Expandable LNG processing plant

a technology of liquefied natural gas and processing plant, which is applied in the direction of cold treatment separation, gas handling/storage effect, solidification, etc., can solve the problems of increasing the cost of traditional onshore lng storage and offloading facilities, affecting the overall installation cost of lng projects, and affecting the capacity of the plant. , to achieve the effect of expanding the plant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

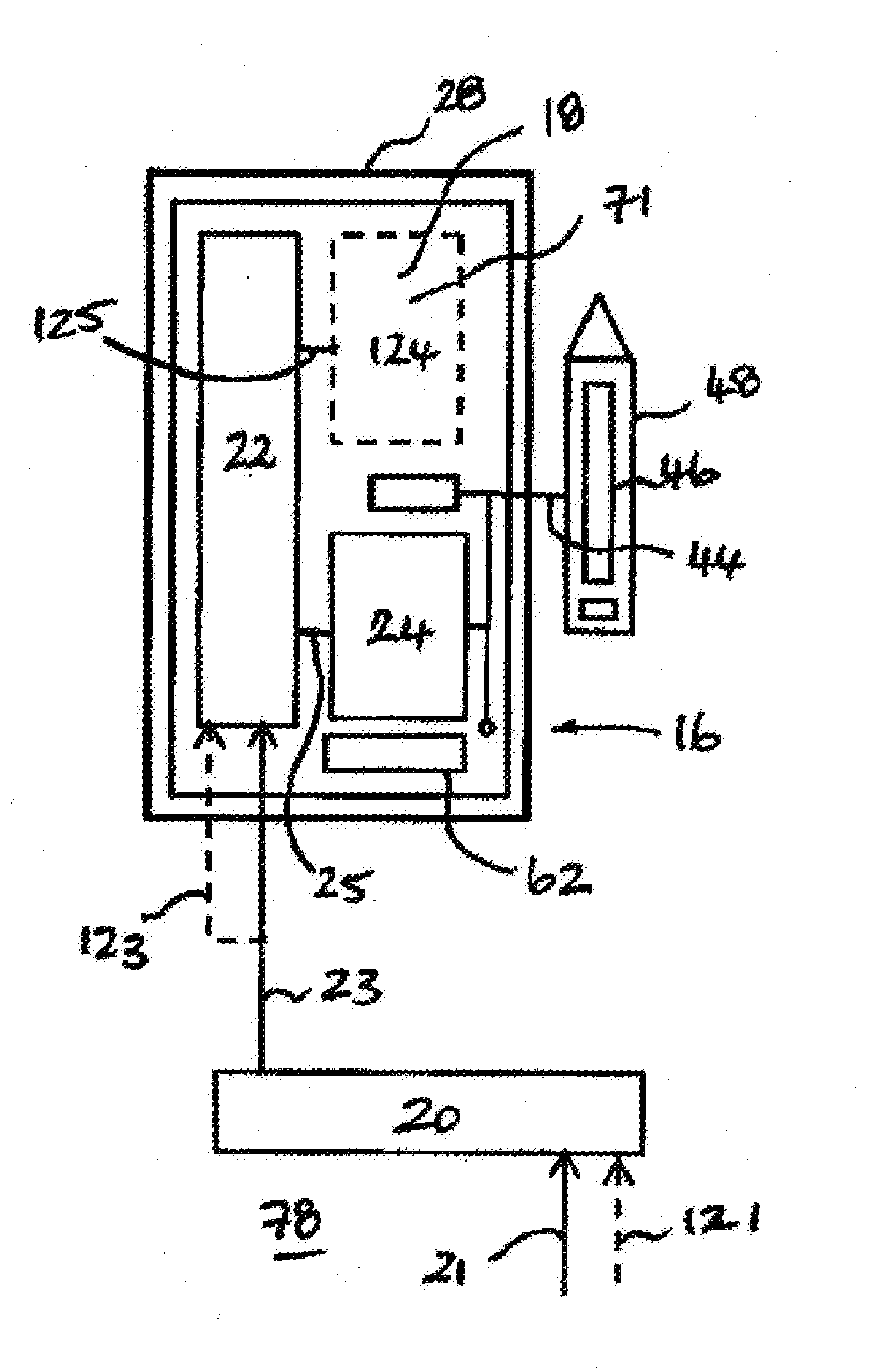

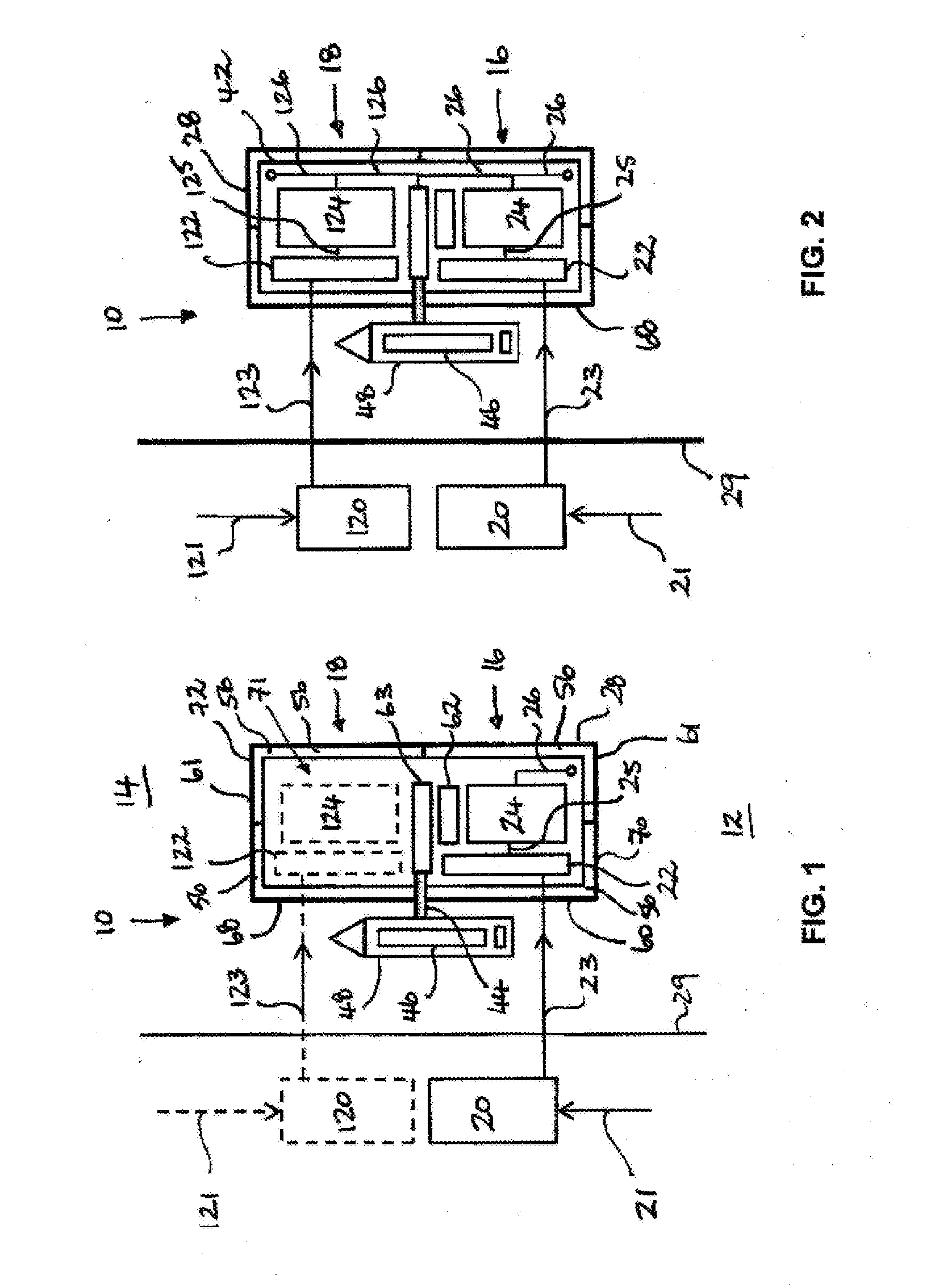

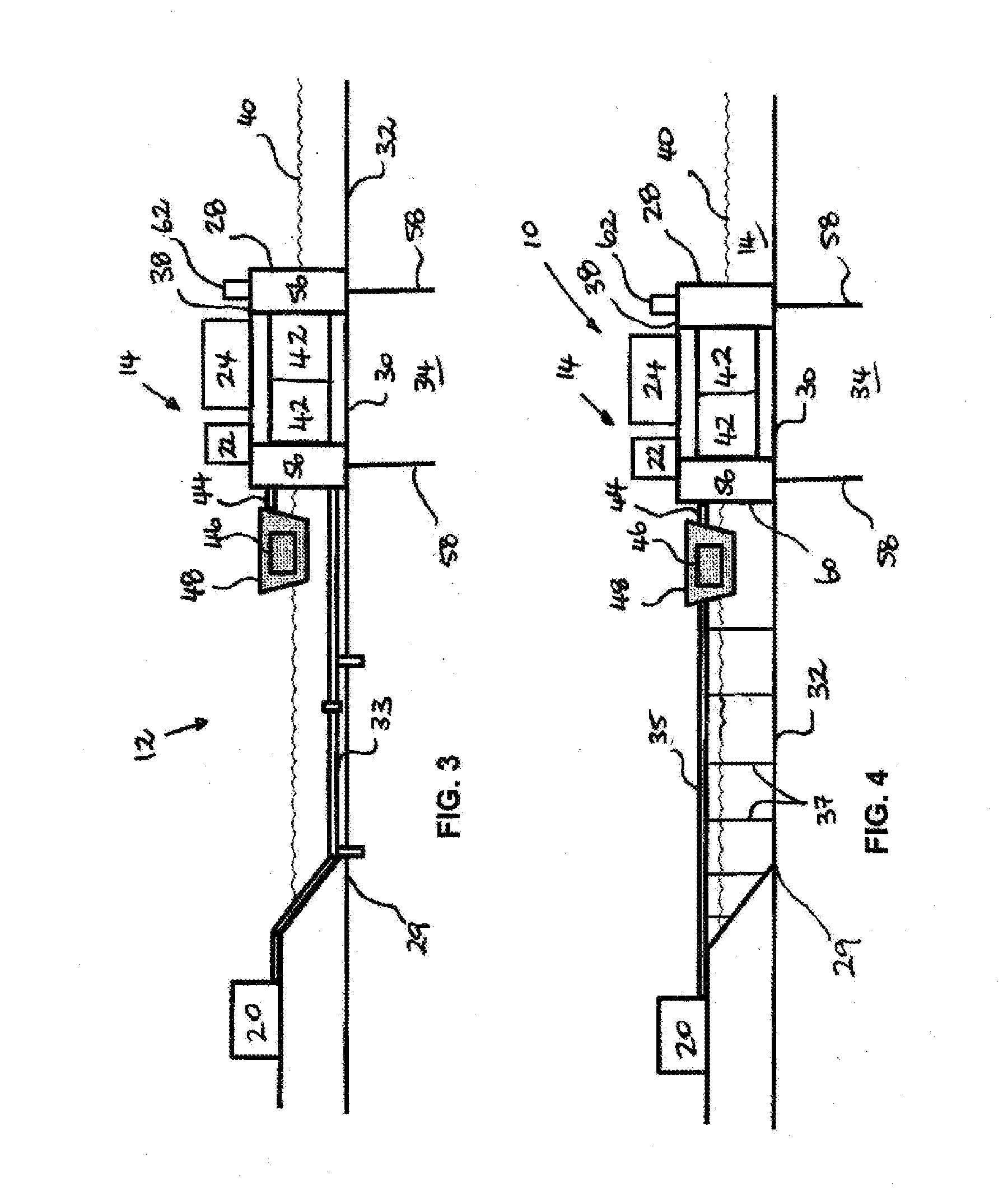

[0075]the present invention is now described with reference to FIGS. 1 to 4 in the context of the LNG processing plant being an LNG production plant. More specifically, there is provided a first phase LNG production plant for producing an initial plant capacity of LNG, the first phase LNG production plant comprising a plurality of spaced-apart facilities, each facility provided with plant equipment related to a pre-determined function associated with the liquefaction of LNG. The first phase LNG production plant includes at least the following facilities:[0076]a) a gas receiving facility for receiving a hydrocarbon stream comprising hydrocarbon gas and liquids and separating the liquids, including one or both of condensate and free water, from the hydrocarbon stream to produce a hydrocarbon feed gas stream for a gas pre-treatment facility;[0077]b) a gas pre-treatment facility for receiving a hydrocarbon feed gas stream from the gas receiving facility and removing contaminants from th...

second embodiment

[0100]the present invention is now described with reference to FIGS. 6 and 7 for which like reference numerals refer to like parts. As for FIGS. 1 and 2, the first phase LNG production plant 16 is shown in solid lines in FIG. 6 and FIG. 7 whilst the second phase LNG production plant 18 is shown in dotted lines in FIG. 6 with solid lines indicating that expansion has been completed in FIG. 7. The dotted lines in FIG. 6 represent the pre-allocated space 71 provided on the deck 38 of the structure 28 for subsequent expansion. In this embodiment the first phase gas receiving facility 20 is arranged on the deck 38 of the structure 28 with a pre-allocated space 71 being provided on the deck 38 of the structure 28 in anticipation of the subsequent addition of the second phase gas receiving facility 120 to be installed at a later time when expansion of the plant capacity is desired. The pre-allocated space 71 is arranged towards a first side 81 of the structure 28 with the pre-allocated spa...

third embodiment

[0101]the present invention is now described with reference to FIGS. 8 to 10 for which like reference numerals refer to like parts. As for FIGS. 1 and 2, the first phase LNG production plant 16 is shown in solid lines in FIGS. 8 to 10 whilst the second phase LNG production plant 18 is shown in dotted lines. The dotted lines in FIGS. 8 to 10 represent the pre-allocated space 71 provided on the deck 38 of the structure 28 for subsequent expansion. In this embodiment, the first phase gas receiving facility 20 is designed and sized of sufficient capacity to produce both the first phase hydrocarbon feed gas stream 23 and the second phase hydrocarbon feed gas stream 123. In other words, the first phase gas receiving facility 20 is capable not only of operating at the initial plant capacity prior to expansion, but is also capable of operating at the maximum plant capacity after one or more additional units are added to provide the second phase production plant 18. In FIG. 8, the first phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com