Electrode composite body, method of manufacturing electrode composite body, and lithium battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0040]In this embodiment, description will be given of an electrode composite body, a method of manufacturing the electrode composite body, and a lithium battery according to the invention.

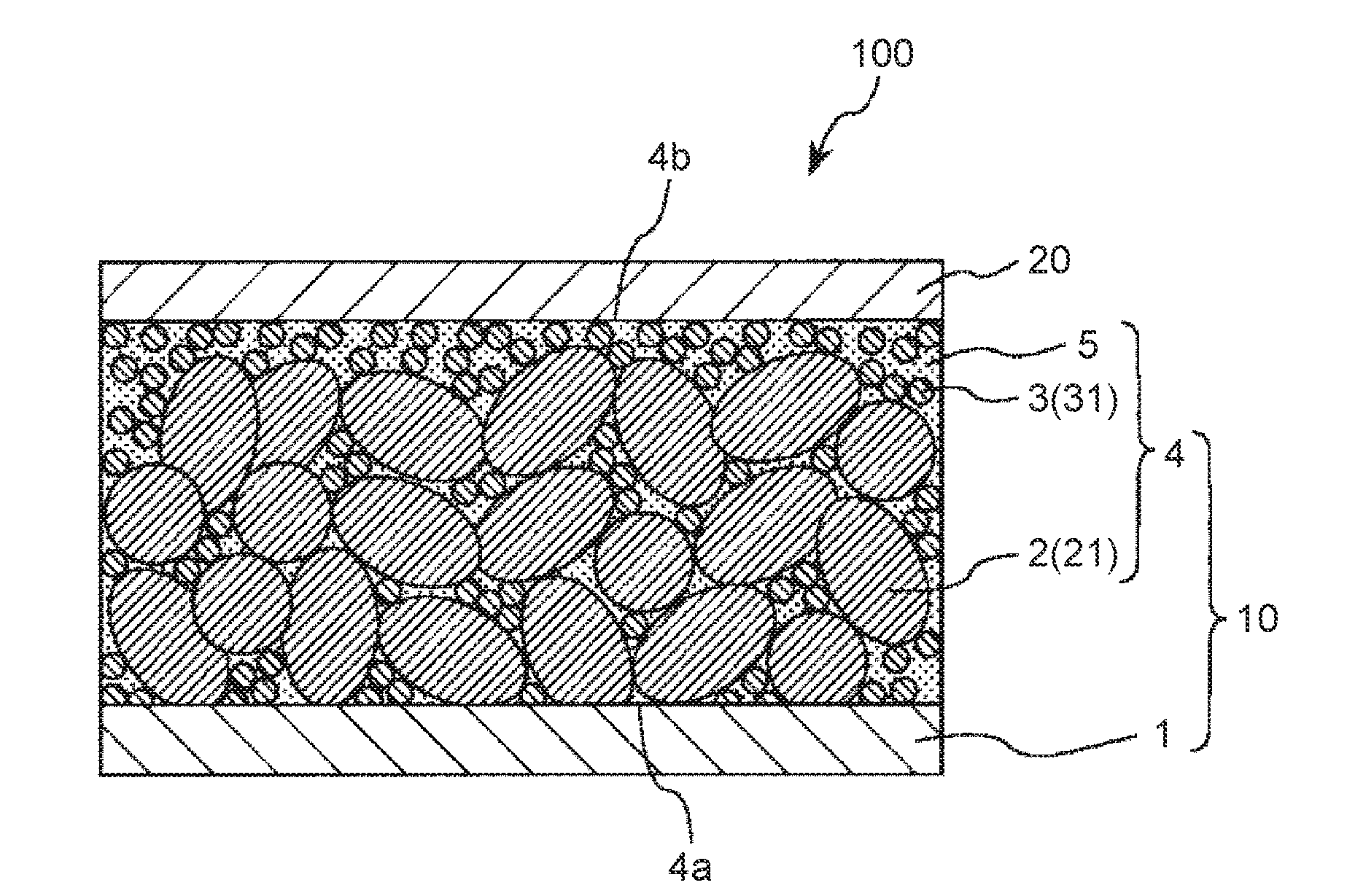

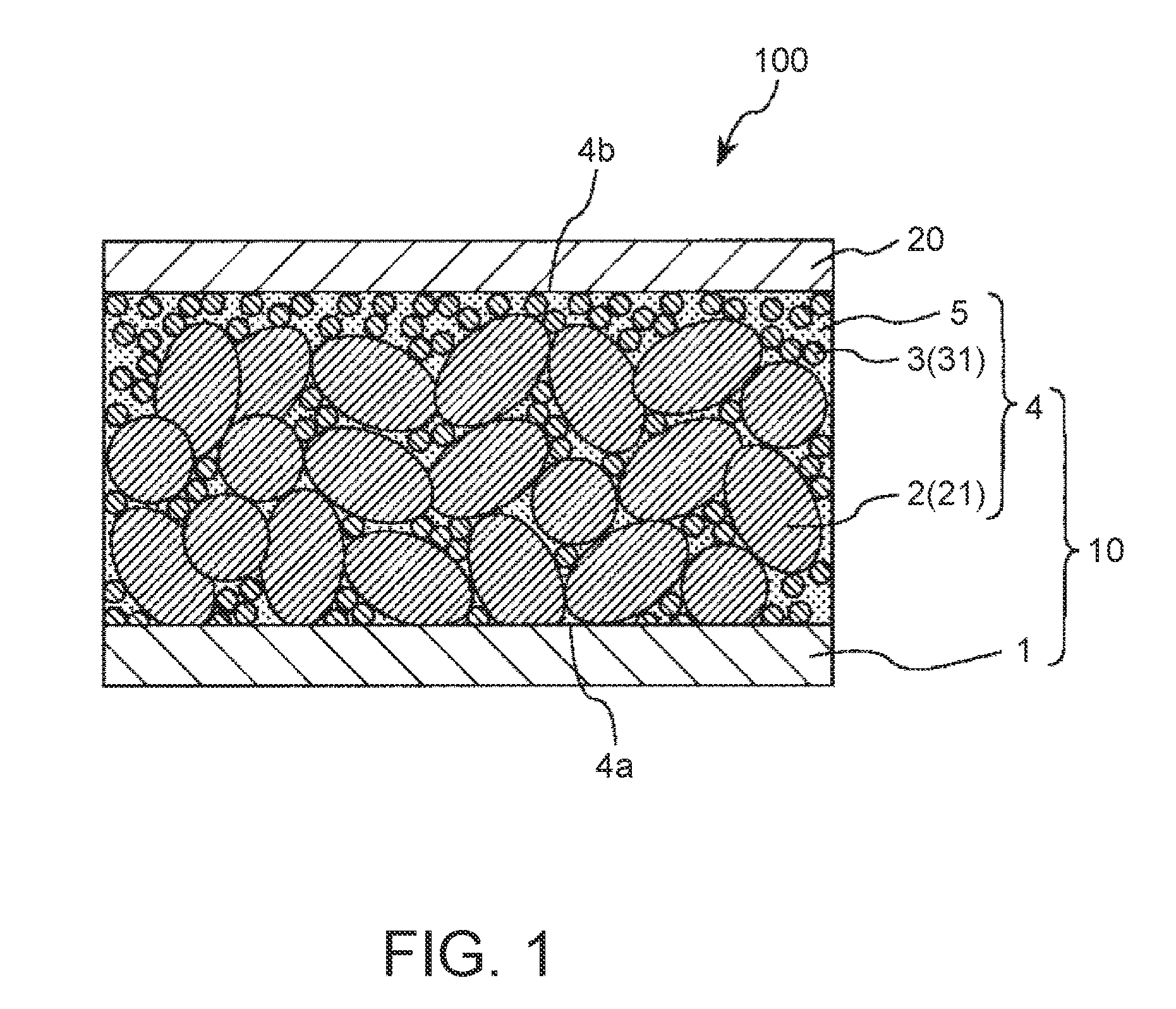

[0041]First, a lithium secondary battery 100, to which the lithium battery according to the invention is applied, will be described. FIG. 1 is a longitudinal cross-sectional view of the lithium secondary battery 100.

[0042]The lithium secondary battery 100 includes a stacked body 10, and an electrode 20 that is joined to the stacked body 10. The lithium secondary battery 100 is a so-called all-solid type lithium (ion) secondary battery.

