formed, 24 grooves continuously extending in the circumferential direction were formed at an interval of 4 mm. The width of the grooves was set at 1 mm, and the depth of the grooves was set at 0.5 mm. By subjecting the surface of the drum to aluminum plating treatment, aluminum plating was grown in the grooves. Aluminum plating was formed so as to project from the surface of the anodic oxide film by 0.5 mm. Thus, a drum electrode 3 was obtained, in which linear projecting electrodes 73 continuously extending in the circumferential direction with a width of 1 mm were formed at an interval of 4 mm. FIG. 7 is an enlarged cross-sectional view of a surface p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical conductivity | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com