Two-Stage Centrifugal Pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

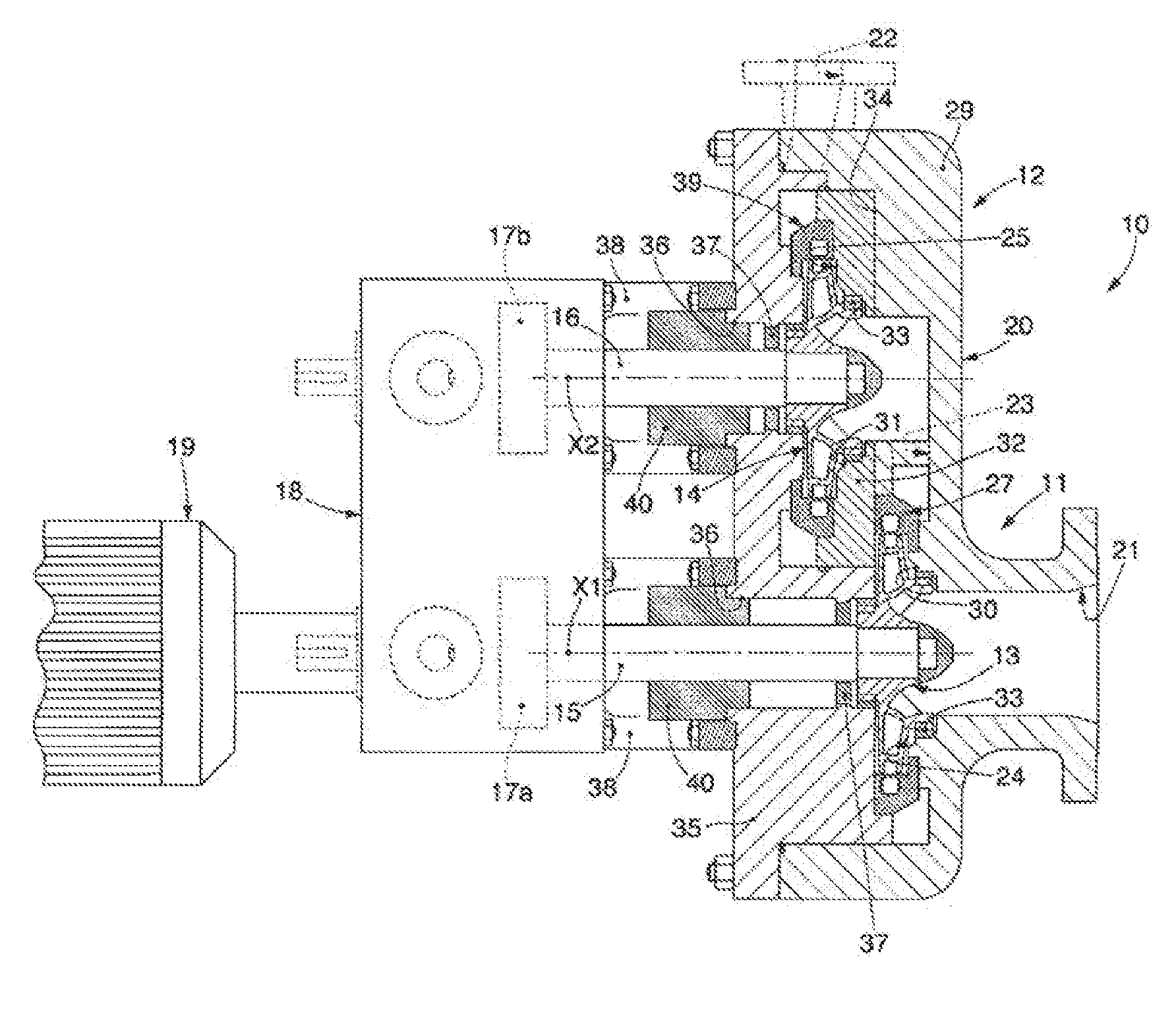

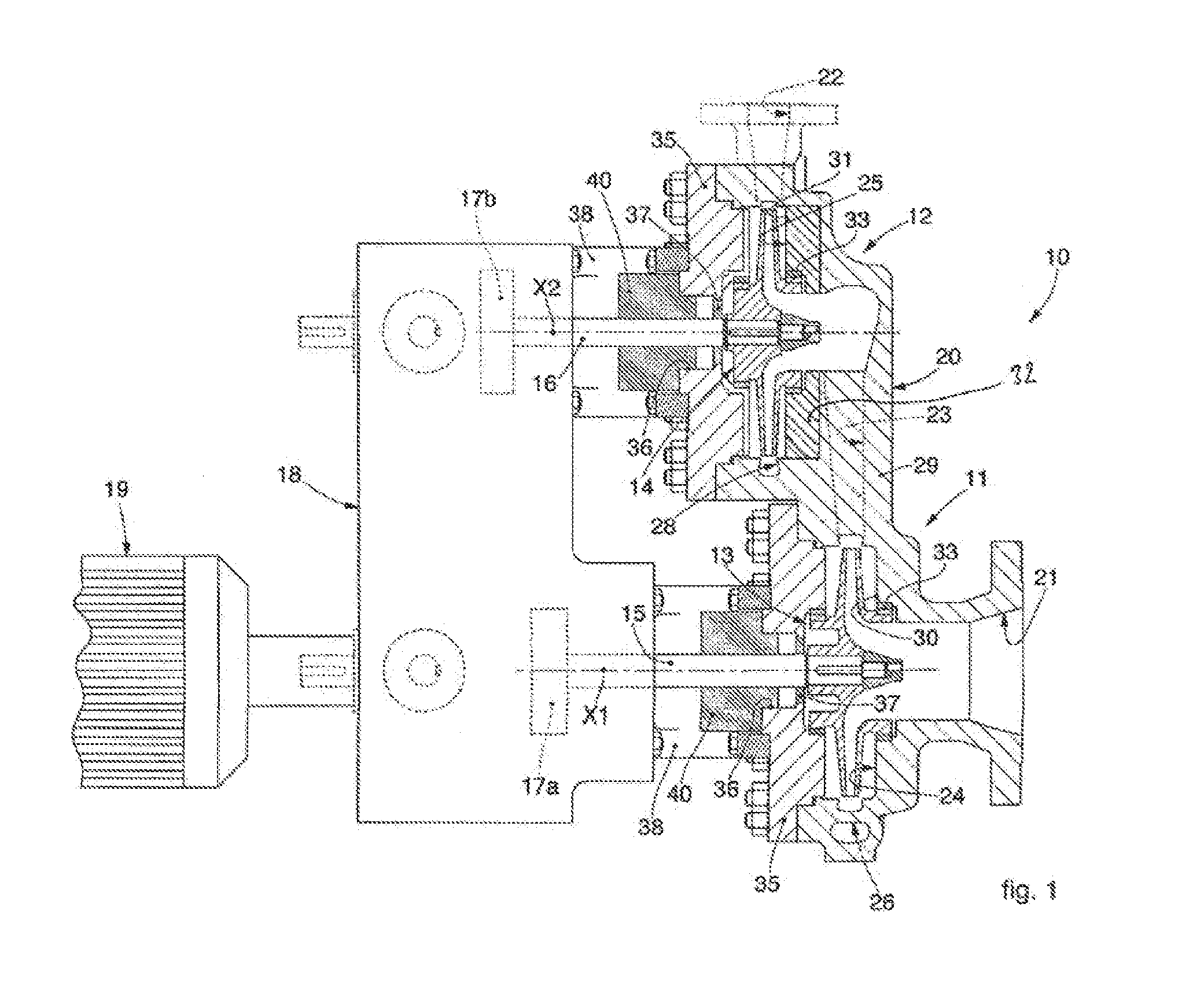

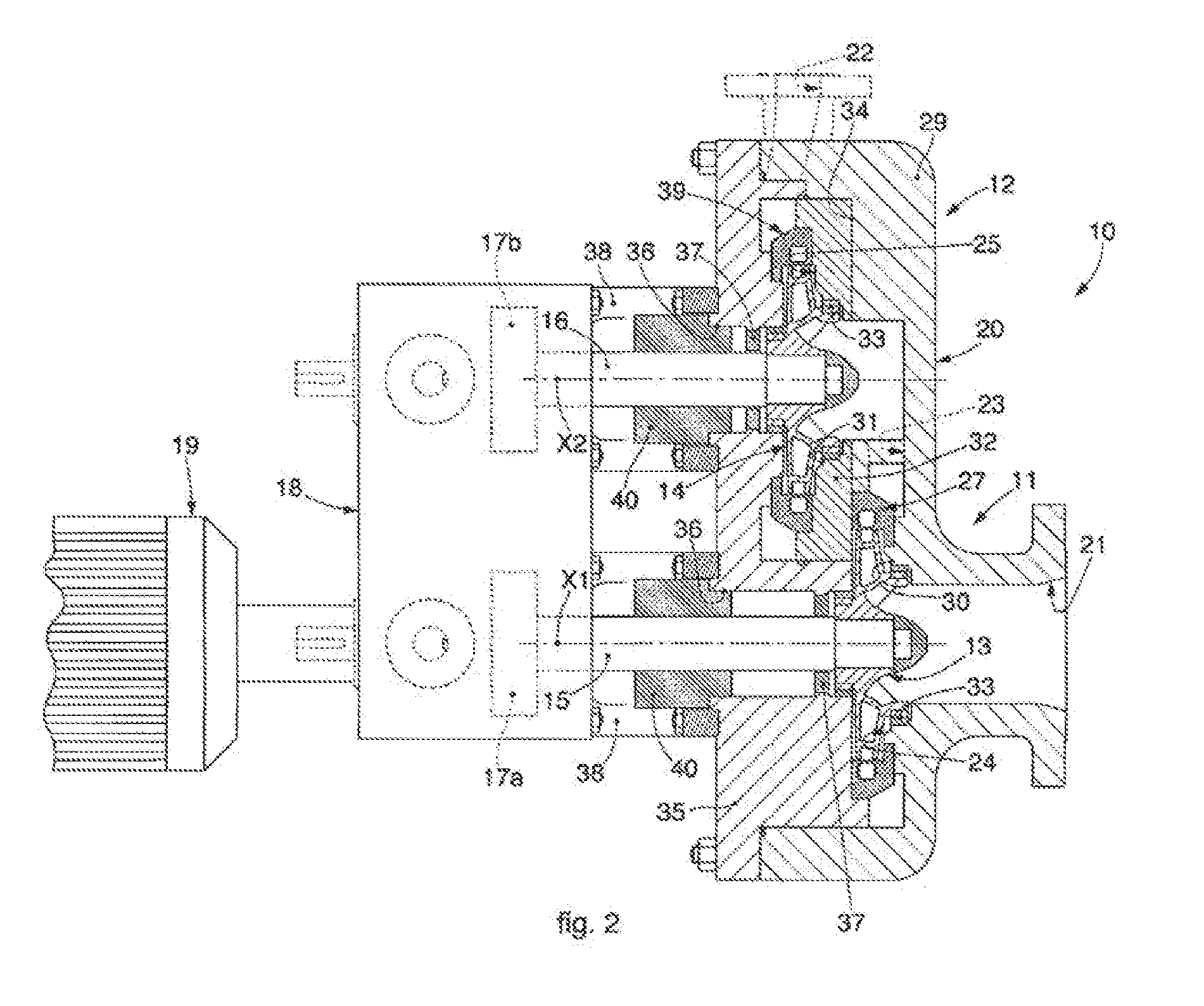

[0059]With reference to FIGS. 1, 2 and 3, a two-stage centrifugal pump is indicated in its entirety by the reference number 10. In each Figure, the same reference numerals have been used to denote like components.

[0060]The pump 10 comprises a first stage 11 and a second stage 12 which is hydraulically connected to the first stage 11—that is, the second stage 12 is configured to receive the fluid processed by the first stage 11, and to further increase the energy thereof, both in terms of pressure and in terms of speed (velocity).

[0061]The first stage 11 and the second stage 12 respectively comprise a first impeller 13 and a second impeller 14. The first impeller 13 and the second impeller 14 are each provided with a respective array of blades. The first impeller 13 and the second impeller 14 are mounted respectively on a first shaft 15 and on a second shaft 16, distinct from each other. The first shaft 15 and the second shaft 16 have respective axes of rotation X1 and respectively X...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com