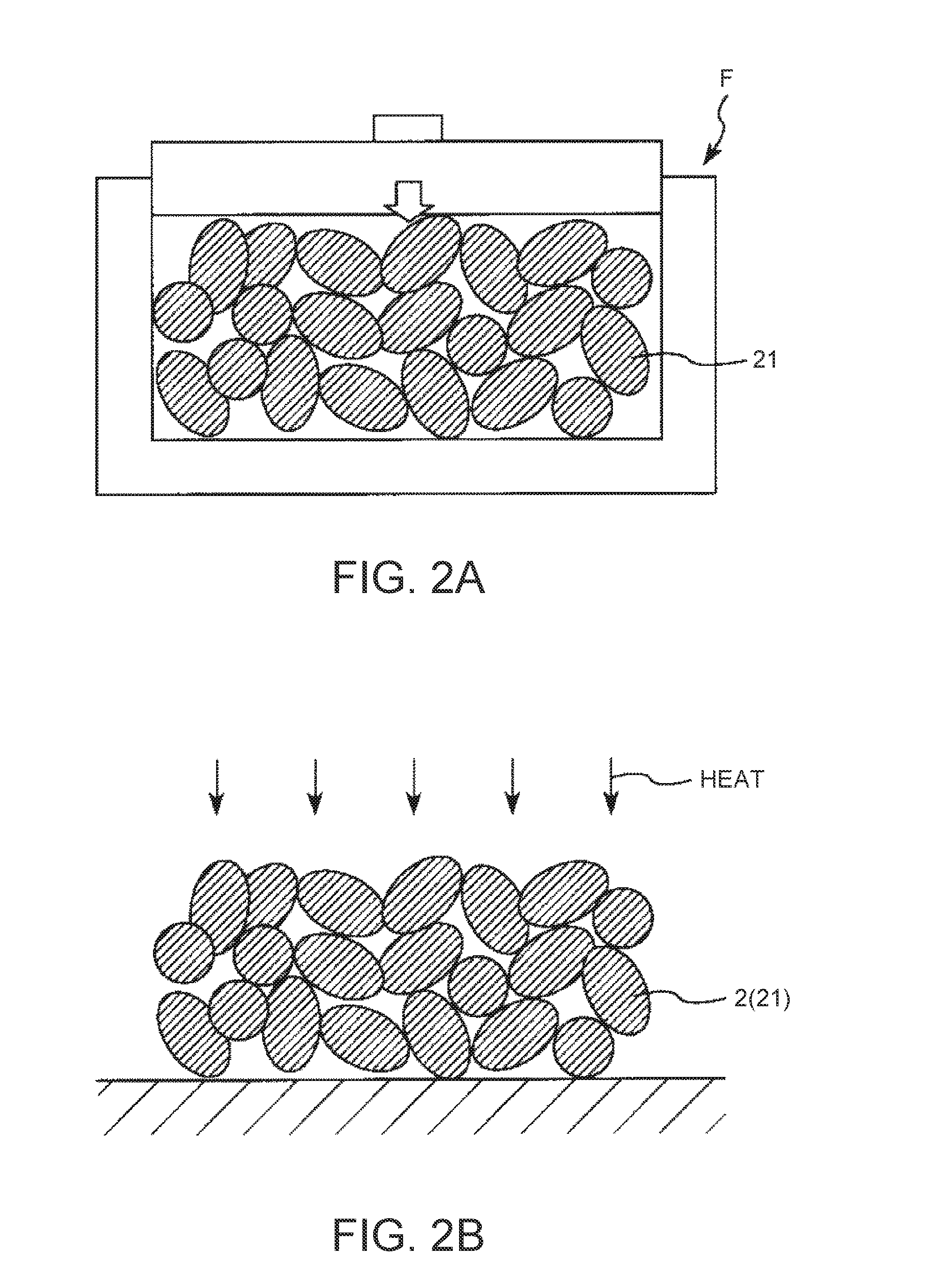

[0043]The stacked body 10 includes a current collector 1, an active material molded body 2, a first solid electrolyte layer 3, and a second solid electrolyte layer 5. In addition, in the following description, a configuration provided with the active material molded body 2, the first solid electrolyte layer 3, and the second solid electrolyte layer 5 is referred to a...

second embodiment

[0210]In this embodiment, description will be given of a lithium secondary battery having a structure different from that of the first embodiment. In addition, in the following embodiments including this embodiment, the same reference numerals will be given to the same constituent elements as the constituent elements in the first embodiment, and description thereof may not be repeated.

[0211]FIG. 9 is a longitudinal cross-sectional view of a lithium secondary battery according to a second embodiment.

[0212]In a lithium secondary battery 100A, a third solid electrolyte layer 6 is provided between the electrode composite body 4 and the electrode 20.

[0213]The third solid electrolyte layer 6, which is constituted by a third inorganic solid electrolyte and is formed through a vapor phase film formation, is formed between the electrode composite body 4 and the electrode 20.

[0214]When the third solid electrolyte layer 6 is provided, it is possible to prevent the current collector 1 and the e...

third embodiment

[0224]In this embodiment, description will be given of a lithium secondary battery having a structure different from that of the first embodiment and the second embodiment.

[0225]FIG. 10 is a longitudinal cross-sectional view of a lithium secondary battery according to a third embodiment.

[0226]In a lithium secondary battery 100B, an electrode composite body 4B having a configuration different from that of the electrode composite body 4 is provided between the current collector 1 and the electrode 20 to come into contact with the current collector 1 and the electrode 20.

[0227]The electrode composite body 4B includes an active material molded body 2B including the active material particles 21 and noble metal particles 22, the first solid electrolyte layer 3, and the second solid electrolyte layer 5.

[0228]In other words, the electrode composite body 4B includes the active material molded body 2B, which includes the active material particles 21 and the noble metal particles 22 which incl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap