Toothed sprocket with elastic centering element

a technology of elastic centering element and sprocket, which is applied in the direction of couplings, hoisting equipment, transportation and packaging, etc., can solve the problems of low production cost of mass products, low quality fit manufacturing, and wiggle between the two components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

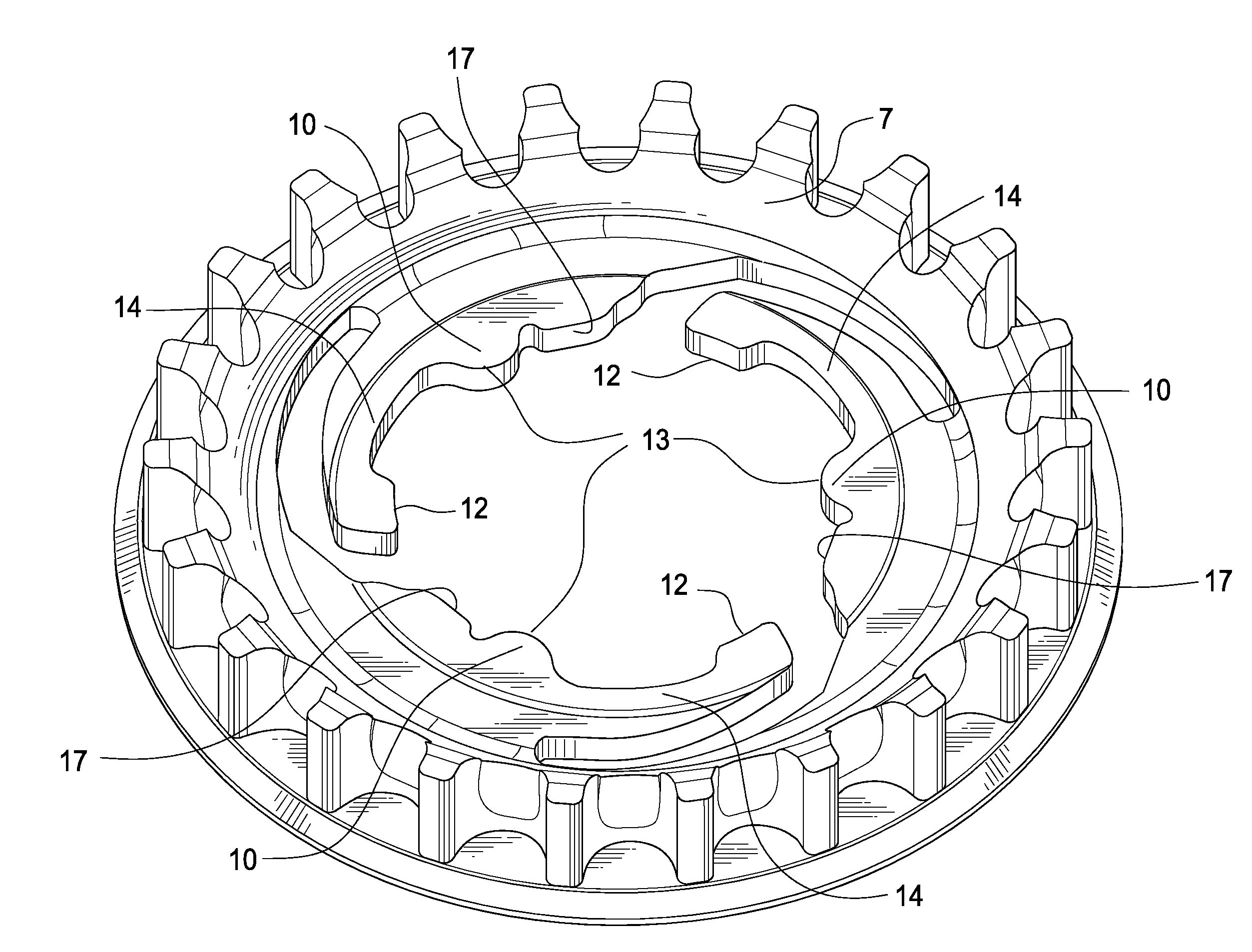

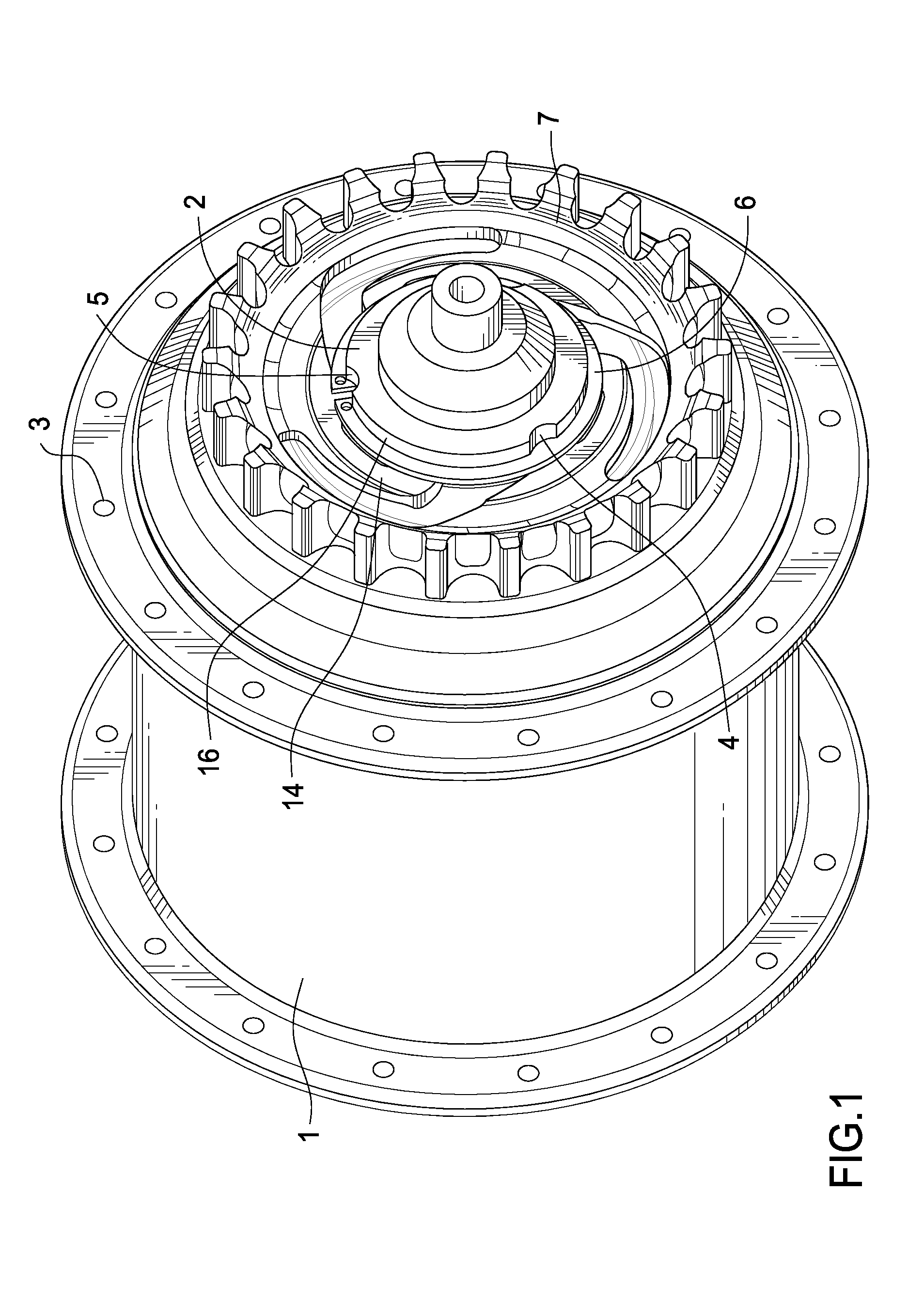

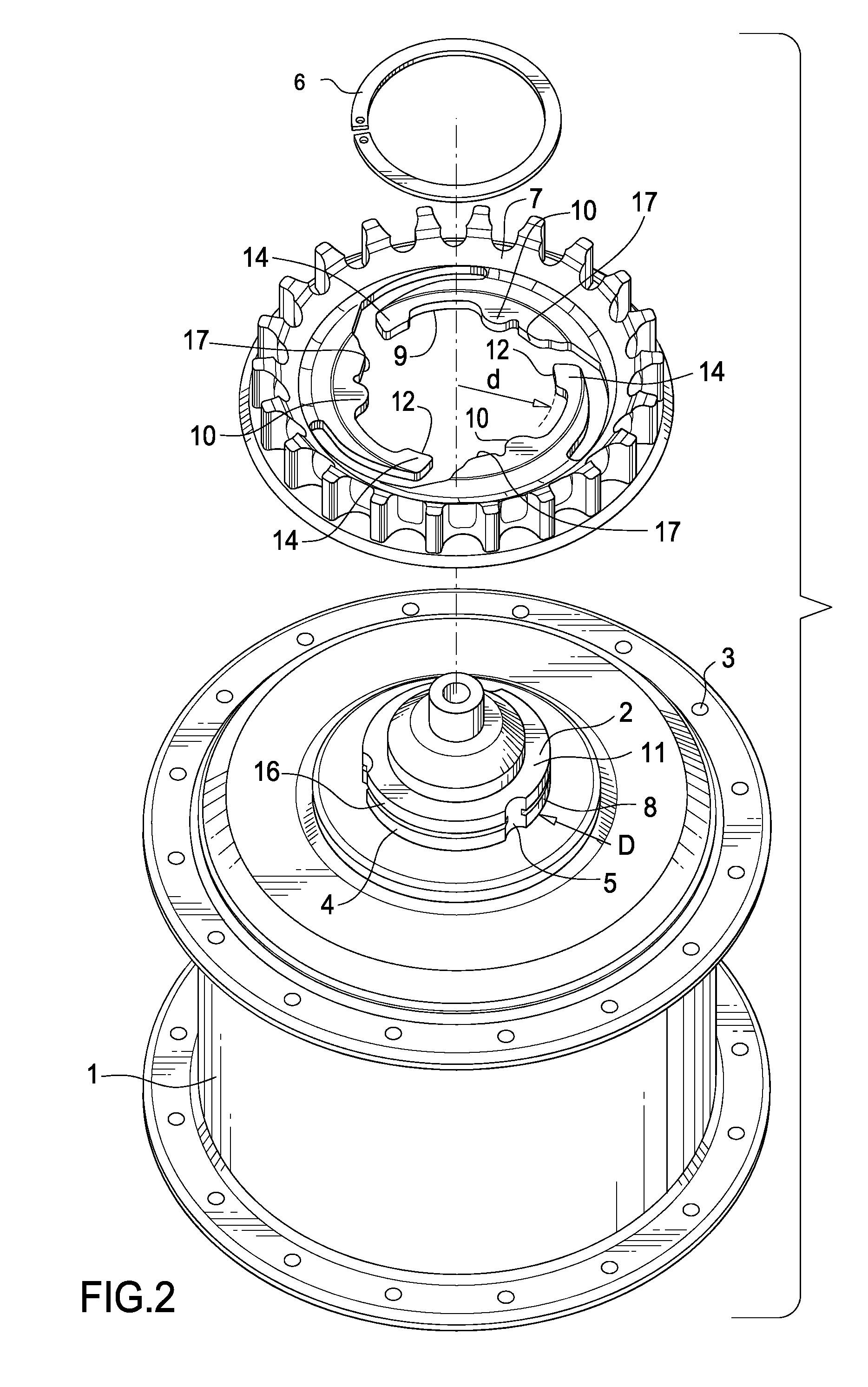

[0018]FIG. 1 shows a rear hub 1 of a bicycle without spokes or rim. Torque is transmitted to a toothed belt drive via a foot pedal or crank (not shown). The toothed belt transfers torques to the toothed sprocket 7, which in turn drives the input shaft 2.

[0019]This arrangement transmits torque via a shaft / hub connection 4 into the hub input shaft. A bicycle rim with tire (not shown) is driven by the rear hub 1 via spokes that are mounted inside the spoke holes 3. This is a known structure on a bicycle wheel. Toothed sprocket 7 is held axially on the input shaft 2 via a snap ring 6.

[0020]Sprocket 7 transmits torque via three receiving portions or grooves 5 which are engaged by projections 10. Cylinder-shaped outer surface 16 provides for correct centering of the toothed sprocket 7 on the input shaft 2. However, correct centering is only possible if the bore 9 of toothed sprocket 7 is seated without play in relation to the cylinder-shaped lateral surface 16. This is achieved in the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com